Rosin modified phenolic resin with good heat resistance and preparation process thereof

A technology for modifying phenolic resin and rosin, which is applied in the field of rosin-modified phenolic resin and its preparation, can solve problems such as the need to improve mechanical properties, poor heat resistance, etc., so as to improve high temperature resistance and thermal stability, improve quality and The effect of improving quality and heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

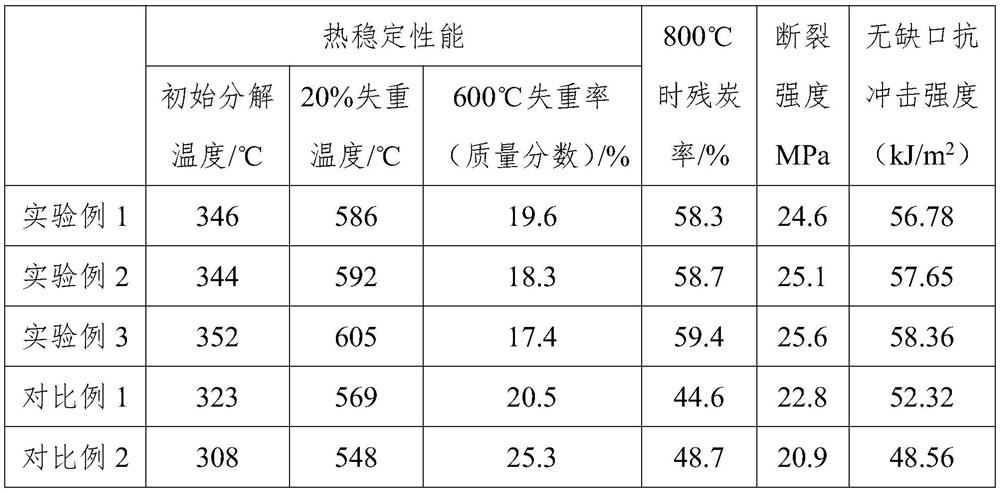

Examples

Embodiment 1

[0027] A rosin-modified phenolic resin with good heat resistance, consisting of phenolic resin microspheres and rosin whose mass is 1.2 times its mass, pentaerythritol with a mass of 5% of rosin, 7% neopentyl glycol, and an appropriate amount of modified serpentine Composition of stone powder.

[0028] The preparation method of phenolic resin microsphere comprises the following steps:

[0029] Weigh phenolic resin, diisopropyl azodicarboxylate, octylphenol polyoxyethylene ether and acetone respectively according to the weight ratio of 1:0.04:0.13:2; after ultrasonic stirring for 30min, let it stand at 35°C for 20h , the gained is recorded as the mixed component; then dropwise add dihydroxy polydimethylsiloxane whose volume fraction is 0.2% to the mixed component while stirring at a rate of 30 drops / min; after the addition is completed, continue Mechanically stir the obtained mixture for 10 minutes; then cool it to room temperature, collect the spherical particles floating on ...

Embodiment 2

[0044] A rosin-modified phenolic resin with good heat resistance, consisting of phenolic resin microspheres, rosin whose mass is 2.5 times its mass, pentaerythritol with a mass of 6% of rosin, 8% neopentyl glycol, and an appropriate amount of modified serpentine Composition of stone powder.

[0045] The preparation method of phenolic resin microsphere comprises the following steps:

[0046] Weigh phenolic resin, diisopropyl azodicarboxylate, octylphenol polyoxyethylene ether and acetone according to the weight ratio of 1:0.05:0.15:3; after ultrasonic stirring for 35 minutes, let it stand at 40°C for 25 hours , the gained is recorded as the mixed component; then dropwise add dihydroxypolydimethylsiloxane whose volume fraction is 0.4% to the mixed component while stirring at a rate of 35 drops / min; after the addition is completed, continue Mechanically stir the resulting mixture for 15 minutes; then cool it to room temperature, collect the spherical particles floating on the li...

Embodiment 3

[0061] A rosin-modified phenolic resin with good heat resistance, consisting of phenolic resin microspheres and rosin whose mass is 3.5 times its mass, pentaerythritol with a mass of 8% of rosin, 10% neopentyl glycol and an appropriate amount of modified serpentine Composition of stone powder.

[0062] The preparation method of phenolic resin microsphere comprises the following steps:

[0063] Weigh phenolic resin, diisopropyl azodicarboxylate, octylphenol polyoxyethylene ether and acetone respectively according to the weight ratio of 1:0.06:0.16:5; after ultrasonic stirring for 40min, let it stand at 50°C for 30h , the gained is recorded as the mixed component; then dropwise add dihydroxypolydimethylsiloxane whose volume fraction is 0.5% to the mixed component while stirring at a rate of 40 drops / min; after the addition is completed, continue Mechanically stir the obtained mixture for 20 minutes; then cool it to room temperature, collect the spherical particles floating on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com