Enzyme solution with better enzyme activity ratio of beta-mannase to alpha-galactosidase as well as preparation method and application of enzyme solution

A mannanase and galactose technology, applied in the directions of microorganism-based methods, methods using microorganisms, biochemical equipment and methods, etc., can solve the problem of reducing production costs, low β-mannosidase activity, and no good results. effect and other issues, to achieve the effect of reducing production costs and improving yields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Trichoderma reesei uses microcrystalline cellulose and melibiose as carbon sources to ferment and produce enzymes, including the following steps:

[0043] (1) Enzyme production medium composition (g / L): glucose 1.0, microcrystalline cellulose 25.0 or melibiose 25.0, ammonium sulfate 4.72, urea 2.15, potassium dihydrogen phosphate 2.0, anhydrous calcium chloride 0.3, heptahydrate Magnesium sulfate 0.3, ferrous sulfate heptahydrate 0.005, manganese sulfate heptahydrate 0.0016, zinc sulfate heptahydrate 0.0014, cobalt chloride 0.002. Add 50 mL of 1 mol / L sodium citrate buffer to adjust the pH of the medium to 4.8.

[0044] (2) Enzyme production by fermentation

[0045] Put the above 50mL medium into a 250mL Erlenmeyer flask with a cotton plug, inoculate Trichoderma reesei spores according to 10% inoculum size, and place them in a constant temperature shaker at 28-30°C and 170 rpm for 4 days. After the cultivation, the culture solution was centrifuged at 3000 rpm for 10 m...

Embodiment 2

[0048] Compound enzymatic hydrolysis of mannanase and galactosidase to prepare small molecule galactomannans and galactomannoligosaccharides, the steps are as follows:

[0049] (1) Directed enzymatic hydrolysis of galactomannan

[0050] The leguminous seeds containing galactomannan (Tianjing) were mechanically crushed to 20-100 mesh, added distilled water at a solid-to-liquid ratio of 1:50, extracted at 50°C for 24 hours, and then centrifuged at 10,000 rpm for 10 minutes The supernatant was obtained, and absolute ethanol was added to the supernatant, and the obtained precipitate was vacuum-dried to obtain galactomannan powdery solid.

