High-strength heat-resistant aluminum alloy powder for 3D printing and preparation method thereof

A 3D printing and aluminum alloy technology, applied in the field of 3D printing, can solve problems such as cracking, mechanical property degradation, and component failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

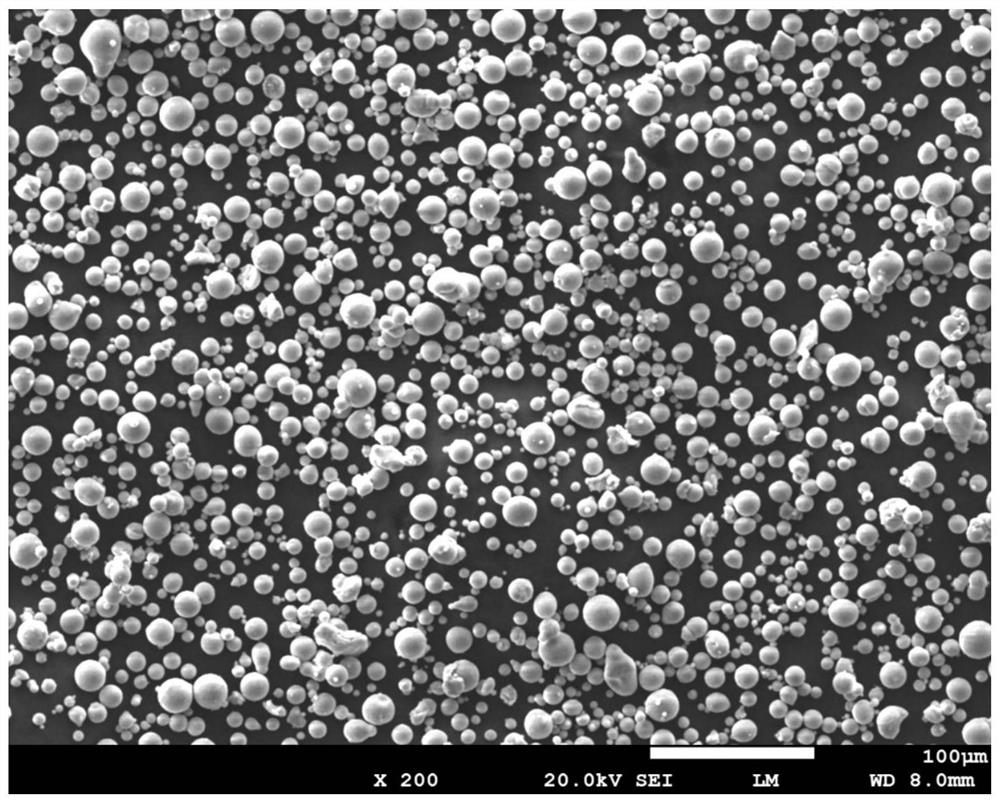

Image

Examples

Embodiment 1

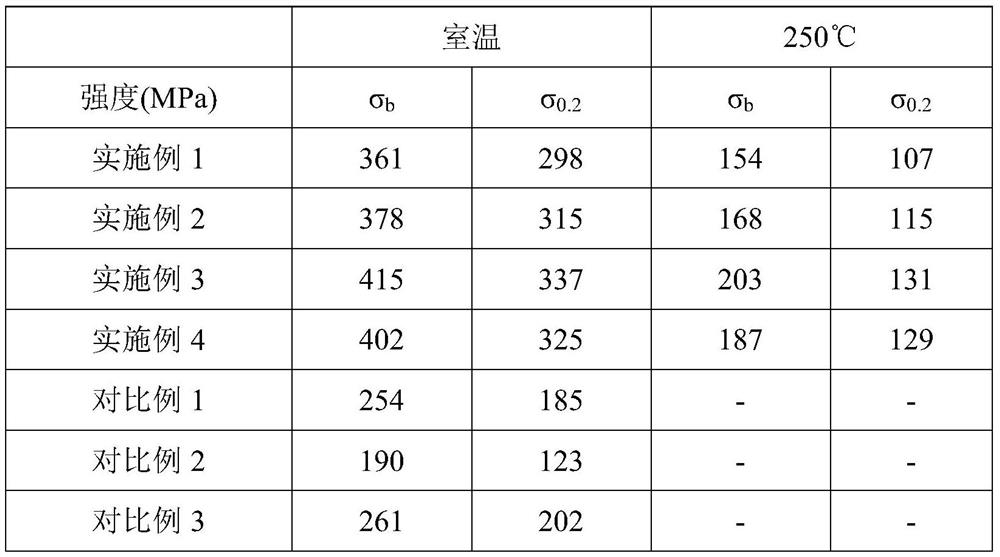

[0034] This embodiment provides a high-strength heat-resistant aluminum alloy powder for 3D printing, which consists of the following components and mass percentages: Fe 8.0%, V 1.0%, Si 1.5%, Mn 0.6%, Mg 1.8%, Cu 1.8%, Ti 0.05% %, Zr 0.15%, Sr 0.01%, La 0.05%, Sc 0.05%, and the rest are Al and unavoidable impurities. The preparation method comprises the following steps:

[0035] (1) Using the master alloy of pure aluminum, pure magnesium and aluminum as raw material, carry out batching according to the above-mentioned mass percentage according to the alloy composition;

[0036] (2) Put the raw materials in step (1) into an intermediate frequency induction graphite furnace, in which the magnesium needs to be wrapped with aluminum foil and pressed at the bottom, and the prepared raw materials are heated and melted under a protective atmosphere at a melting temperature of 700 ° C, kept for 5 minutes, and then Pour into molds to cool;

[0037] (3) Select qualified aluminum allo...

Embodiment 2

[0041] This embodiment provides a high-strength heat-resistant aluminum alloy powder for 3D printing, which is composed of the following components and mass percentages: Fe 9.0%, V 1.1%, Si 1.7%, Mn 0.7%, Mg 1.9%, Cu 1.9%, Ti 0.1 %, Zr 0.2%, Sr0.02%, La 0.12%, Er 0.08%, and the rest are Al and unavoidable impurities. The preparation method comprises the following steps:

[0042] (1) Using the master alloy of pure aluminum, pure magnesium and aluminum as raw material, carry out batching according to the above-mentioned mass percentage according to the alloy composition;

[0043] (2) Put the raw materials in step (1) into an intermediate frequency induction graphite furnace, in which the magnesium needs to be wrapped with aluminum foil and pressed at the bottom, and the prepared raw materials are heated and melted under a protective atmosphere at a melting temperature of 750°C and kept for 5 minutes. Then pour into the mold to cool;

[0044] (3) Select qualified aluminum alloy...

Embodiment 3

[0048] This embodiment provides a high-strength heat-resistant aluminum alloy powder for 3D printing, which is composed of the following components and mass percentages: Fe 10.0%, V 1.2%, Si 1.9%, Mn 0.8%, Mg 2.0%, Cu 2.0%, Ti 0.15% %, Zr 0.25%, Sr 0.025%, Ce 0.15%, Sc 0.15%, and the rest are Al and unavoidable impurities. The preparation method comprises the following steps:

[0049] (1) Using the master alloy of pure aluminum, pure magnesium and aluminum as raw material, carry out batching according to the above-mentioned mass percentage according to the alloy composition;

[0050] (2) Put the raw materials in step (1) into an intermediate frequency induction graphite furnace, in which the magnesium needs to be wrapped with aluminum foil and pressed at the bottom, and the prepared raw materials are heated and melted under a protective atmosphere at a melting temperature of 800°C and kept for 10 minutes. Then pour into the mold to cool;

[0051] (3) Select qualified aluminu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com