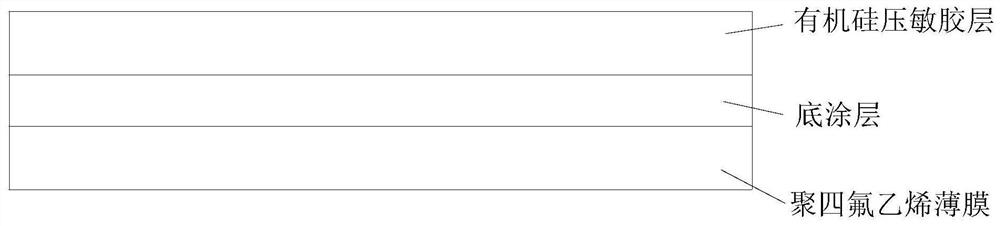

Manufacturing method of polytetrafluoroethylene organic silicon pressure-sensitive adhesive tape

A technology of polytetrafluoroethylene and silicon pressure-sensitive tape, which is applied in the direction of pressure-sensitive film/sheet, adhesive, film/sheet-shaped adhesive, etc. It can solve problems such as non-compliance with environmental protection requirements, darkening of PTFE surface, pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

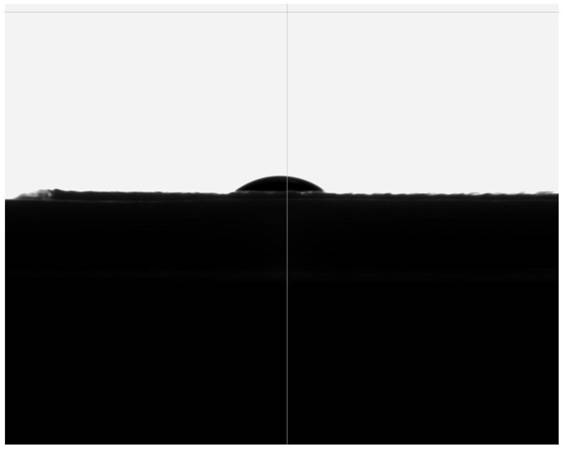

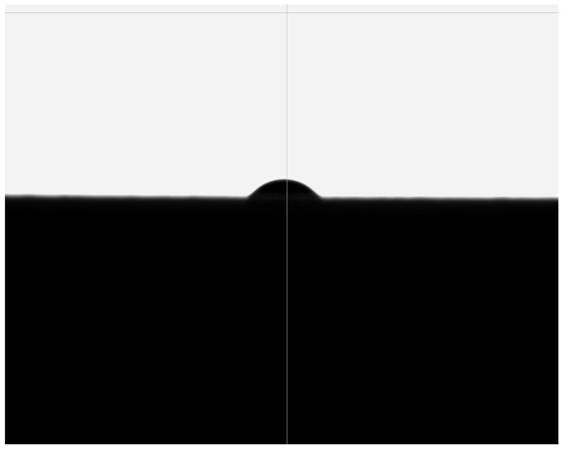

Embodiment 1

[0026] (1) Put the polytetrafluoroethylene film roll into the plasma processing equipment, adjust the distance between the film and the electrode plate to 10CM, close the chamber door of the equipment, and start the vacuum pump. After being vacuumed to 30PA, low-temperature and low-pressure plasma is used to impact the surface of the polytetrafluoroethylene film for surface modification. The processing parameters are: by adjusting the rewinding and unwinding speed, the processing time is controlled at 4 minutes, the processing power is 10KW, the temperature is 25°C, the working gases used are nitrogen and hydrogen, the gas flow rate of nitrogen gas is 200 sccm, the gas flow rate of hydrogen gas is 150 sccm, and the working pressure is 50Pa. After the treatment, the water contact angle of the polytetrafluoroethylene film was tested with a contact angle meter. Such as figure 2 , 3 As shown, after detection, the contact angle after plasma treatment according to this treatment...

Embodiment 2

[0030] (1) Put the polytetrafluoroethylene film roll into the plasma processing equipment, adjust the distance between the film and the electrode plate to 5CM, close the chamber door of the equipment, and start the vacuum pump. After being vacuumed to 30PA, low-temperature and low-pressure plasma is used to impact the surface of the polytetrafluoroethylene film for surface modification. The processing parameters are: by adjusting the winding and unwinding speed, the processing time is controlled at 0.5min, the processing power is 20KW, the temperature is 40°C, the working gases used are nitrogen and hydrogen, the gas flow rate of nitrogen gas is 100 sccm, and the gas flow rate of hydrogen gas is 800 sccm. The air pressure is 250Pa. After the treatment, the water contact angle of the polytetrafluoroethylene film was tested with a contact angle meter. After testing, the contact angle after plasma treatment according to this treatment parameter is 85.8°. After standing for one ...

Embodiment 3

[0034] (1) Put the polytetrafluoroethylene film roll into the plasma processing equipment, adjust the distance between the film and the electrode plate to 30CM, close the chamber door of the equipment, and start the vacuum pump. After being vacuumed to 30PA, low-temperature and low-pressure plasma is used to impact the surface of the polytetrafluoroethylene film for surface modification. The processing parameters are: by adjusting the winding and unwinding speed, the processing time is controlled at 8 minutes, the processing power is 1KW, the temperature is 0°C, the working gases used are nitrogen and hydrogen, the gas flow rate of nitrogen gas is 800 sccm, the gas flow rate of hydrogen gas is 50 sccm, and the working pressure is 5Pa. After the treatment, the water contact angle of the polytetrafluoroethylene film was tested with a contact angle meter. After testing, the contact angle after plasma treatment according to this treatment parameter is 65.8°. After standing for o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com