A kind of manganese dioxide composite nitrogen-sulfur double-doped porous carbon and its preparation method and application

A manganese dioxide, porous carbon technology, applied in the manufacture of hybrid/electric double-layer capacitors, hybrid capacitor electrodes, etc., can solve the problems of limited practical application and lower energy density than batteries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

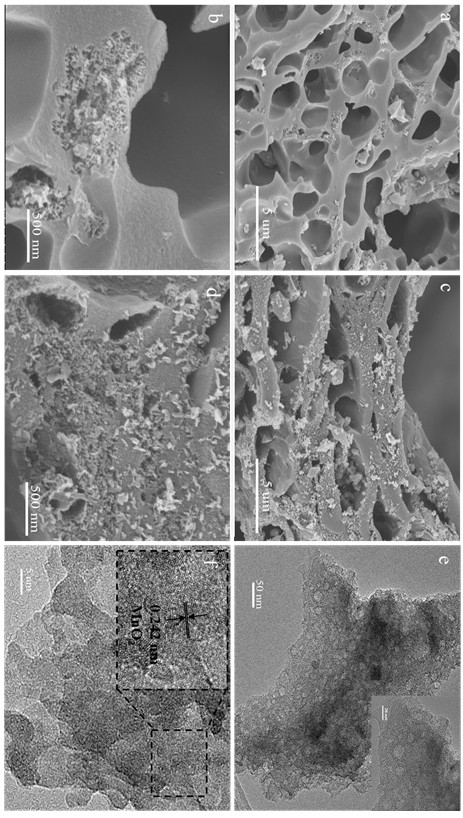

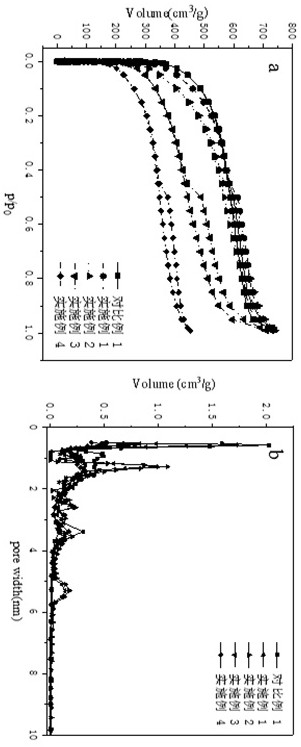

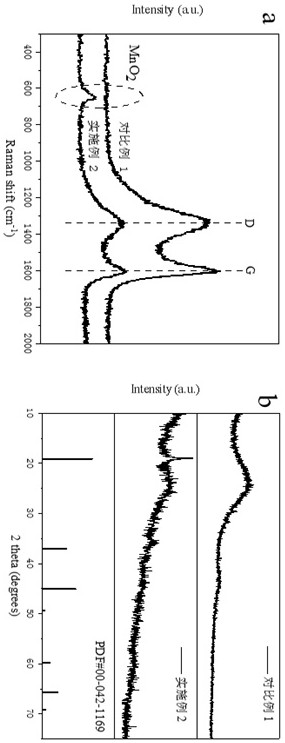

Method used

Image

Examples

Embodiment 1

[0027] (1) Dissolve thiourea and hydrochloric acid in deionized water in a molar ratio of 1:2 to prepare an acidified thiourea solution with a thiourea concentration of 0.05 mol / L;

[0028] (2) Add 0.3g of potassium nitrate and 0.02g of potassium permanganate to 50ml of sodium alginate solution with a mass concentration of 2%, stir evenly, and inject 5ml of the solution into the cylindrical mold respectively, and then drop 5ml of step (1). ) to obtain an acidified thiourea solution, and let stand for 24 hours to prepare a bulk gel;

[0029] (3) washing the bulk gel obtained in step (2) with deionized water until the washing liquid is neutral, and then freeze-drying;

[0030] (4) Carbonizing the lyophilized bulk gel in step (3) at 700° C. under nitrogen protection for 2 h to obtain manganese dioxide composite nitrogen-sulfur double-doped porous carbon.

Embodiment 2

[0032] The amount of potassium permanganate added in step (2) was 0.04 g, and the remaining steps were the same as in Example 1.

Embodiment 3

[0034] The amount of potassium permanganate added in step (2) is 0.06g, and the remaining steps are the same as in Example 1

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com