Hollow microsphere and preparation method thereof

A microsphere and hollow technology, applied in the field of hollow microspheres and their preparation, can solve the problems of difficult to control stability, strict requirements for olefinic monomers, complex synthesis methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

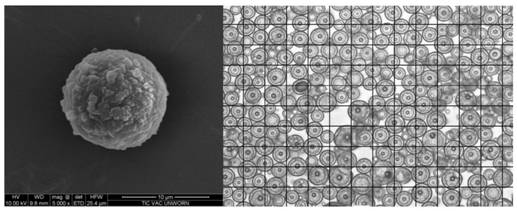

Image

Examples

preparation example Construction

[0025] The embodiment of the present application provides a method for preparing hollow microspheres, comprising the following steps:

[0026] In parts by mass, 0-100 parts of air-tight monomers, 10-100 parts of acrylate monomers, 0-50 parts of amide monomers, 10-100 parts of olefin monomers and 0-10 parts of initiators, Mix 0-10 parts of cross-linking agent and 20-60 parts of core material, stir in an oil phase tank of 0-15Mpa to prepare the oil phase;

[0027] In parts by mass, 100 parts of deionized water, 0.5-10 parts of inorganic dispersant, 0.5-50 parts of inorganic salt, 0.01-5 parts of surfactant, 0.01-5 parts of thickener, and 0.01-5 parts of molecular weight regulator The ratio is added to the water phase tank in sequence, and the water phase is prepared by stirring evenly under normal pressure. The inorganic dispersant is a sol-like solution obtained by adding the cationic salt of the inorganic particles to the anionic salt of the inorganic particles;

[0028] Afte...

Embodiment 1

[0047] Preparation of the water phase: Take 1500 parts of the prepared silver chloride water phase, then add 0.1 part of sodium dodecylsulfonate, stir vigorously to prepare the water phase, and the pH value of the water phase is 7.

[0048] Preparation of oil phase: Take 170 parts of acrylonitrile, 20 parts of methacrylonitrile, 10 parts of methyl methacrylate, 25 parts of pentane, 1 part of azobisisobutyronitrile, and 0.1 part of divinylbenzene to prepare an oil phase. The oil phase can be mixed evenly under the pressure of 0.6Mpa.

[0049] Then mix the oil phase with the water phase, homogenize for 30 minutes under stirring at 10,000 rpm, put the emulsion in a homogenizing tank, and polymerize at a stirring speed of 300 rpm, the polymerization temperature is 60°C, and the polymerization time is 24 hours.

[0050] After the reaction is over, add a defoamer to the kettle, and slowly release the pressure to allow the pentane to escape. Suction filtration, filter cake drying, s...

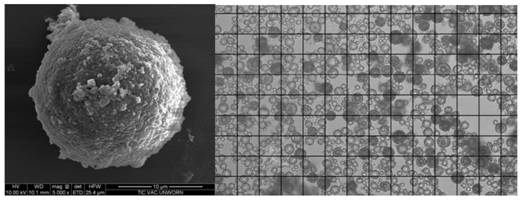

Embodiment 2

[0052] Preparation of the water phase: Take 1500 parts of the prepared magnesium hydroxide water phase, then add 0.1 part of sodium dodecylsulfonate into it, stir vigorously to prepare the water phase, and the pH value of the water phase is 7.

[0053] Preparation of oil phase: Take 170 parts of acrylonitrile, 20 parts of methacrylonitrile, 10 parts of methyl methacrylate, 25 parts of pentane, 1 part of azobisisobutyronitrile and 0.1 part of divinylbenzene to prepare an oil phase. The oil phase can be mixed evenly under the pressure of 10Mpa.

[0054] Mix the oil phase and the water phase in a homogenization tank, homogenize for 30 minutes under stirring at 10,000 rpm, transfer the homogenized emulsion to the reactor, and polymerize at a stirring speed of 300 rpm / min at a polymerization temperature of 50°C and a polymerization time of 24 hours.

[0055] After the reaction was finished, suction filtration and drying of the filter cake resulted in core-containing microspheres wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com