Application of chaetomium elatum in denitration of nitrocellulose

A technology of nitrocellulose and Chaetomium, which is applied in environmental engineering and biological fields, can solve the problems of complex and cumbersome, inconvenient nitrogen reduction mechanism, unclear mechanism of nitrocellulose, etc., and achieves simple control, good denitrification and denitrification. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1: the preparation of spore suspension and the cultivation of bacterial strain

[0035] This study will come from China General Microorganism Culture Collection Center, the preservation number is CGMCC NO: 3.5617 a strain of Chaetomium tall ( Chaetomium elatum ), insert the culture medium from the inclined surface of the test tube, and use the spore suspension to inoculate.

[0036] The preparation of spore suspension: will come from China General Microorganism Culture Collection Center, preservation number is a strain of chaetomium tall (CGMCC NO:3.5617) Chaetomium elatum ), use an inoculation loop to take a ring of spores from the inclined surface of the test tube, and add 1 mL of sterile water to prepare a spore suspension.

[0037] Liquid culture of strains: 200 µL of spore suspension was added to 100 mL of liquid potato medium for cultivation.

[0038] The composition of the potato medium is as follows: glucose 20.0, unit g / L; potato extract 1000 mL (2...

Embodiment 2

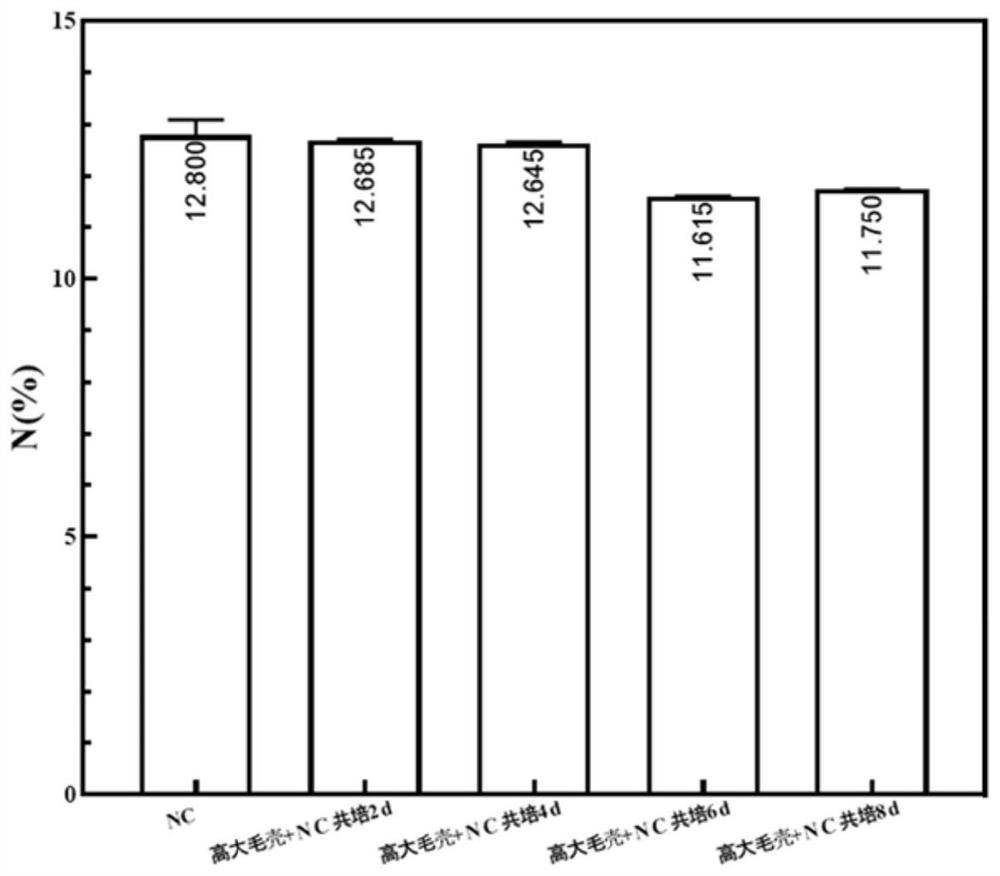

[0043] Embodiment 2: Chaetomium tall under different days ( Chaetomium elatum ) compared to the nitrogen reduction results of nitrocellulose

[0044] Will be purchased from China General Microorganism Culture Collection Center, a strain of Chaetomium tall ( Chaetomium elatum ), use an inoculation loop to take a ring of spores from the slant of the test tube, add 1 mL of sterile water to make a spore suspension, and then add 200 µL of the spore suspension to 100 mL of liquid potato medium for cultivation. In a shaker at 28°C, culture at 200rpm for 2 days until visible cells are formed, and then add 4g / L nitrocellulose as a substrate to carry out substrate conversion reaction with the tall chaetomium strain.

