Dairy cow breeding manure treatment process

A treatment process and manure technology, which is applied in the field of cow breeding manure treatment process to achieve the effects of ensuring normal operation, reducing energy consumption and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

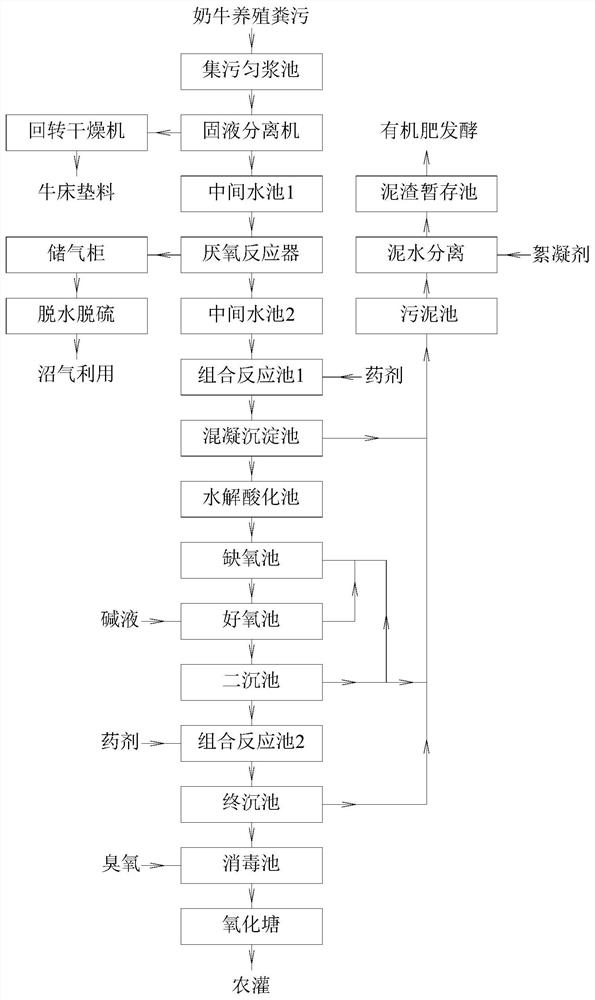

[0050] A kind of dairy cow breeding manure treatment process provided in this embodiment, for dairy farms that use organic matter such as rice husks and sawdust as bedding materials for cow beds, the process flow chart is as follows figure 1 As shown, it specifically includes the following steps:

[0051] Step 1: The manure in the cowshed of the dairy farm enters the sump, and the homogenization of water quality and water quantity is realized in the sump;

[0052] Step 2: The feces in the sump are pumped into the solid-liquid separator through the sump pump to separate the large particles and long-fiber solids in the feces. The solids separated by the solid-liquid separator fall into the dung temporary storage tank. The waste water after solid-liquid separation flows into the intermediate pool 1 by itself;

[0053] Step 3: The waste water in the middle pool 1 is pumped into the anaerobic reactor through the lift pump of the middle pool 1 to carry out anaerobic reaction, and t...

Embodiment 2

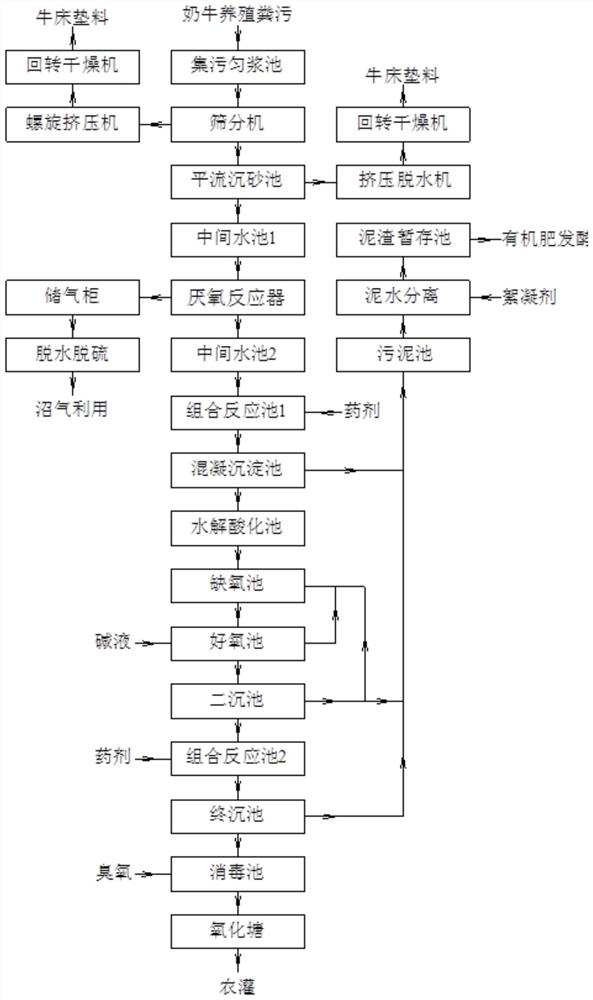

[0080] This embodiment provides a dairy cow breeding manure treatment process. For dairy farms that use organic and inorganic mixtures such as rice husk, sawdust, and quartz sand as bedding materials for cow beds, the process flow chart is as follows figure 2 As shown, it specifically includes the following steps:

[0081] Step 1: The cow manure in the cowshed of the farm enters the sump, and the water quality and water quantity are homogenized in the sump;

[0082] Step 2: The feces in the sump are conveyed through the sump into the screening machine to separate the large particles and long-fiber solids in the feces. The solids separated by the screening machine will first fall into the extrusion dehydrator for further dehydration, and then fall into the Temporary dregs storage tank, the solids in the dung dregs temporary storage tank are transported to the rotary dryer for drying, and kill pathogenic microorganisms, and then reuse them as bedding materials for cattle beddin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com