Moisture-proof packaging paper and preparation method thereof

A technology of wrapping paper and paper, applied in the direction of wrapping paper, wrapping paper, packaging, etc., can solve the problems of weak barrier, easy delamination, cracking, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Add 10 g of PVA0588 into 100 mL of deionized water, stir and dissolve at 90° C. for 6 h at a stirring speed of 200 rpm to obtain a PVA solution.

[0031] (2) Add 6 g of glyceryl tristearate (melting point 56° C.) and 0.9 g of Tween 80 (emulsifier) to the obtained PVA solution, and emulsify for 2 h at a stirring speed of 1000 rpm.

[0032] (3) Use a high-shear emulsifier to homogenize the composite emulsion, control the shear speed to 20000 rpm, and shear the time for 3-5 minutes to obtain the composite emulsion.

[0033] (4) Coat the composite emulsion evenly on the wrapping paper, and dry it at different temperatures between room temperature and 150°C.

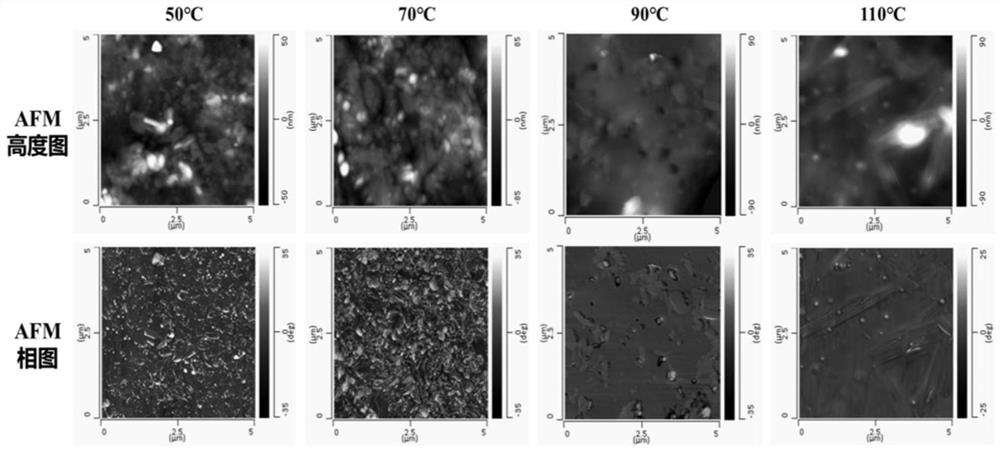

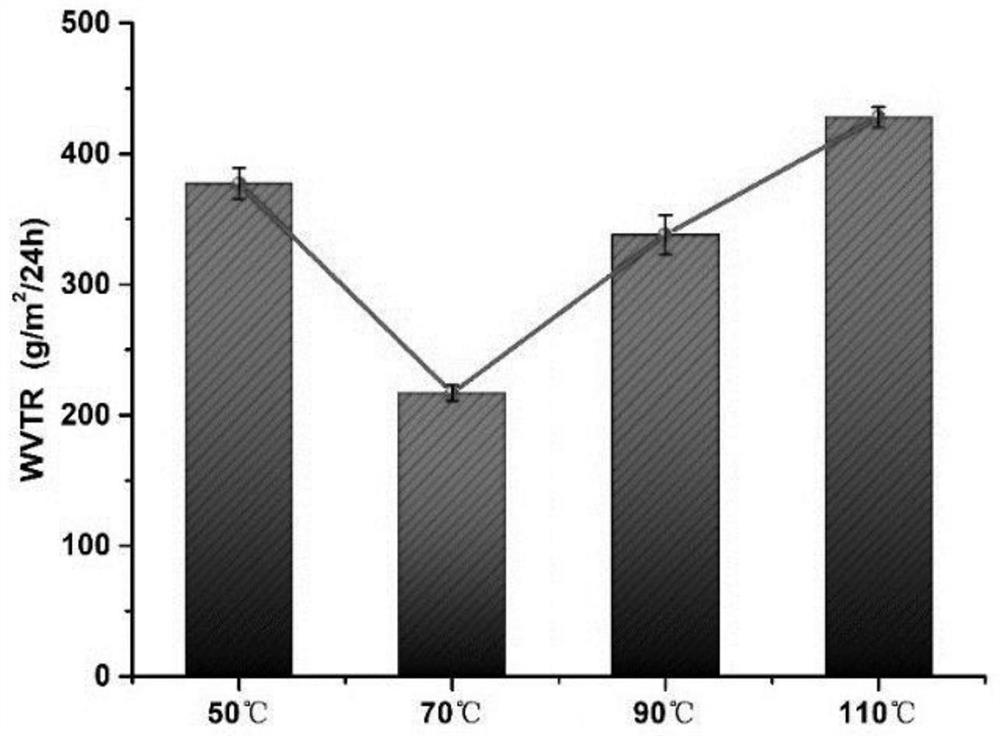

[0034] Observe the microscopic morphology of the coating at different drying temperatures by atomic force microscopy (AFM), select several typical temperature values, and the results are as follows figure 1 shown;

[0035] It can be seen from the figure that when the drying temperature is slightly higher than t...

Embodiment 2

[0041] (1) Add 5 g of PVA1799 to 100 mL of deionized water, stir and dissolve at 90° C. for 6 h at a stirring speed of 200 rpm to obtain a PVA solution.

[0042] (2) Add 5 g of beeswax (melting point 67° C.) and 0.1 g of cetyltrimethylamine bromide (emulsifier), and emulsify for 1 h at a stirring speed of 1000 rpm.

