High-concentration cholesterol culture medium as well as preparation method and application thereof

A cholesterol, high-concentration technology, applied in the field of cholesterol degradation research, can solve the problems of complicated medium configuration process, inability to complete the configuration, 2-3 days, etc., to achieve uniform and stable distribution of cholesterol, not easy to precipitate, and long storage time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A cholesterol sterile CD liquid medium, the content of effective components of the medium includes: sodium nitrate 0.2g / 100mL, potassium dihydrogen phosphate 0.1g / 100mL, magnesium sulfate 0.05g / 100mL, potassium chloride 0.05g / 100mL , sodium chloride 0.05g / 100mL, ferrous sulfate 0.002g / 100mL, cholesterol 1.5g / 100mL and water.

[0031] Its preparation method concrete steps are:

[0032] S1. Accurately weigh sodium nitrate, potassium dihydrogen phosphate, magnesium sulfate, potassium chloride, sodium chloride, and ferrous sulfate with an electronic balance, add deionized water to dissolve, pack in a triangular flask, and seal;

[0033] S2. Sterilize the sealed triangular flask containing the medium in an autoclave at a temperature of 121°C for 20 minutes, and store it at 4°C to obtain a sterile CD liquid medium. stand-by;

[0034] S3. Spread the weighed cholesterol on a class 100 ultra-clean bench, close the glass window of the ultra-clean bench, and carry out ultraviole...

Embodiment 2

[0039] A cholesterol sterile CD solid medium, the effective component content of the medium includes: sodium nitrate 0.2g / 100mL, potassium dihydrogen phosphate 0.1g / 100mL, magnesium sulfate 0.05g / 100mL, potassium chloride 0.05g / 100mL , sodium chloride 0.05g / 100mL, ferrous sulfate 0.002g / 100mL, agar 1.5g / 100mL, cholesterol 1.5g / 100mL and water.

[0040] Its preparation method concrete steps are:

[0041] S1. Accurately weigh sodium nitrate, potassium dihydrogen phosphate, magnesium sulfate, potassium chloride, sodium chloride, ferrous sulfate, agar, and deionized water to dissolve with an electronic balance, pack in a triangular flask, and seal;

[0042] S2. Sterilize the sealed triangular flask containing the medium in an autoclave at a temperature of 121°C for 20 minutes, and store it at 4°C to obtain a sterile CD solid medium. stand-by;

[0043] S3. Spread the weighed cholesterol on a class 100 ultra-clean bench, close the glass window of the ultra-clean bench, and carry o...

Embodiment 3

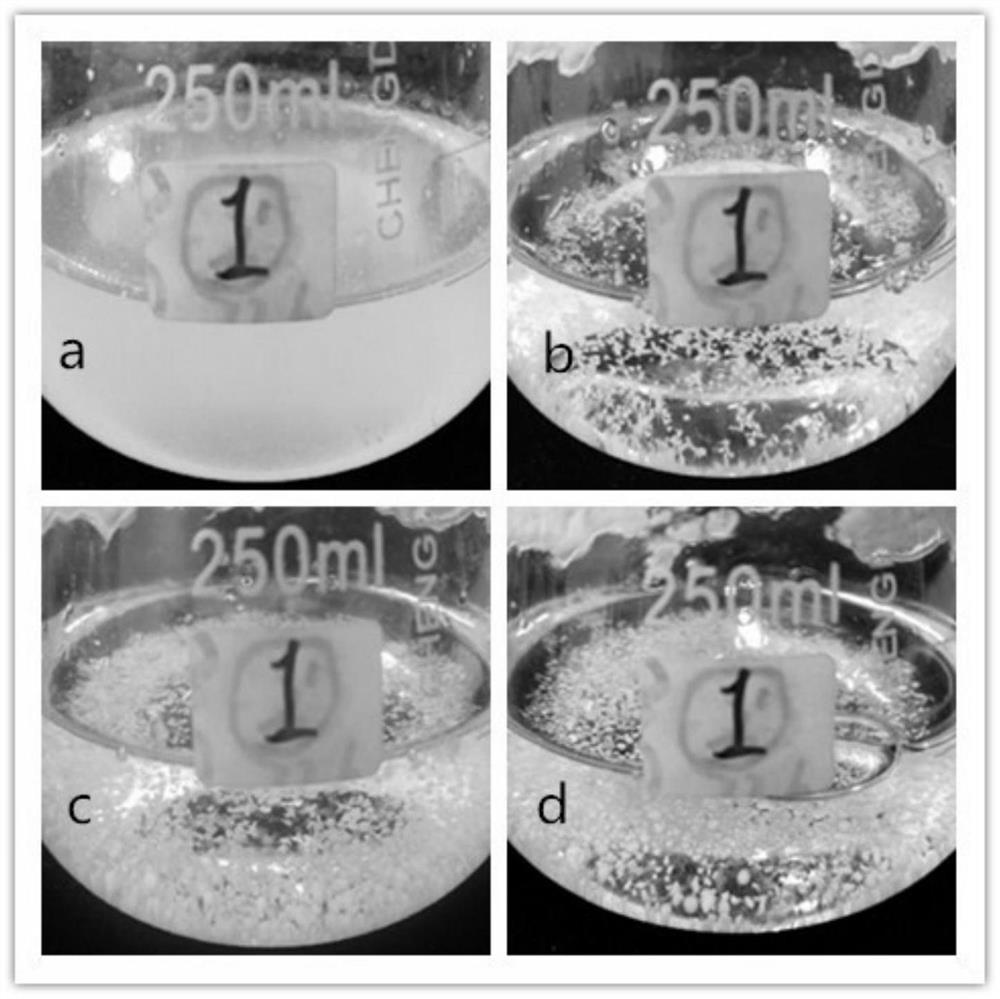

[0048] Add 100 μ L of Aspergillus oryzae spore suspension in the high-concentration cholesterol CD liquid medium of embodiment 1 (cholesterol concentration is 1.5g / 100ml, loading is 100mL) and grows, will add the cholesterol CD medium of Aspergillus oryzae spore suspension , placed in a shaker at 30°C for 96 hours of fermentation, the appearance photos of its growth at different times are as follows figure 1 Shown, where a is 0h; b is 48h; c is 72h; d is 96h. Depend on figure 1 It can be seen that as time increases, the medium changes from turbid to clear after 48 hours, because cholesterol is insoluble in water, so it shows that cholesterol in high-concentration cholesterol medium decreases with time, and Aspergillus oryzae gradually utilizes and metabolizes cholesterol. Illustrate that the high-concentration cholesterol CD liquid medium provided by the present invention can be used for research in the field of cholesterol, and in this medium, Aspergillus oryzae has higher m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com