Complex for preparing highly branched poly (4-methyl-1-pentene) material and preparation method thereof

The technology of a complex and trimethylaluminum is applied in the preparation of a complex of a highly branched poly-4-methyl-1-pentene material and the preparation field thereof, and can solve the problem of inability to catalyze the copolymerization of olefins and polar monomers, assist the The problem of expensive catalyst methylaluminoxane and high manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] This embodiment provides a diimine ligand, and its synthesis method is as follows.

[0031] Under nitrogen atmosphere and room temperature, add 20mL of toluene, 2,6-dipropyl-4-methoxyaniline (12mmol) into a 100mL branch bottle, and then add 12mL of trimethylaluminum (1.0M, 12mmol); The reaction temperature was raised to 110°C, and after 2 hours of reaction, the reaction temperature was lowered to room temperature, and then acenaphthylquinone (5mmol) was added; at this time, the reaction system changed from colorless to deep red, and a large amount of heat was emitted; at 110°C, continue React for 6 hours, then lower the temperature to 0°C, and terminate the reaction system with 5% sodium hydroxide ice solution; extract the organic phase with ethyl acetate, and then use anhydrous MgSO 4 Dry and spin the solvent under reduced pressure to obtain an orange oil; the product is separated through a silica gel column, eluent (petroleum ether: ethyl acetate = 15:1); recrystalliz...

