Flame-retardant low-smoke halogen-free silane-free crosslinked polyethylene cable material and preparation method thereof

A technology of cross-linked polyethylene and low-density polyethylene, applied in the direction of circuits, electrical components, plastic/resin/wax insulators, etc., can solve environmental pollution, easy carbonization, cable mechanical properties, volume resistivity and low temperature resistance, etc. drop and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

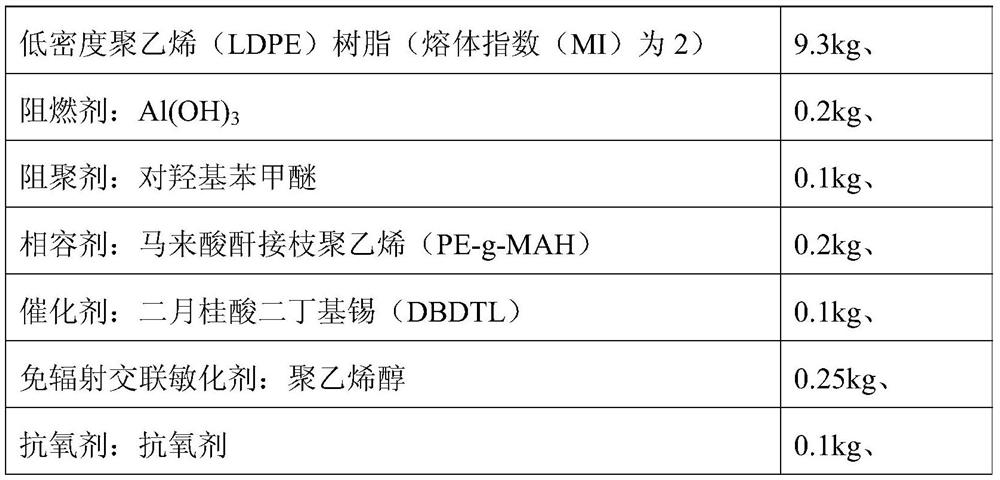

Embodiment 1

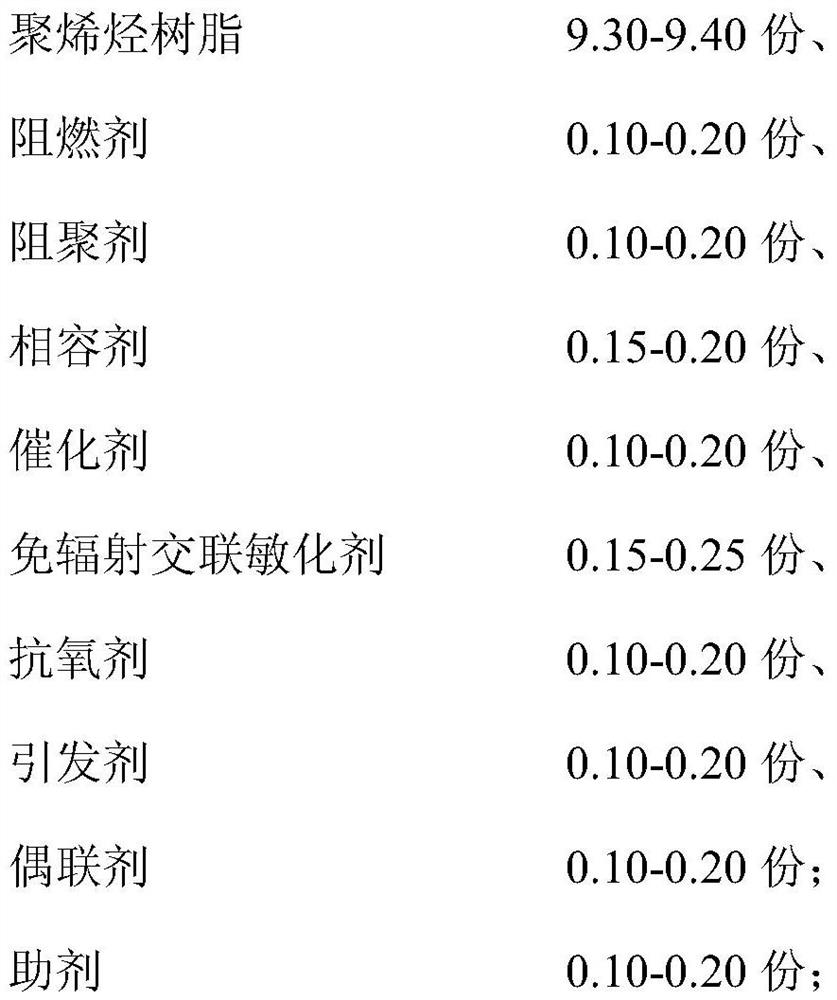

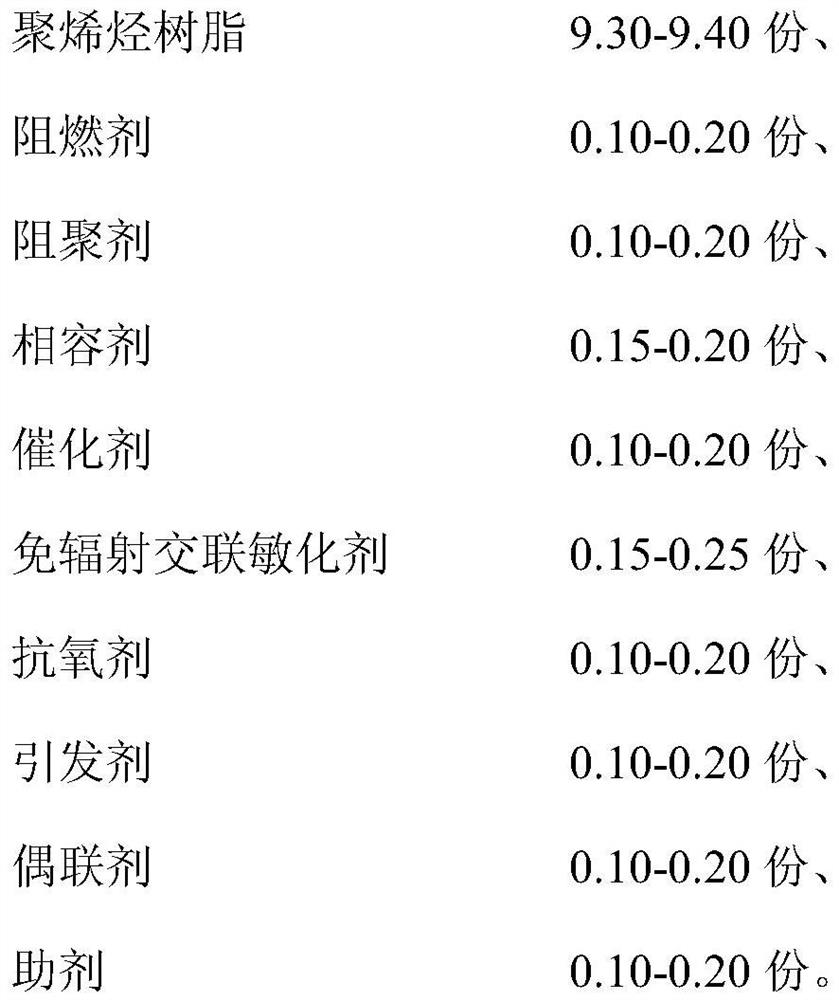

[0029] Flame-retardant low-smoke, halogen-free, silane-free XLPE cable compound, made of the following raw materials in parts by weight:

[0030]

[0031]

Embodiment 2

[0033] Flame-retardant low-smoke, halogen-free, silane-free XLPE cable compound, made of the following raw materials in parts by weight:

[0034] Linear Low Density Polyethylene (LLDPE) 9.4kg, Flame retardant: Al(OH) 3

Embodiment 3

[0036] Flame-retardant low-smoke, halogen-free, silane-free XLPE cable compound, made of the following raw materials in parts by weight:

[0037]

[0038]

[0039] The preparation method of the flame-retardant low-smoke, halogen-free, silane-free cross-linked polyethylene cable material described in Examples 1-3 comprises the following steps:

[0040] 1) compound flame retardant, polymerization inhibitor, compatibilizer and catalyst together according to the formula quantity, and obtain ingredient A through mixing, granulating, cooling and packaging;

[0041] 2) The antioxidant, initiator, and coupling agent are compounded together according to the formula quantity, and ingredients B are obtained by mixing, granulating, cooling, and packaging;

[0042] 3) Compound polyolefin resin, radiation-free cross-linking sensitizer, auxiliary agent, ingredient A, and ingredient B according to the formula amount, mix them uniformly, transport them to a twin-screw extruder, and process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com