High-density fermentation culture medium for lycopene-producing saccharomyces cerevisiae

A technology of high-density fermentation and Saccharomyces cerevisiae, which is applied in the field of high-density fermentation medium and can solve problems such as optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

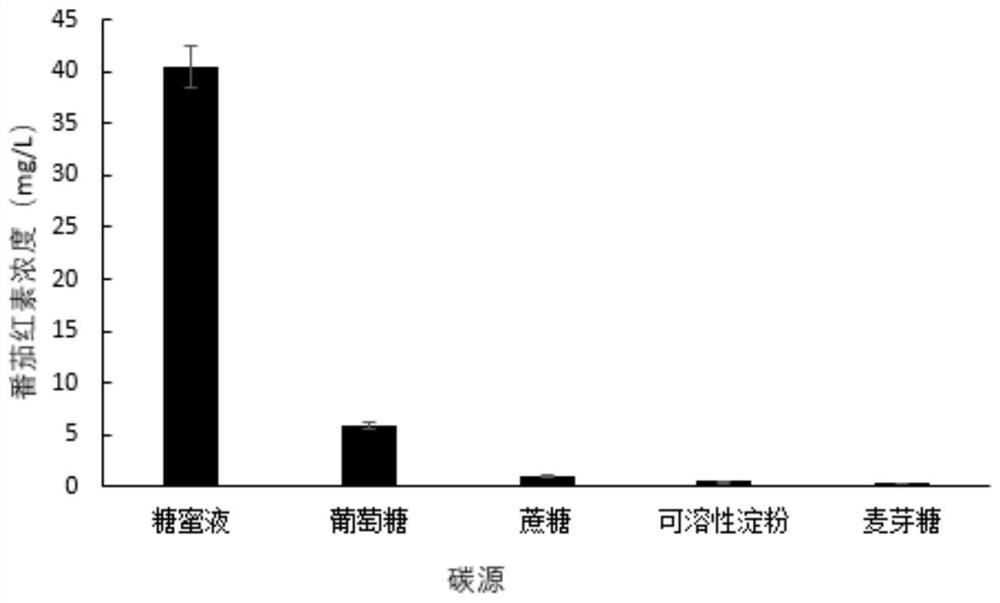

[0031] Embodiment 1: Comparison of single factor test results of optimum carbon source and optimum nitrogen source shake flask fermentation in the culture medium

[0032] Determination of the most suitable carbon source

[0033] Basic fermentation medium 1 composition: carbon source 2%, peptone 2%, KH 2 PO 4 0.1%, pH7.0. Cane molasses liquid, glucose, sucrose, soluble starch or maltose were added as carbon sources (2%) to the basal fermentation medium 1 respectively.

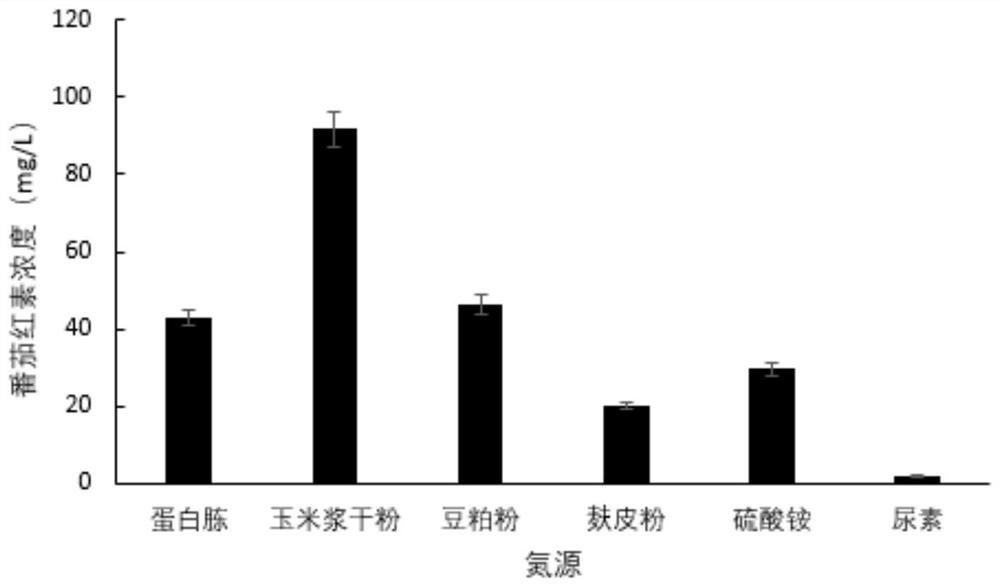

[0034] Determination of optimal nitrogen source

[0035] Composition of fermentation medium 2: sugarcane molasses liquid 2%, nitrogen source 2%, KH 2 PO 4 0.1%, pH7.0. An appropriate amount of nitrogen source was added on the basis of the selected optimum carbon source (sugarcane molasses liquid). Peptone, corn steep liquor dry powder, soybean meal powder, bran powder, ammonium sulfate or urea were added to fermentation medium 2 as nitrogen source (2%) instead.

[0036] The preparation method of the cu...

Embodiment 2

[0044] Embodiment 2: Configuration of fermentation medium 1 and comparison of fermentation results

[0045] Saccharomyces cerevisiae high-density fermentation medium composition: according to the ratio per liter, sugarcane molasses liquid 35g / L, corn steep liquor dry powder 20g / L, potassium dihydrogen phosphate 1.5g / L, MgSO 4 . 7H 2 O 3g / L, potassium sulfate 5g / L.

[0046] The preparation method of the culture medium is as follows: mix the above ingredients evenly, dissolve them with distilled water, put the prepared culture medium into a fermenter, stir evenly, and sterilize at 115° C. for 20 minutes under high temperature and high pressure.

[0047] In order to achieve the best effect of the medium, when using the above-mentioned Saccharomyces cerevisiae high-density fermentation medium to ferment Saccharomyces cerevisiae, the fermentation process is as follows:

[0048] The main operating steps of the high-density fermentation of the present embodiment are as follows:

...

Embodiment 3

[0063] Embodiment 3: the preparation of fermentation medium 2 and the comparison of fermentation result

[0064] Saccharomyces cerevisiae high-density fermentation medium composition: according to the ratio per liter, sugarcane molasses liquid 30g / L, corn steep liquor powder 20g / L, potassium dihydrogen phosphate 1.5g / L, MgSO 4 . 7H 2 O 3g / L, potassium sulfate 5g / L.

[0065] The preparation method of the culture medium is as follows: mix the above ingredients evenly, dissolve them with distilled water, put the prepared culture medium into a fermenter, stir evenly, and sterilize at 115° C. for 20 minutes under high temperature and high pressure.

[0066] In order to achieve the best effect of the medium, when using the above-mentioned Saccharomyces cerevisiae high-density fermentation medium to ferment Saccharomyces cerevisiae, the fermentation process is as follows:

[0067] The main operating steps of the high-density fermentation of the present embodiment are as follows: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com