[0043] (3) Use a high-shear emulsifier to homogenize the composite emulsion, control the shear speed to 20000 rpm, and shear the time for 3-5 minutes to obtain the composite emulsion.

[0044] (4) Coat the composite emulsion evenly on the wrapping paper, and dry at 30°C, 60°C, 90°C and 120°C.

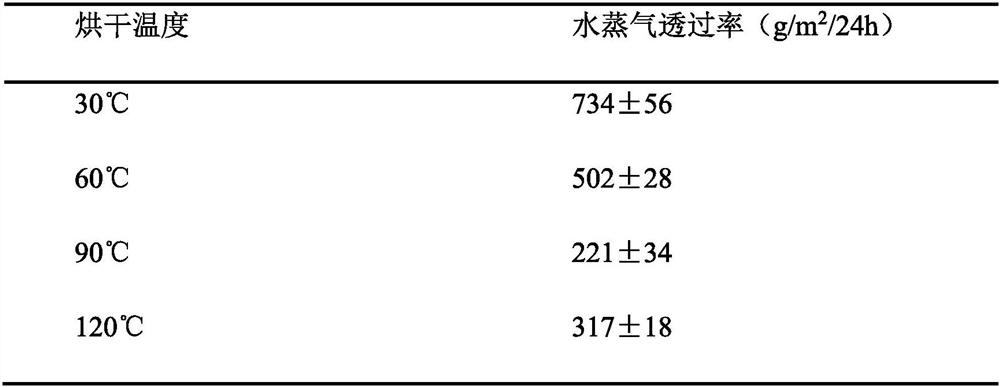

[0045] The water vapor transmission rate test was carried out on the coated paper at different drying temperatures, and the results are shown in the table below:

[0046]

[0047] It can be seen from the results that when the emulsion coating is dried at 90°C, the water vapor barrier property of the coated paper is the strongest.

Embodiment 3

[0049] (1) Take by weighing 4.8g of chitosan in a beaker, add 240mL of 2% acetic acid solution, then add 0.5g of glycerin, stir to make a concentration of 2wt% chitosan solution.

[0050] (2) Add 3 g of palm wax (melting point 85° C.), 0.3 g of Tween 80 and 0.15 g of Span 80 into the chitosan solution, and stir and emulsify at 90° C. for 2 hours at a stirring speed of 1200 rpm.

[0051] (3) The composite emulsion was homogenized by using a high-shear emulsifier, the shear speed was controlled at 22000 rpm, and the shear time was 3 minutes to obtain the composite emulsion.

[0052](4) After the composite emulsion is cooled to room temperature, soak the blank paper in the composite emulsion for 1 min to ensure that the paper sample fully absorbs the emulsion.

[0053] (5) The impregnated papers were divided into two groups, one group was dried at room temperature, and the other group was dried at 100°C.

[0054] The water vapor transmission rate test was carried out on two grou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com