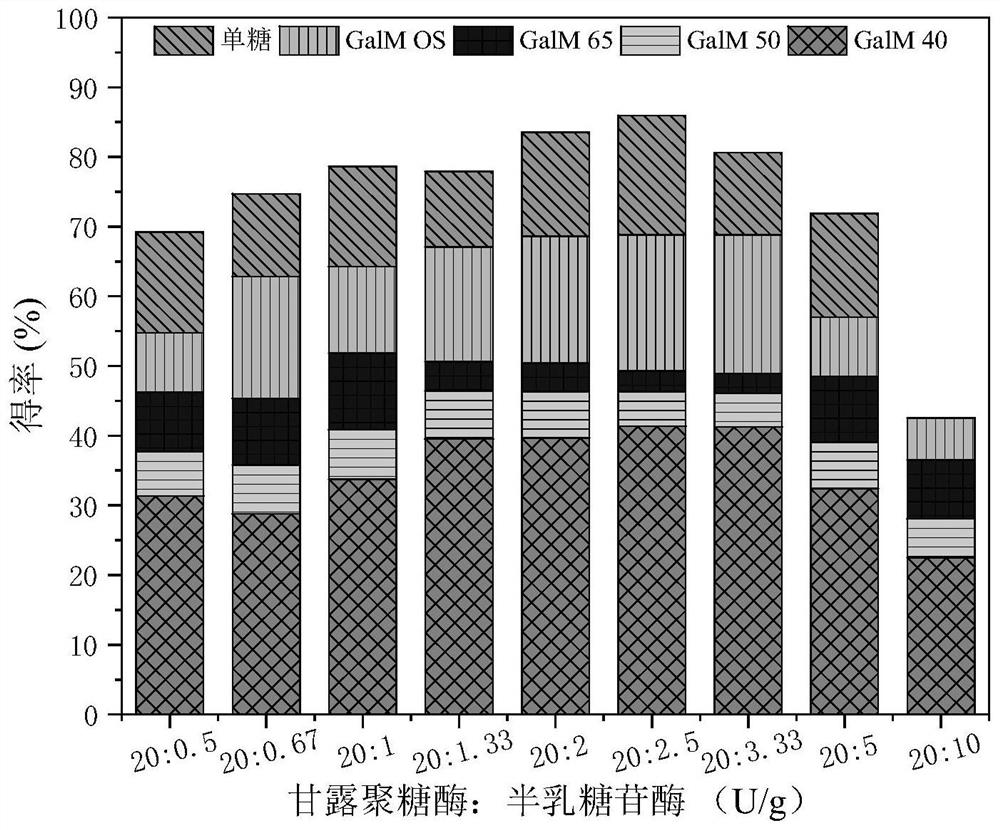

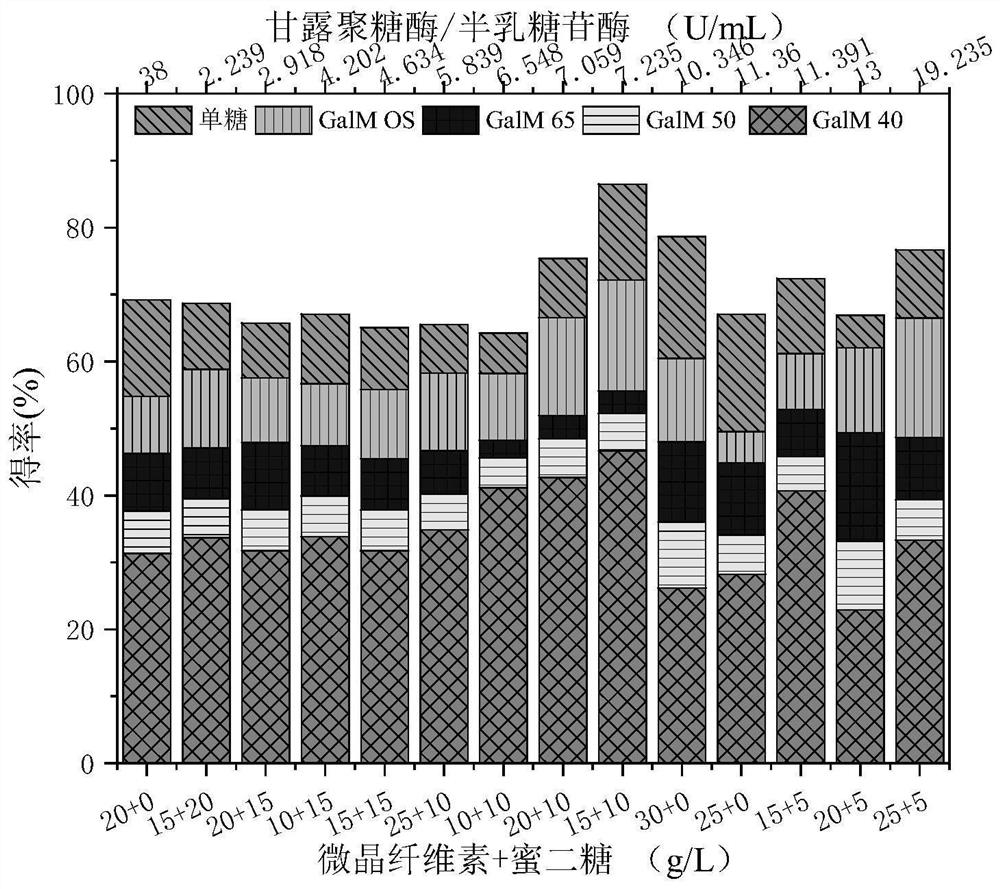

[0051] The enzyme liquid 1 and enzyme liquid 2 obtained in Example 1 were compounded so that the enzyme activity ratios of β-mannanase and α-galactosidase were 2, 4, 6, 8, 10, 12, 15, 20, 30, 40. Then weigh 20.0 g of the above-mentioned galactomannan in a 2L enzyme reaction tank, add distilled water, enzyme solution, and 1mol / L citric acid buf...

Embodiment 3

[0058] The compound production enzyme of microcrystalline cellulose and melibiose, its steps are as follows:

[0059] (1) The enzyme-producing medium was the same as in Example 1, wherein the substrate was replaced by a mixture of microcrystalline cellulose and melibiose in different proportions, and the sum of the concentrations of the two substrates was 20.0, 25.0, 30.0, and 35.0 g / L, respectively.

[0060] (2) The method for producing enzyme by fermentation is the same as in Example 1.

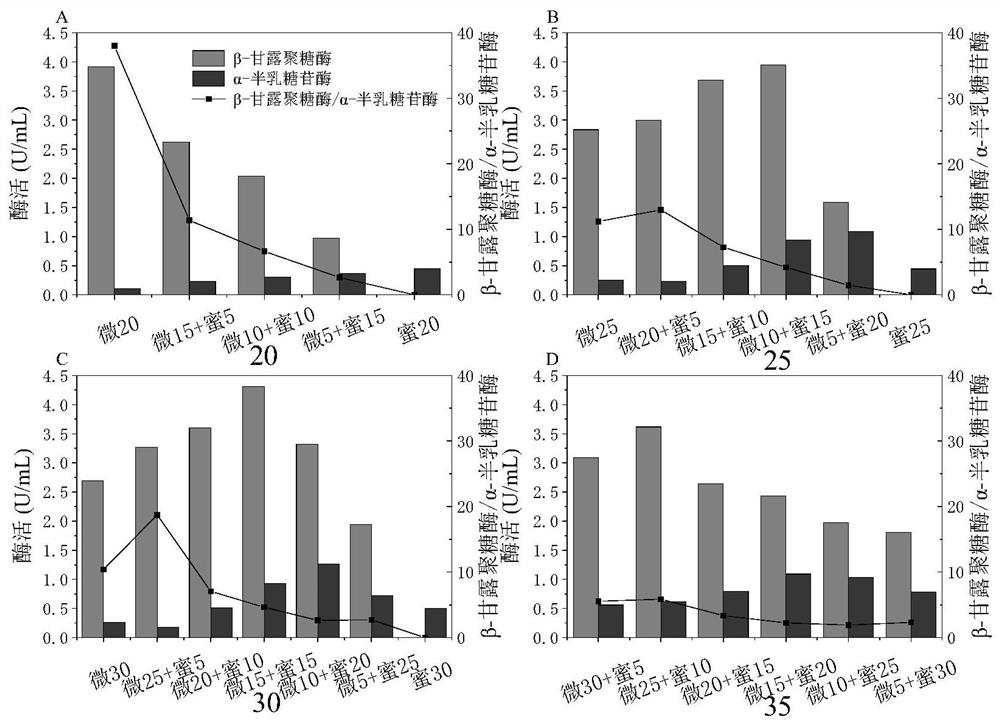

[0061] The result is as figure 2 As shown, when the total substrate concentration was 20g / L, with the continuous increase of melibiose, the activity of β-mannanase decreased continuously. But when the total substrate concentration was 25, 30, 35g / L, with the continuous increase of melibiose, the enzyme activity of β-mannanase showed a trend of first increasing and then decreasing. When the total substrate concentration was 25g / L, microcrystalline cellulose was 20g / L and melibiose was 5g / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com