Enzyme preparation adding process for promoting fermentation of starch grain

A kind of grain and additive technology, applied in the direction of fermentation, biofuel, etc., can solve the problems of high catalytic efficiency of different enzyme preparations, and achieve the effect of improving the efficiency of enzymatic reaction, reducing the content of residual sugar, and improving the efficiency of concentration and drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

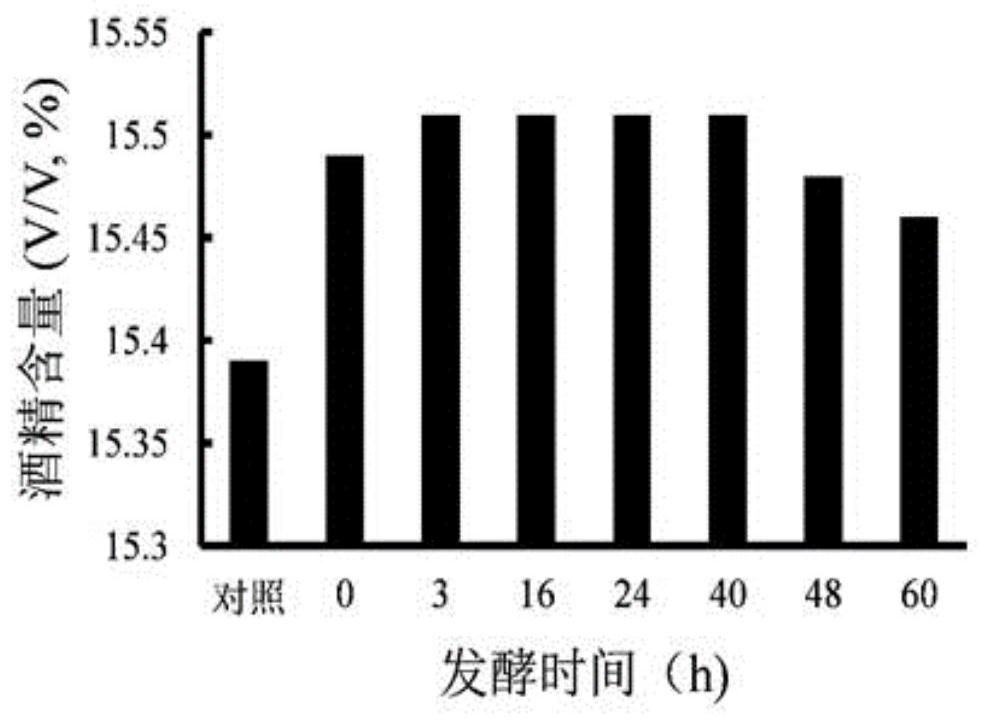

[0072] Embodiment 1 adds the influence of α-glucosidase on alcoholic fermentation at different times

[0073] 1. Experimental method of the present invention

[0074] Raw material liquefaction: Take a certain amount of fully ground corn flour (purchased from an alcohol factory A) to prepare a feed liquid with a feed water ratio of 1:2.0-3.0. After the preparation is completed, the pH is adjusted to be about 4.5-6.0, and an appropriate amount of high-temperature amylase (such as X5, the addition amount is 10~100U / g DS) for liquefaction. Liquefaction conditions: temperature 95°C, time 120min.

[0075] Yeast expansion: Take 1g of dry yeast (purchased from Angel Yeast Co., Ltd., Angel Super Saccharomyces cerevisiae) into a 50ml centrifuge tube, add 9g of distilled water, mix well, place in a 38°C water bath, and activate for 60min.

[0076] Fermentation: Lower the liquefied feed solution to room temperature in time and adjust the pH to 4.3, distribute it evenly into shake flas...

Embodiment 2

[0113] Embodiment 2 adds the influence of α-glucosidase on alcoholic fermentation at different times of fermentation

[0114] With reference to the experimental method of the present invention of embodiment 1, matched group and analytical method, after subpackaging shake flask, add 2U / g DSα-glucosidase (amino acid The sequence is SEQ ID NO.2, and the nucleotide sequence encoding the amino acid is SEQ ID NO.1). Replace cornmeal with cornmeal purchased from an alcohol factory B

[0115] Experimental results:

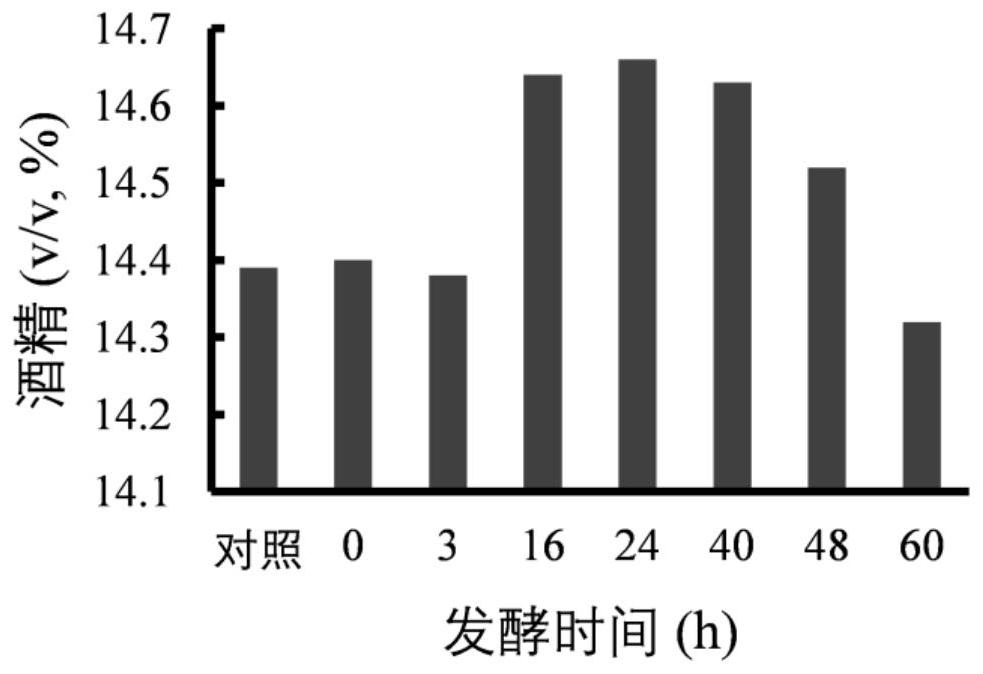

[0116] Add 2U / g DSα-glucosidase at 0h, 3h, 16h, 24h, 40h, 48h and 60h of alcoholic fermentation. After the fermentation is finished, the components in the fermentation broth are analyzed by high-performance liquid chromatography, and the residual reducing sugar, filtered total sugar and residual total sugar of the mash are detected. Result is as follows table 3, table 4 and figure 1 shown. According to the analysis of experimental results, adding 2U / g DSα-glucosidase ...

Embodiment 3

[0123] Example 3 Effect of adding the α-glucosidase of Amano Enzyme Co., Ltd. on alcoholic fermentation at different times of fermentation

[0124] With reference to the experimental method of the present invention, control group and analytical method of embodiment 1, the enzyme that adds after the packing shake flask is changed into the α-glucosidase (trade name: transglucosidase of 2U / g DS Amano Enzyme Products Co., Ltd.) L, "Amano").

[0125] The corn flour is replaced with corn flour purchased from an alcohol factory B.

[0126] Experimental results:

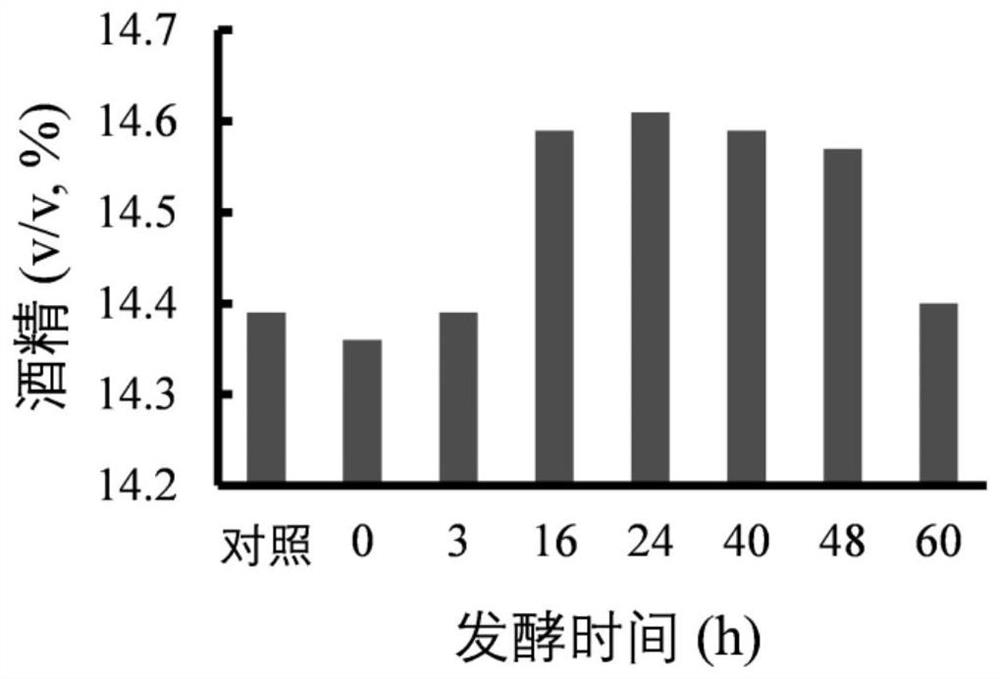

[0127] Add 2U / g DSα-glucosidase from Amano Enzyme Co., Ltd. at 0h, 3h, 16h, 24h, 40h, 48h and 60h of alcoholic fermentation. After the fermentation is finished, the components in the fermentation broth are analyzed by high-performance liquid chromatography, and the residual reducing sugar, filtered total sugar and residual total sugar of the mash are detected. Result is as follows table 5, table 6 and figure 2 shown. A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com