A kind of preparation method of potassium permanganate

A potassium permanganate and carbonate technology, applied in manganate/permanganate, chemical instruments and methods, manganese compounds, etc., can solve the problems of low product purity, poor production environment, long production cycle, etc. Achieve the effect of high atomic utilization, easy control and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

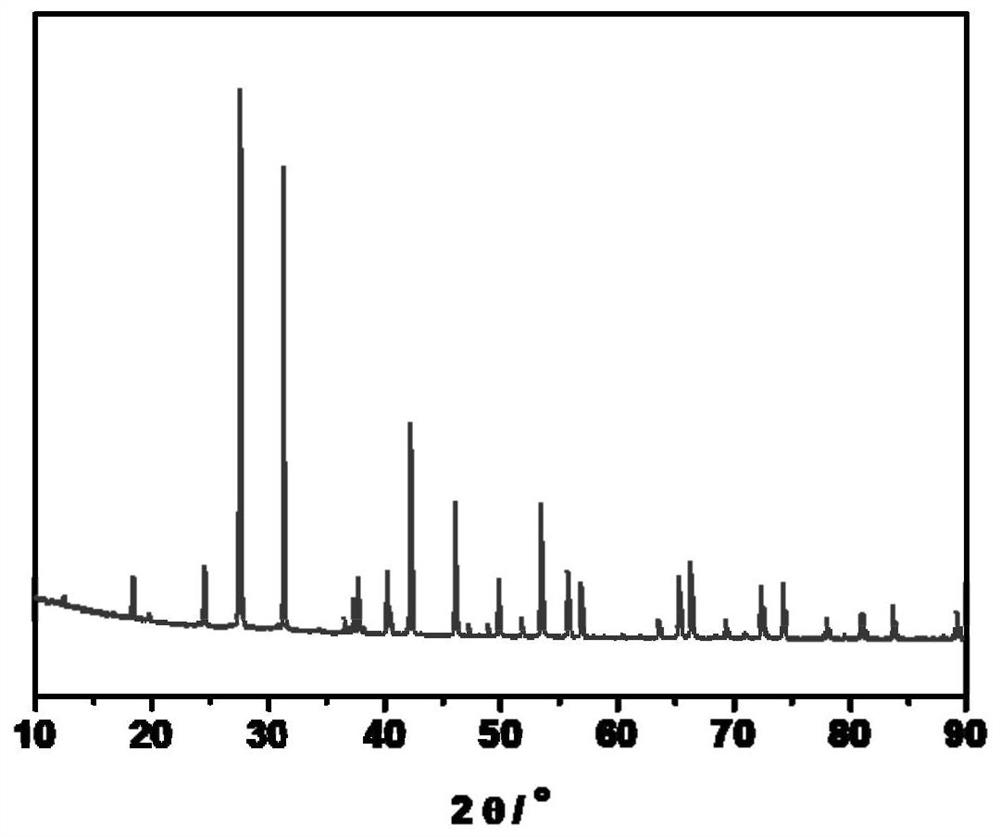

[0037] According to the technical scheme of the present invention, the solid-phase method synthesizes novel oxide Ba 3 mn 2 o 8 Primary powder, mix 59.2g of barium carbonate and 17.4g of manganese dioxide and sinter at 900°C in air for 24 hours to obtain Ba with trigonal structure 3 mn 2 o 8 Solid powder, X-ray diffraction results are as follows figure 1 shown. Ba 3 mn 2 o 8 diffraction peaks.

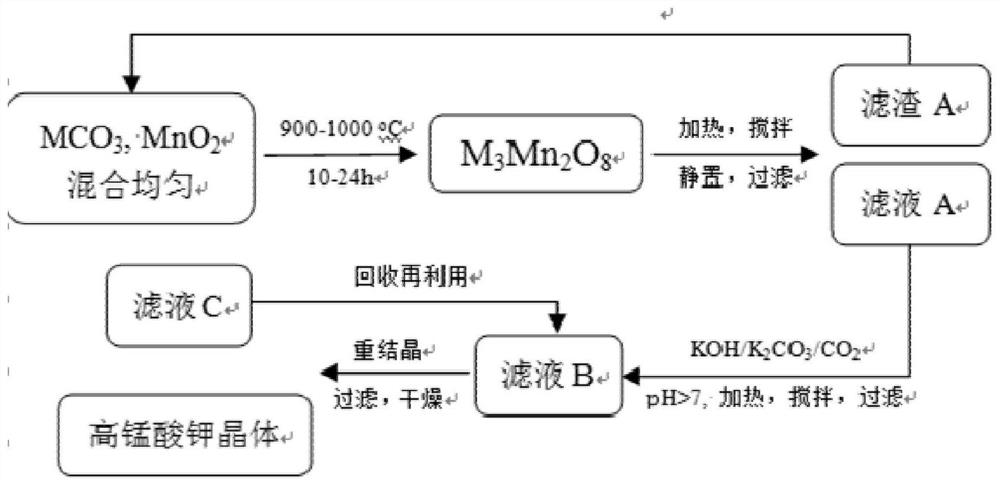

[0038] The above obtained novel oxide 5gBa 3 mn 2 o 8 Put directly into deionized water, heat and stir, control the temperature of the suspension to 50°C, and stir at a speed of 200r / min, the suspension will turn purple and the color will continue to deepen. After 2h, let it stand for 1h to settle the solid particles, filter the supernatant, add 2g of KOH solid, and blow in CO with a flow rate of 30mL / min. 2 , control the pH value to be greater than 7 to completely precipitate Ba ions, filter to obtain a purple-red supernatant, slowly heat and stir to crystallize, and obt...

