Preparation method and application of hydrogen evolution catalytic material Pt-CoP

A pt-cop, sodium borohydride technology, applied in chemical instruments and methods, inorganic chemistry, cobalt compounds, etc., can solve problems such as poor catalytic performance, increase electrochemical active surface area, facilitate contact, excellent hydrogen Effects of precipitation performance and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

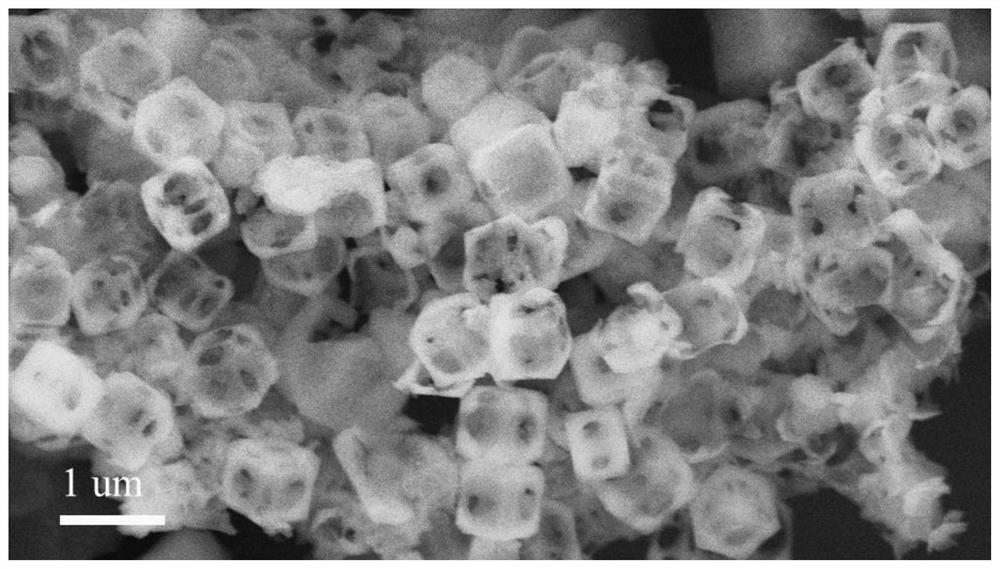

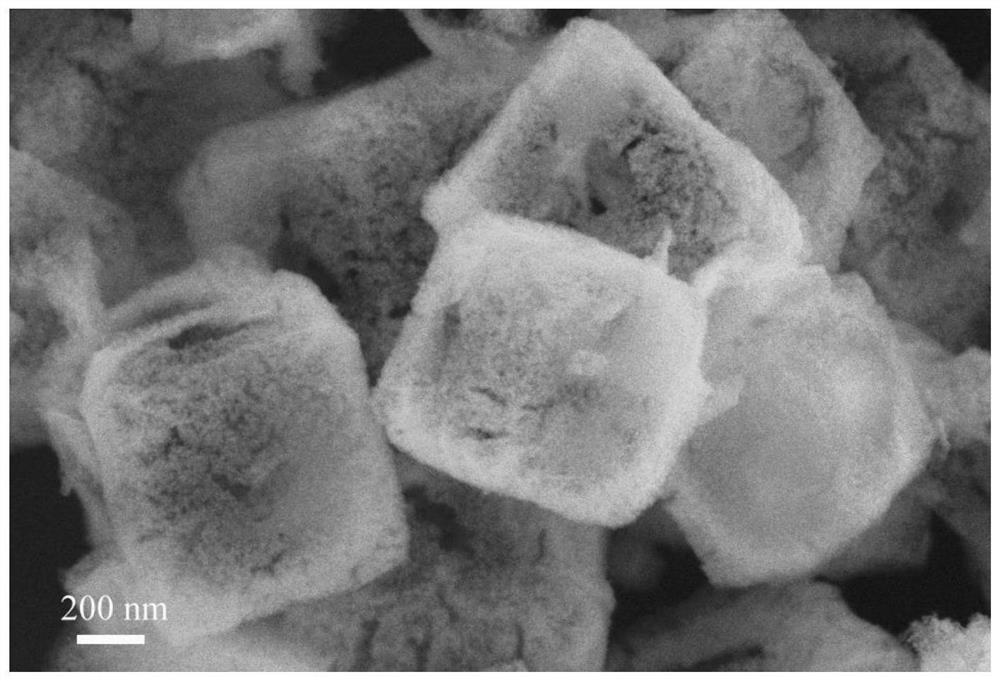

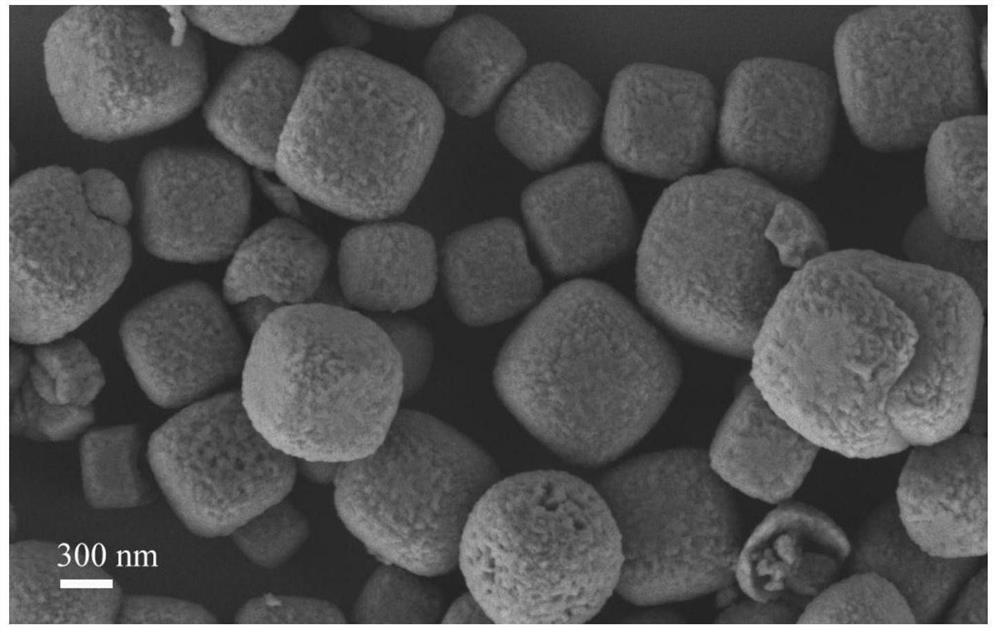

Image

Examples

Embodiment 1

[0039] A preparation method of hydrogen evolution electrocatalytic material Pt-CoP is as follows:

[0040] (1) Pour 7.5mL of aqueous solution dispersed with 75mg of polyvinylpyrrolidone and 65mg of squaraine into 2.5mL of methanol solution of 141.2mg of cobalt nitrate, sonicate for 1min, let stand for 72h, wash with water three times, and centrifuge at 8000rpm for 5min , freeze-dried to obtain a pink powder;

[0041] (2) Place the pink powder prepared in (1) in argon, then raise the temperature to 400°C at 1°C / min, and keep it warm for 2h to obtain the precursor powder;

[0042] (3) Take 0.05g of the precursor powder and 0.8g of sodium hypophosphite prepared in (2) and place them in argon, and place the precursor powder at the gas outlet of the tube furnace, below the sodium hypophosphite. Then the temperature was raised to 350°C at 5°C / min, and kept for 2 hours to obtain a black powder CoP;

[0043] (4) Take 25 mg of the black powder prepared in (3) and disperse it in 2.5 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com