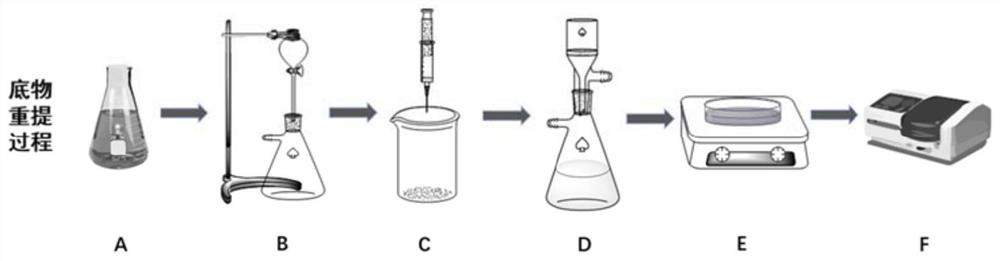

[0045] After the conversion reaction was carried out for 7 days, the cultured substrate nitrocellulose was re-extracted using a suction filtration device to reduce the loss rate of nitrocellulose. After the suction filtration, take the precipitate on the filter paper; wash...

Embodiment 3

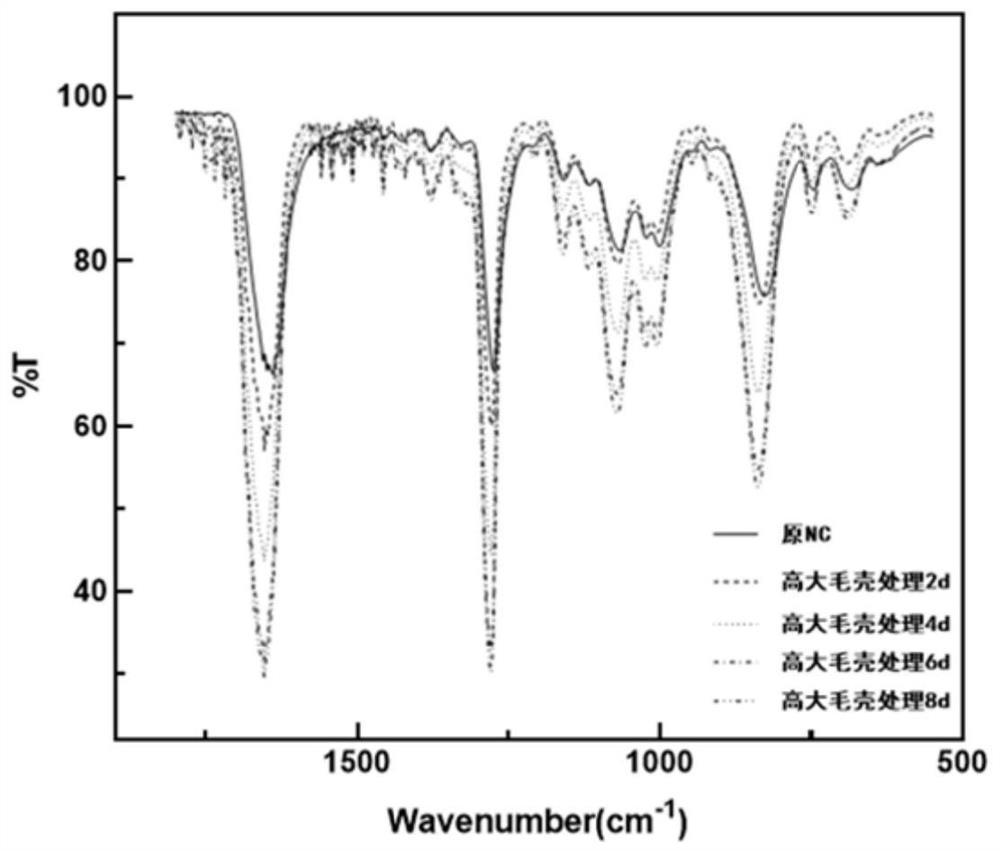

[0047] Embodiment 3: Chaetomium tall under different days ( Chaetomium elatum ) treated nitrocellulose FTIR results comparison.

[0048] The Fourier transform infrared spectra of the nitrocellulose treated with sulfate-reducing bacteria for different days and the original nitrocellulose were compared. 1635cm -1 -ONO 2 Asymmetric stretching vibration, 1274 cm -1 -ONO 2 Symmetric stretching vibration, 1061 cm -1 C-O-C stretching vibration at 996 cm -1 C-O-C stretching vibration at 824 cm -1 is C-O-C stretching vibration. It was found that the main groups of nitrocellulose did not disappear, and no new groups were produced, and the absorption peak of nitro was in Chaetomium tallum ( Chaetomium elatum ) significantly decreased after treatment, and the longer the time, the more obvious the decrease. For details, see figure 2 .

[0049] The denitrification and denitrification of nitrocellulose by the tall Chaetomium strain described in the present invention realizes th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com