Embodiment 2

[0040] According to the technical scheme of the present invention, the solid-phase method synthesizes novel oxide Mg 3 mn 2 o 8 , Ca 3 mn 2 o 8 、Sr 3 mn 2 o 8 、Ba 3 mn 2 o 8 The primary powder was calcined in air at 1050°C, 1000°C, 950°C, and 900°C for 24 hours respectively. Take 5g of each of the four oxides into the same amount of deionized water, heat and stir, control the temperature of the suspension at 50°C, and stir at a speed of 200r / min, the suspension turns purple and the color continues to deepen. After 2h, let it stand for 1h to settle the solid particles, filter the supernatant, add 2g KOH solid each, and blow in CO with a flow rate of 30mL / min. 2 , control the pH value greater than 7 to completely precipitate Mg, Ca, Sr, and Ba ions, and filter to obtain a purple supernatant. Slowly heated and stirred for crystallization, and purple-red potassium permanganate crystals were obtained, and the detected purity was 63%, 85%, 92%, and 95%, respectively. Th...

Embodiment 3

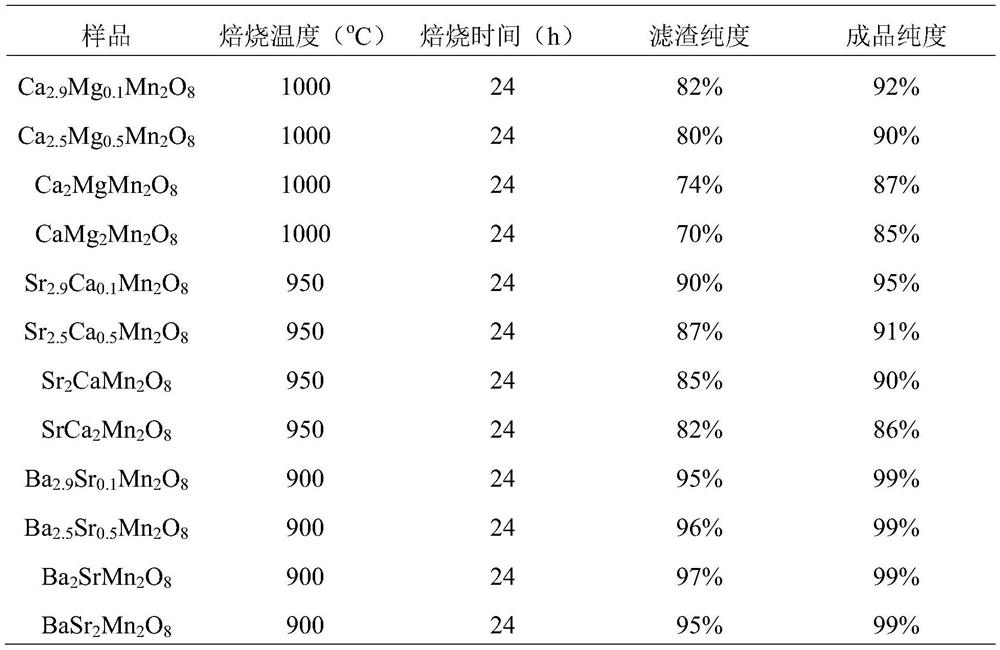

[0042] According to the technical scheme of the present invention, novel oxide Ca is synthesized by solid-phase method 3-x Mg x mn 2 o 8 ,Sr 3-x Ca x mn 2 o 8 、Ba 3- x Sr x mn 2 o 8 (x=0.1, 0.5, 1, 2) primary powder, adjust the calcination temperature and holding time, and sinter at high temperature in air to obtain solid powder. The preparation conditions are shown in Table 1. Take 5g of each of the 12 kinds of oxides and put them into the same amount of deionized water respectively, and put the four kinds of oxides of the same amount into the same amount of deionized water respectively, heat and stir, control the temperature of the suspension to 50°C, and the stirring speed to 200r / min, The suspension turned purple and deepened in color. After 2h, let it stand for 1h to settle the solid particles, filter the supernatant, add 2g of KOH solid, and blow in CO with a flow rate of 30mL / min. 2 , control the pH value to be greater than 7 to completely precipitate the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com