Fluorine-containing polymer with high peeling force and high transparency and its preparation method

A high-transparency, high-peeling technology, applied in the direction of adhesives, etc., can solve the problems of low peeling force and transparency of fluoropolymers, the use of more reaction aids, and low polymerization temperature, so as to broaden the scope of processing and use, improve transparency and distribution uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

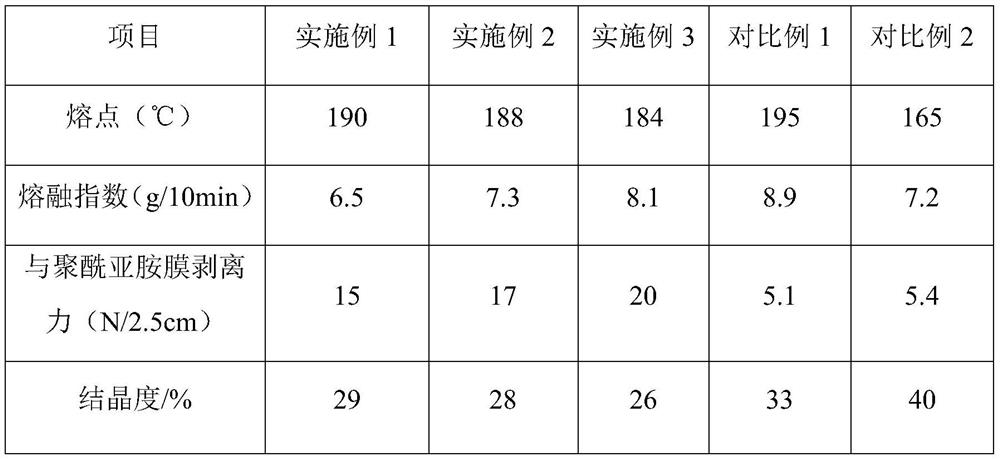

Examples

Embodiment 1

[0031] In a 10L stainless steel polymerization kettle, add 5.5L of deionized water, add 20g of ammonium perfluorooctanoate (40% by mass), treat the oxygen content of the polymerization kettle to be qualified, turn on the polymerization kettle and stir, then add the initial monomer mixture, the initial monomer added The mass of tetrafluoroethylene and hexafluoropropylene in the mixture is 1:2, the temperature is raised to 80 ° C, the constant reaction pressure is 2.5 MPa, 10 mL of 2.5 wt % ammonium persulfate initiator is added, and then continuously added to the polymerization kettle. For the monomer, the mass ratio of ethylene, tetrafluoroethylene and hexafluoropropylene in the gas phase part of the supplementary monomer is 2:9:6, and the total weight is 2kg. During the process of adding additional monomers, 50 mL of 2.5 wt% ammonium persulfate was continuously added to supplement the initiator, and at the same time, the CH prepared with 20 g of ammonium perfluorooctanoate was...

Embodiment 2

[0033]In a 10L stainless steel polymerization kettle, add 5.5L of deionized water, add 20g of ammonium perfluorooctanoate (40% by mass), treat the oxygen content of the polymerization kettle to be qualified, turn on the polymerization kettle and stir, then add the initial monomer mixture, the initial monomer added The mass of tetrafluoroethylene and hexafluoropropylene in the mixture is 1:2, the temperature is raised to 80 ° C, the constant reaction pressure is 2.5 MPa, 10 mL of 2.5 wt % ammonium persulfate initiator is added, and then continuously added to the polymerization kettle. For the monomer, the mass ratio of ethylene, tetrafluoroethylene and hexafluoropropylene in the gas phase part of the supplementary monomer is 2:9:6, and the total weight is 2kg. During the process of adding additional monomers, 50 mL of 2.5 wt% ammonium persulfate was continuously added to supplement the initiator, and at the same time, the CH prepared with 20 g of ammonium perfluorooctanoate was ...

Embodiment 3

[0035] In a 10L stainless steel polymerization kettle, add 5.5L of deionized water, add 20g of ammonium perfluorooctanoate (40% by mass), treat the oxygen content of the polymerization kettle to be qualified, turn on the polymerization kettle and stir, then add the initial monomer mixture, the initial monomer added The mass of tetrafluoroethylene and hexafluoropropylene in the mixture is 1:2, the temperature is raised to 80 ° C, the constant reaction pressure is 2.5 MPa, 10 mL of 2.5 wt % ammonium persulfate initiator is added, and then continuously added to the polymerization kettle. For the monomer, the mass ratio of ethylene, tetrafluoroethylene and hexafluoropropylene in the gas phase part of the supplementary monomer is 2:9:6, and the total weight is 2kg. During the process of adding additional monomers, 50 mL of 2.5 wt% ammonium persulfate was continuously added to supplement the initiator, and at the same time, the CF prepared with 20 g of ammonium perfluorooctanoate was...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com