Networked traction power supply system based on integration of three networks

A technology of traction power supply system and integration of three networks, which is applied in electric braking system, operation center control system, electric vehicle, etc., can solve problems such as difficulty in full utilization, short length of power supply arm, lack of matching, etc., to improve the environment The effect of improving friendliness, improving power supply capacity and eliminating power supply islands

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

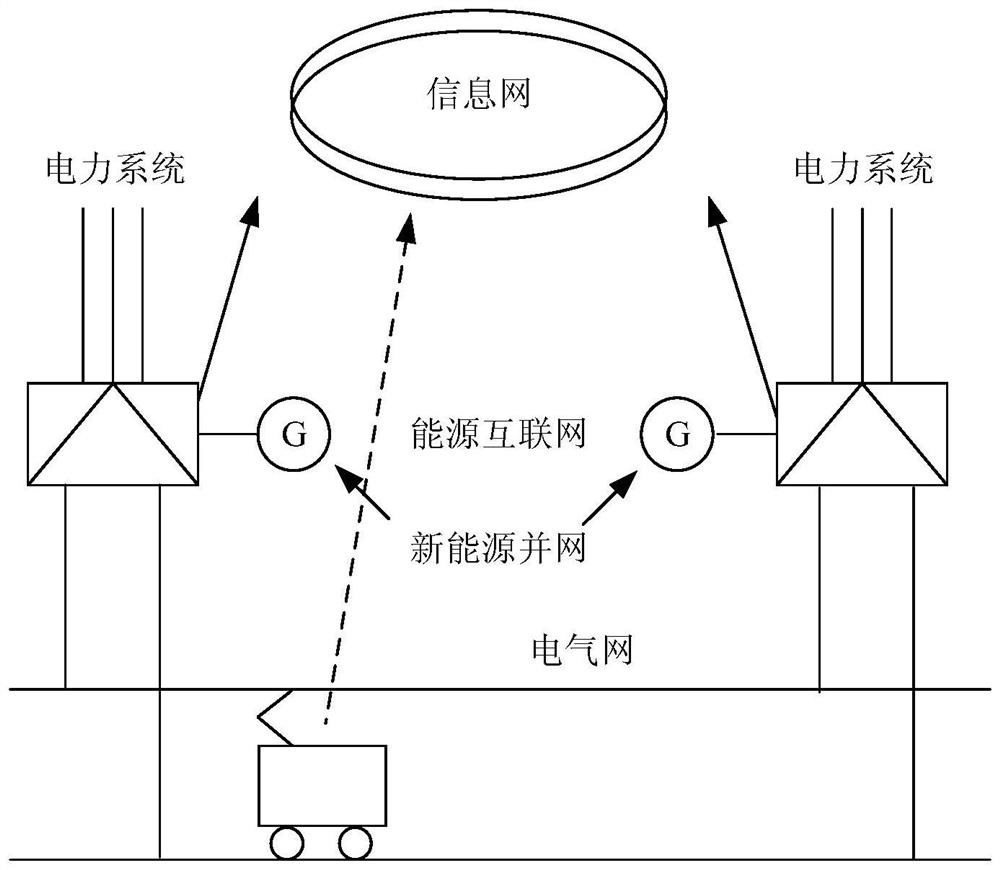

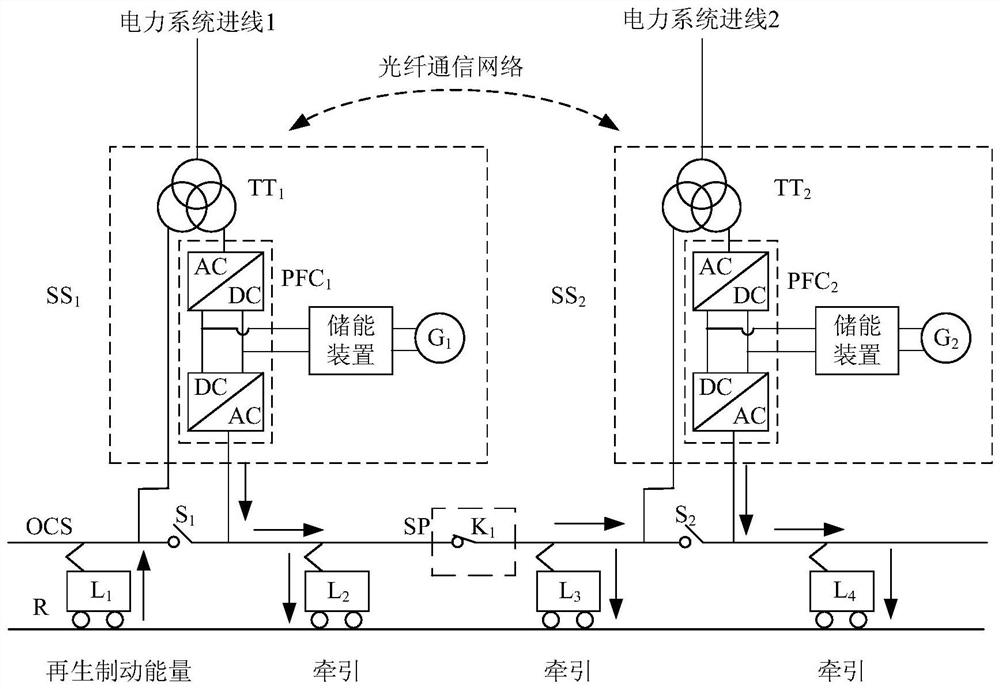

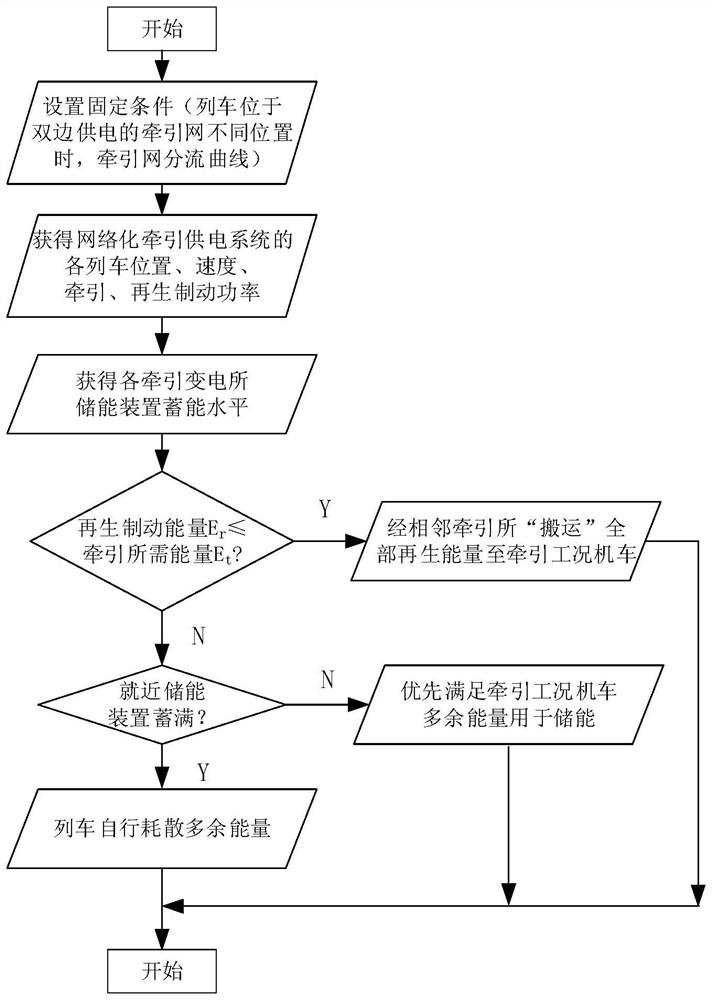

[0030] The networked traction power supply system is based on power electronics technology, learns from flexible power transmission and energy interconnection technologies, integrates railway regenerative braking energy utilization technology, and improves the power flow characteristics of the traction network.

[0031] Realize the power controllability and transferability of the traction power supply system, improve the power supply quality, and thus change the capacity allocation principle of the traction power supply system, greatly improve the adaptability of power supply capacity and driving organization, improve the utilization rate of new energy, and use flexible power electronics and Artificial intelligence technology highlights the close integration of information technology and power electronics technology, solves problems such as power supply and information islands, and realizes the goal of networked and autonomous system operation.

[0032] The networked traction p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com