Sulfur-containing waste gas desulfurization emulsion as well as preparation method and application thereof

A technology for desulfurization and emulsion of waste gas, applied in separation methods, chemical instruments and methods, zinc sulfate, etc., can solve the problems of unsatisfactory removal of sulfur dioxide, easy blockage of absorption equipment, filtration equipment and pipelines, affecting system production, etc. Achieving a good removal effect, the preparation method is simple and convenient, and the effect of improving the absorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

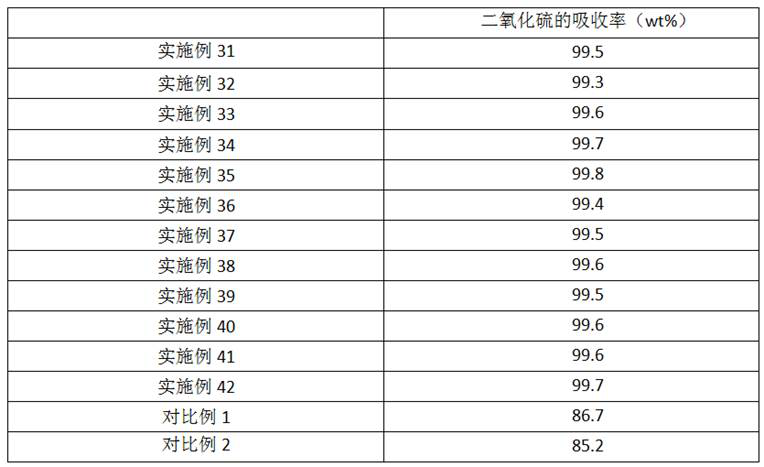

Examples

preparation example Construction

[0028] The preparation method of the sulfur-containing exhaust gas desulfurization emulsion is to mix zinc oxide powder, water and oil, and emulsify. The mixing method can be well-known to those skilled in the art, such as stirring and ultrasonic mixing.

[0029] Preferably, the pH of the system is adjusted to 6.0-8.0 during emulsification.

[0030] The application of the sulfur-containing waste gas desulfurization emulsion is to pass the sulfur-containing waste gas into the desulfurization emulsion for desulfurization.

[0031] Preferably, the content of sulfur dioxide in the sulfur-containing exhaust gas is 2000~2200mg / Nm 3 , the desulfurization process controls the final pH of the emulsion to ≥ 4.5, and the pressure difference between the exhaust gas inlet wind pressure and the exhaust gas outlet wind pressure is 0.35~0.45kPa during the desulfurization process.

Embodiment 1

[0034] The sulfur-containing waste gas desulfurization emulsion includes zinc suboxide powder, water and oil, the mass concentration of zinc suboxide powder in the emulsion is 5wt%, and the volume ratio of water and oil is 1:1.

Embodiment 2

[0036] The sulfur-containing exhaust gas desulfurization emulsion includes zinc suboxide powder, water and oil, the mass concentration of zinc suboxide powder in the emulsion is 30wt%, and the volume ratio of water and oil is 10:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com