Embodiment 2

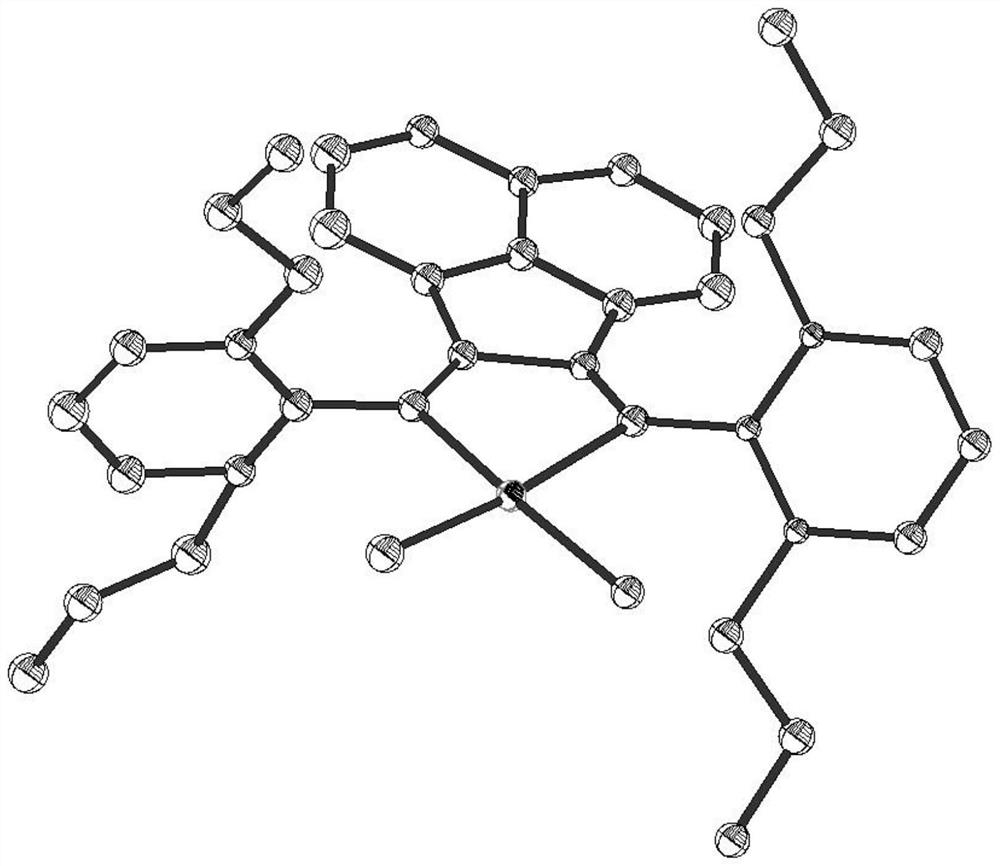

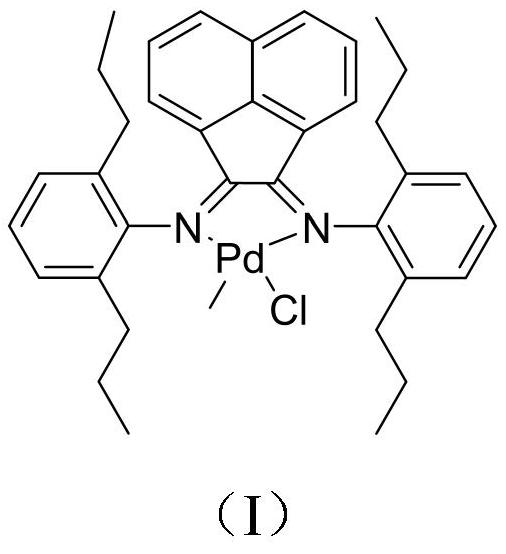

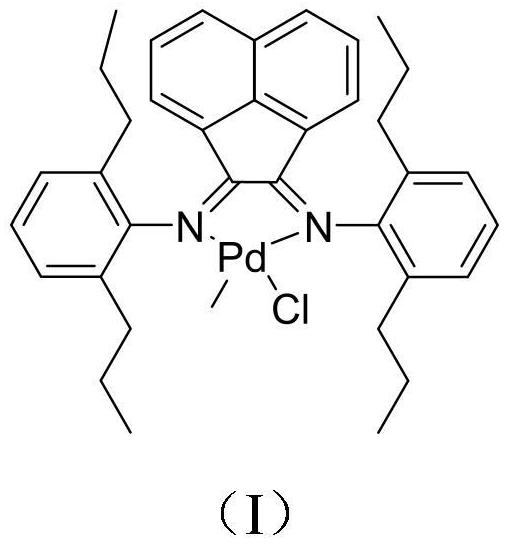

[0033] This example provides a diimine palladium complex, the synthesis method of which is as follows.

[0034] Under nitrogen protection, diimine ligand (0.5mmol), (COD)PdMeCl (0.6mmol) and 20mL of dichloromethane were added into a Schlenk bottle with a branch, and the reaction was stirred at room temperature for 12 hours, and then reduced at room temperature to The solvent was evaporated under pressure to about 5ml, and 20ml of n-hexane was added, at which point a large amount of precipitation occurred. Filter with G4 filter ball, wash the precipitate with 3×10 mL of n-hexane, and then vacuum-dry to obtain a yellow solid powder diimide palladium complex with a yield of 78.6%.

Embodiment 3

[0036] This embodiment provides a highly branched poly(4-methyl-1-pentene), the preparation method of which is as follows.

[0037] All the glass instruments and magnets used for stirring were dried in an oven (120°C), and all polymerization experiments were carried out under anhydrous and oxygen-free conditions. Under continuous vacuuming, bake a 250mL branched-mouthed round-bottom flask under an infrared lamp at 150°C for more than 1 hour to remove all moisture and air; replace it with nitrogen twice and then fill it with nitrogen to normal pressure; keep the water bath at 30 ℃, add metered amount of chlorobenzene, stir to dissolve and inject 2M monomer and 10 μmol diimine palladium complex dissolved in 2 mL of dichloromethane. Stop the reaction after polymerizing to 4h, use Et 3 After SiH terminated, it was precipitated in methanol. The precipitated polymer was dissolved in petroleum ether, separated by silica gel column, concentrated, and precipitated in methanol. The obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Number average molecular weight | aaaaa | aaaaa |

| Number average molecular weight | aaaaa | aaaaa |

| Number average molecule | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com