Pig raising waste treatment and comprehensive utilization method

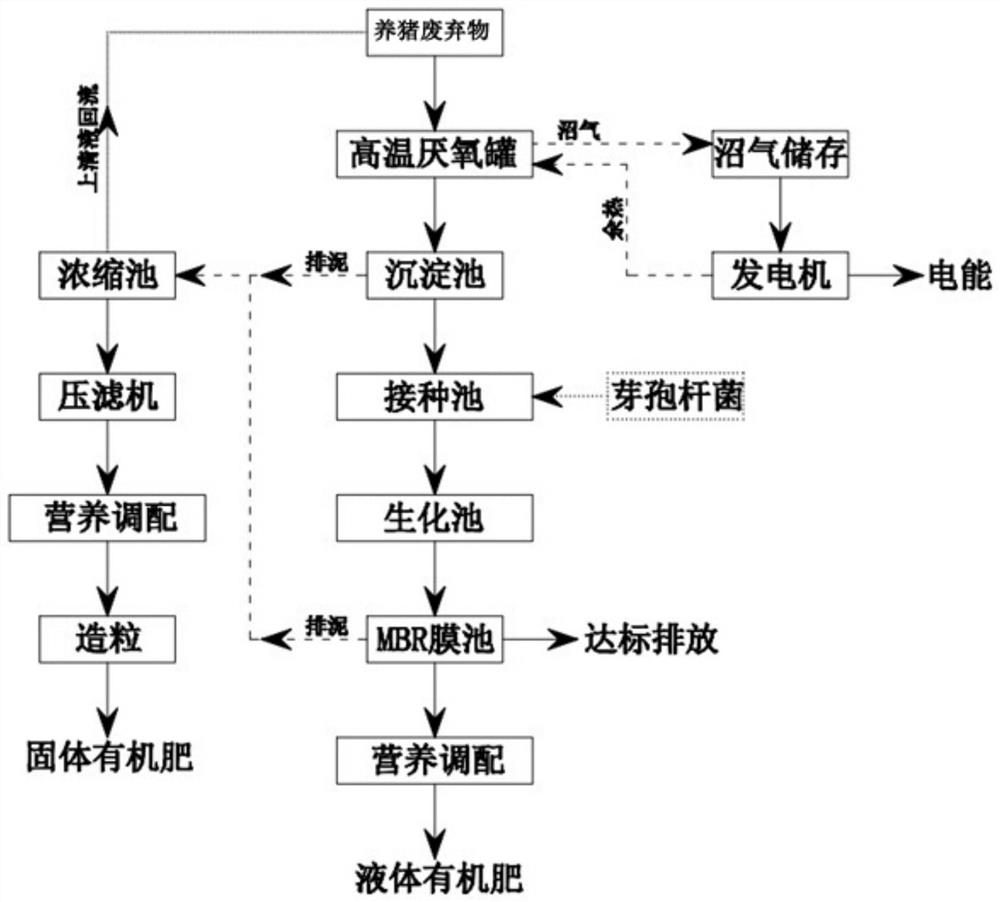

A technology of waste and inoculation pool is applied in the field of pig waste treatment and comprehensive utilization, which can solve the problem that pig waste disposal is easily affected by external conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] This embodiment provides a method for the treatment and comprehensive utilization of pig raising waste, comprising the following steps:

[0029] (1) Get the pig raising waste that contains excrement, urine and sewage, add in the high-temperature anaerobic tank, in order to prevent the agglomeration and precipitation of solid matter in the reactor, the temperature is controlled at 50-55 ° C, and through 25 days of full reaction; The pig waste does not undergo solid-liquid separation. After being completely mixed, it directly enters the high-temperature anaerobic reactor to make full use of a large amount of organic matter in the feces, balance the carbon-nitrogen ratio of the biochemical reaction, and improve the biodegradability of the mixture. At this time, the solids in the mixture High content of pollutants, high concentration of pollutants, large gas production, can greatly reduce the content of organic matter, and effectively kill pathogenic bacteria and insect eggs...

Embodiment 2

[0039] This embodiment provides a method for the treatment and comprehensive utilization of pig raising waste, comprising the following steps:

[0040] (1) Take the pig-raising waste containing feces, urine and sewage, add it to the high-temperature anaerobic tank, and control the temperature at 55 ° C. After 15 days of full reaction; the anaerobic microorganisms in the high-temperature anaerobic reactor convert the organic matter in the water into Biogas, the generated biogas is passed into the biogas storage tank for storage, and the heat generated in the high-temperature anaerobic tank is used for the generator to generate electricity.

[0041] (2) The mixture output from the high-temperature anaerobic tank enters the sedimentation tank for solid-liquid separation; the separated sludge is an inorganic residue rich in nitrogen and phosphorus, and the nitrogen in the sludge is 7.28g / kg, phosphorus 12.88g / kg, Potassium is 8.88g / kg. It enters the sludge thickening tank to conce...

Embodiment 3

[0046] This embodiment provides a method for the treatment and comprehensive utilization of pig raising waste, comprising the following steps:

[0047] (1) Take the pig-raising waste containing feces, urine and sewage, add it to the high-temperature anaerobic tank, control the temperature at 50 ° C, and fully react through 30 days; the anaerobic microorganisms in the high-temperature anaerobic reactor convert the organic matter in the water into Biogas, the generated biogas is passed into the biogas storage tank for storage, and the heat generated in the high-temperature anaerobic tank is used for the generator to generate electricity.

[0048] (2) The mixture output from the high-temperature anaerobic tank enters the sedimentation tank for solid-liquid separation; the separated sludge is an inorganic residue rich in nitrogen and phosphorus, and the nitrogen in the sludge is 7.31g / kg, phosphorus 12.54g / kg, Potassium is 8.68g / kg. It enters the sludge thickening tank to concentr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com