Low-energy-consumption double-film pressurized greenhouse

A low energy consumption and greenhouse technology, applied in horticulture, greenhouse cultivation, climate change adaptation, etc., can solve the problems of low vegetable and fruit prices, consumption of manpower and financial resources, and decline in economic returns, so as to increase plant yield, enhance heat preservation effect, The effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

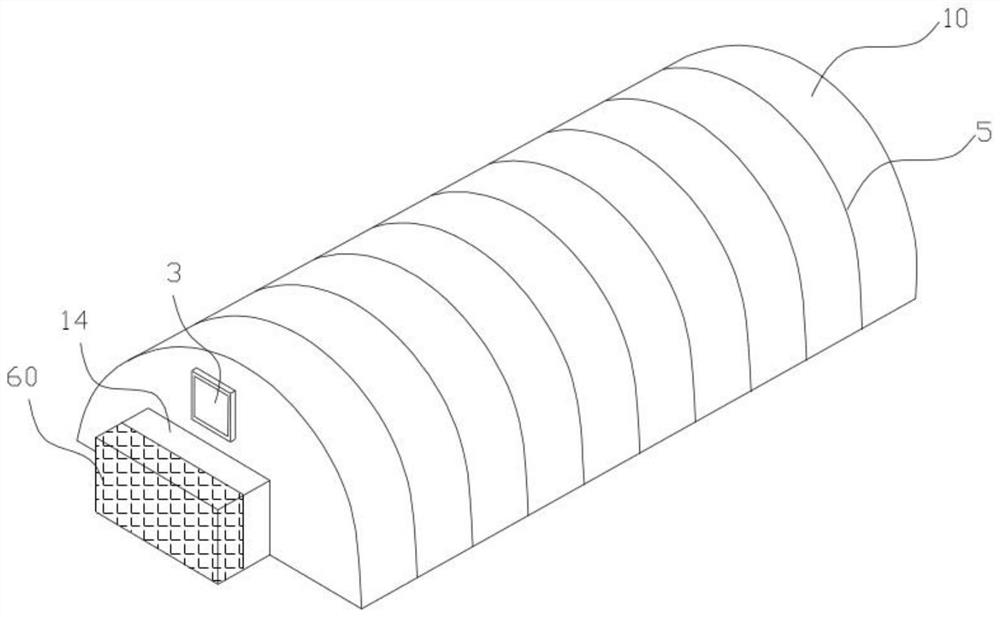

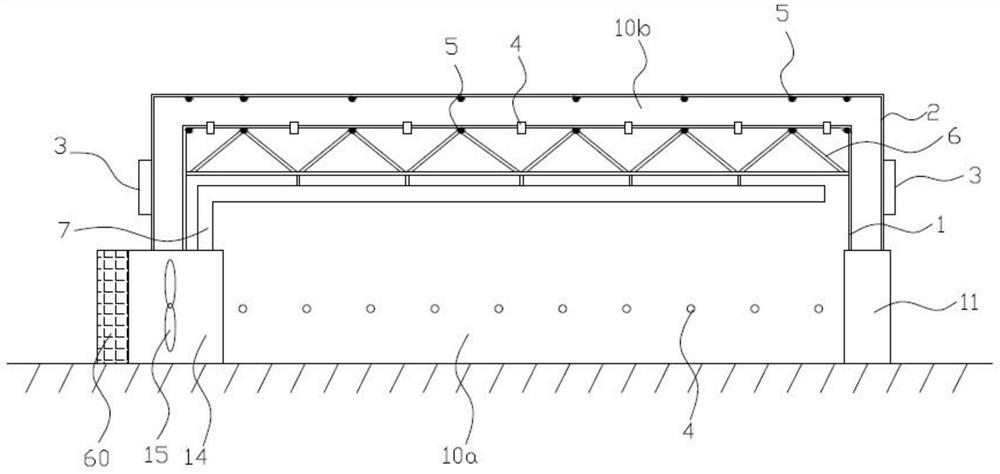

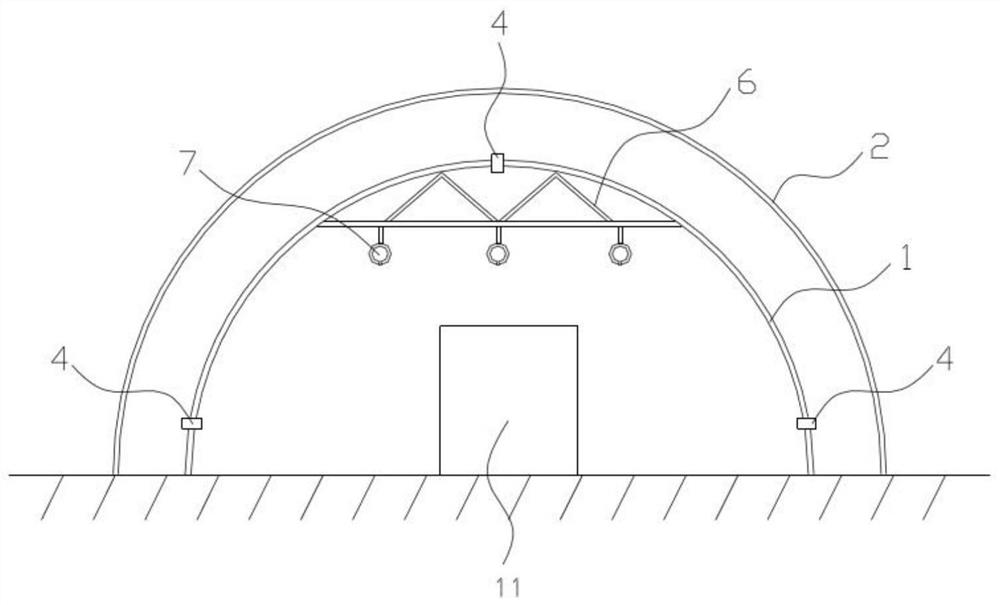

[0048] Such as Figure 1-3 The shown low-energy double-membrane pressurized greenhouse includes a greenhouse body 10 composed of an inner membrane 1 and an outer membrane 2, an air supply part 14 arranged at one end of the greenhouse body 10, and an air supply part 14 arranged at the other end of the greenhouse body 10. The entrance and exit 11, the inner membrane 1 and the outer membrane 2 divide the interior of the greenhouse into an inner building 10a and an outer building 10b, and the air supply part 14 supplies the outside air into the inner building 10a, so that the air pressure in the inner building 10a is greater than that of the outside air pressure;

[0049] Both the inner membrane 1 and the outer membrane 2 are made of environmentally friendly and degradable polymer materials, and the service life can reach about 8 years. The anti-drip and defogging effects are synchronized with the life of the membrane. The compressed air belt acts as a heat transfer buffer, repla...

Embodiment 2

