MgO-loaded activated carbon as well as preparation method and application thereof

A technology of activated carbon and solution, applied in chemical instruments and methods, other chemical processes, special treatment targets, etc., can solve problems such as limited boron ion adsorption capacity, secondary pollution, etc., achieve circular economic benefits and environmental benefits, and adapt to low temperature Strong ability to improve the effect of adsorption and removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

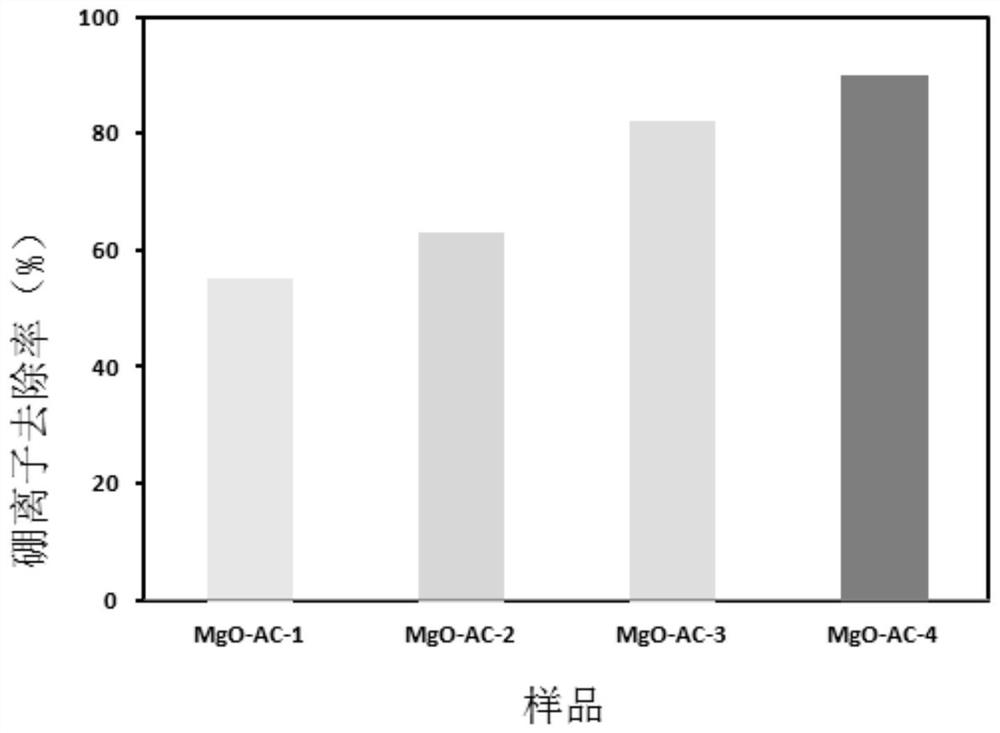

Examples

Embodiment 1

[0039] (a) Set the specific surface area to 1200m 2 / g of coconut shell activated carbon is screened, and after sieving, 10g of coconut shell activated carbon with a particle size of 20-60 meshes is weighed, and vacuum-dried at 105°C for 4h, and the moisture content of the dried material is ≤1%. Add the dried granular activated carbon into the round bottom flask, then add 75mL 0.08mol / L nitric acid solution, ultrasonically shake for 2h, filter and recover the solvent, wash the solid product repeatedly with deionized water several times, and then vacuum dry it at 75°C for 8h. Obtain preoxidized activated carbon.

[0040] (b) Add 100mL of 0.03mol / L magnesium chloride solution to the pre-oxidized activated carbon, stir well, add 20mL of 0.010mol / L polyethylene glycol solution dropwise at a rate of 1mL / min to the resulting mixture, at room temperature supplemented with vigorous Magnetic stirring (speed>800r / min). After the polyethylene glycol solution was added dropwise, ultraso...

Embodiment 2

[0043] (a) Set the specific surface area to 1200m 2 / g of coconut shell activated carbon is screened, and after sieving, 10g of coconut shell activated carbon with a particle size of 20-60 meshes is weighed, and vacuum-dried at 105°C for 4h, and the moisture content of the dried material is ≤1%. Add the dried granular activated carbon into the round bottom flask, then add 75mL 0.08mol / L nitric acid solution, ultrasonically shake for 2h, filter and recover the solvent, wash the solid product repeatedly with deionized water several times, and then vacuum dry it at 75°C for 8h. Obtain preoxidized activated carbon.

[0044] (b) Add 100mL of 0.03mol / L magnesium chloride solution to the pre-oxidized activated carbon, stir evenly, add 20mL of 0.010mol / L polyethylene glycol solution dropwise at a rate of 1mL / min to the resulting mixture, and add Vigorous magnetic stirring (speed>800r / min). After the polyethylene glycol solution was added dropwise, ultrasonically oscillate for 1 h, t...

Embodiment 3

[0047] (a) Set the specific surface area to 1400m 2 / g of bamboo activated carbon was sieved, and after sieving, 10g of bamboo activated carbon with a particle size of 20-60 mesh was weighed, and vacuum-dried at 105°C for 4h, and the moisture content of the dried material was ≤1%. Add the dried granular activated carbon into a round bottom flask, then add 120mL 0.1mol / L hydrogen peroxide solution, ultrasonically shake for 2h, filter and recover the solvent, wash the solid product repeatedly with deionized water several times, and then vacuum dry it at 75°C for 8h. Obtain preoxidized activated carbon.

[0048] (b) Add 120 mL of 0.05 mol / L magnesium chloride solution to the pre-oxidized activated carbon subsequently, stir well, add 30 mL of 0.010 mol / L polyethylene glycol solution dropwise at a rate of 1 mL / min to the resulting mixture, and assist Stir vigorously with magnetic force (speed>800r / min). After the polyethylene glycol solution was added dropwise, ultrasonically osc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com