Acrylate monomer, preparation method of acrylate monomer, acrylate monomer repairing material and application of acrylate monomer repairing material

A technology of acrylate and repair materials, which is applied in the preparation of carboxylate esters, chemical instruments and methods, and the preparation of organic compounds, and can solve problems such as erosion, poor mechanical properties of materials, and cracks in encapsulated insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

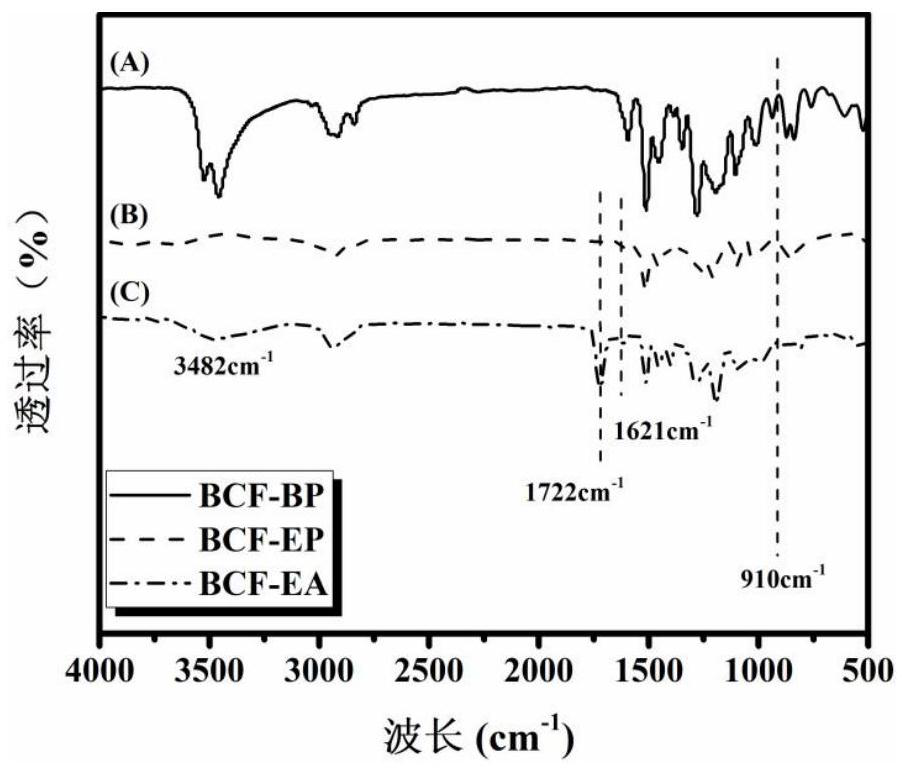

[0035] The present invention provides the preparation method of acrylate monomer described in above-mentioned technical scheme, comprises the following steps:

[0036] (1) Coupling reaction of biomass raw materials with acid and aldehyde-based monomers to obtain bio-based bisphenols;

[0037] (2) Carrying out the ring-opening etherification reaction of the bio-based bisphenol obtained in the step (1) with the catalyst and epichlorohydrin, then adding solvent and sodium hydroxide to carry out the ring-closing reaction to obtain the bio-based epoxy resin;

[0038] (3) The bio-based epoxy resin obtained in the step (2) is subjected to ring-opening reaction with triphenylphosphine, hydroquinone and acrylic monomer to obtain acrylate monomer.

[0039] Unless otherwise specified, the present invention has no special limitation on the sources of the above-mentioned components, and commercially available products or products prepared by conventional preparation methods well known to t...