[0062] Such as Figure 4 As shown, this embodiment is the same as Embodiment 1, except that: when water needs to be poured into the greenhouse, a water supply unit 60 is also provided at the air inlet of the air supply unit 14 . The function of the water supply part 60 is to reduce or increase the temperature of the air at the air inlet of the air supply part 14 .

[0063] The water supply part 60 includes a frame body 20, the frame body 20 surrounds the air inlet of the air supply part 14, a filter 30 arranged in the side wall of the frame body 20, and a water supply line 70 arranged on the frame body 20; The filter 30 is full of holes, and the holes of the filter 30 are formed in a direction crossing each other on a plane, and the filter 30 can absorb water dropped from the water supply line 70 and remove foreign matter in the external air; The lower part of the main body 20 is provided with a drain line 21 capable of recovering water dropped from the water supply line 70 ....

Embodiment 3

[0067] Such as Figure 17 As shown, this embodiment is the same as Embodiment 1, the difference is that, in addition to the inner membrane 1 and the outer membrane 2, the greenhouse is also provided with a middle membrane 9 between the inner membrane 1 and the outer membrane 2, and the middle membrane 9. Separate the outer building 10b into an outer building 10c and an outer second building 10d. Check valves 4 are provided on the top and bottom sides of the inner membrane 1 and the middle membrane 9, and the outer membrane 2 is provided with an exhaust valve. window3.

[0068] After adding one layer of middle film 9, one more layer of high-pressure air belt can be added as a heat transfer buffer zone, which can further effectively reduce heat loss.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com