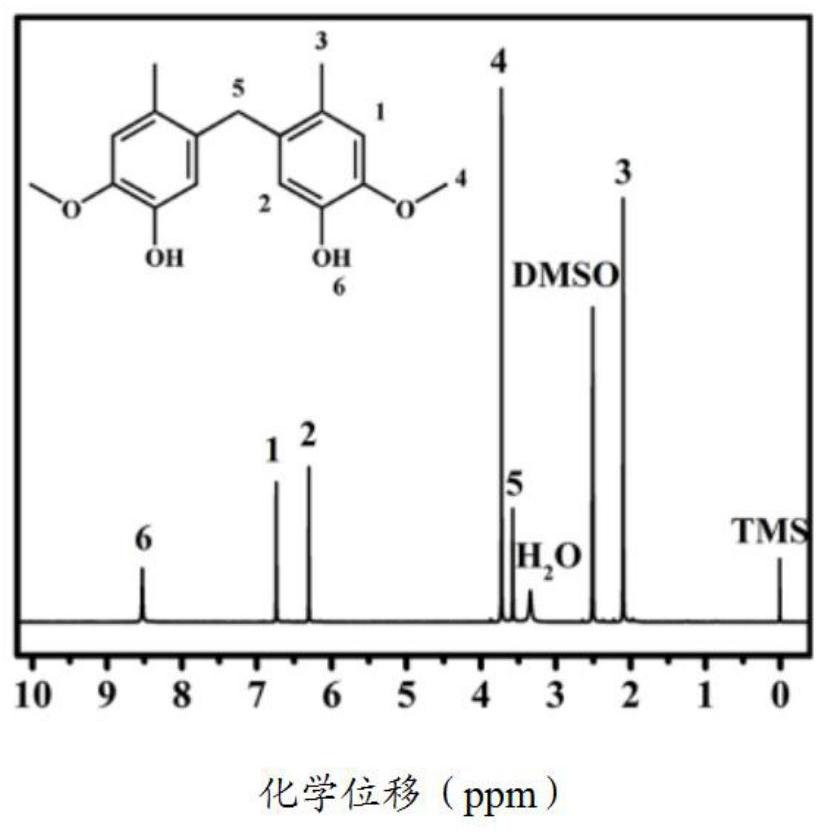

Embodiment 1

[0089](1) Under nitrogen protection, in a three-necked flask equipped with mechanical stirring, a thermometer and a reflux condensing device, add 0.22mol of 4-methylguaiacol and 7mL of 85% phosphoric acid (the substance of 4-methylguaiacol The volume ratio of the amount of phosphoric acid and phosphoric acid is 0.22mol:7mL), after stirring at 200r / min for 5min, the temperature is raised to 50°C, the system is kept at a constant temperature for 30min, and an aqueous solution of 0.1mol formaldehyde is added dropwise (the mass concentration of formaldehyde is 37%, 4-methyl The ratio of the amount of guaiacol and formaldehyde is 2.2:1, the dropping rate is 8s / 0.05mL), the temperature is raised to 90°C for 6h, and a golden red product is obtained. After the product is lowered to room temperature, it is washed with water until neutral, and Toluene was used as solvent for recrystallization, followed by column chromatography to obtain a white crystal product, bio-based bisphenol BCF-BP...

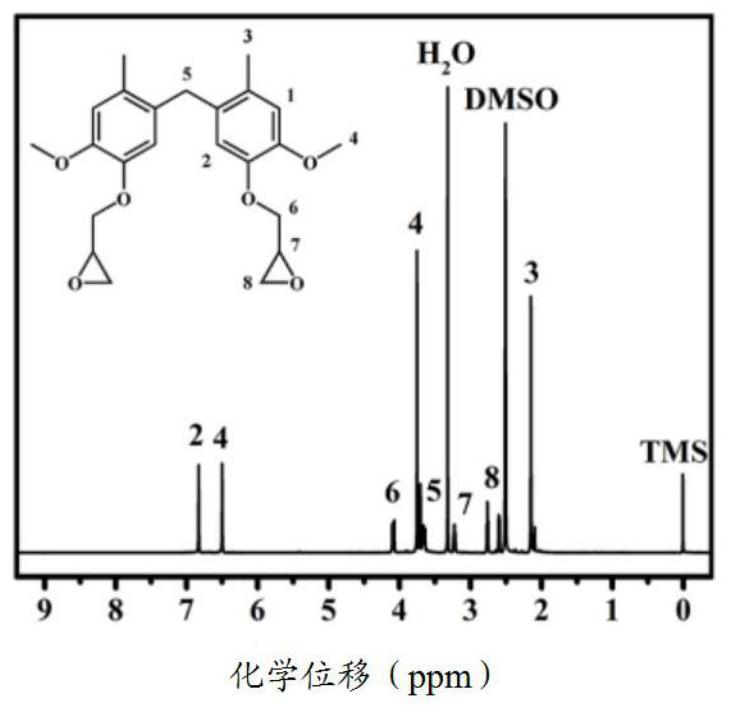

Embodiment 2

[0095] (1) Under nitrogen protection, in a three-necked flask equipped with mechanical stirring, a thermometer and a reflux condensing device, add 0.22mol of 4-methylguaiacol and 7mL of 85% phosphoric acid (the substance of 4-methylguaiacol The volume ratio of the amount of phosphoric acid and phosphoric acid is 0.22mol:7mL), after stirring at 200r / min for 5min, the temperature is raised to 50°C, the system is kept at a constant temperature for 30min, and an aqueous solution of 0.1mol formaldehyde is added dropwise (the mass concentration of formaldehyde is 37%, 4-methyl The ratio of the amount of guaiacol and formaldehyde is 2.2:1, the dropping rate is 8s / 0.05mL), the temperature is raised to 90°C for 6h, and a golden red product is obtained. After the product is lowered to room temperature, it is washed with water until neutral, and Toluene was used as solvent for recrystallization, followed by column chromatography to obtain a white crystal product, bio-based bisphenol BCF-B...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com