Terbium ion doped up-conversion nano material and preparation method thereof

A nanomaterial and ion doping technology is applied in the field of terbium ion-doped Ho3+-based up-conversion nanomaterials and their preparation, which can solve the problems of fluorescence quenching, limited application in the biological field, etc., and achieves low equipment cost, short preparation period, Simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

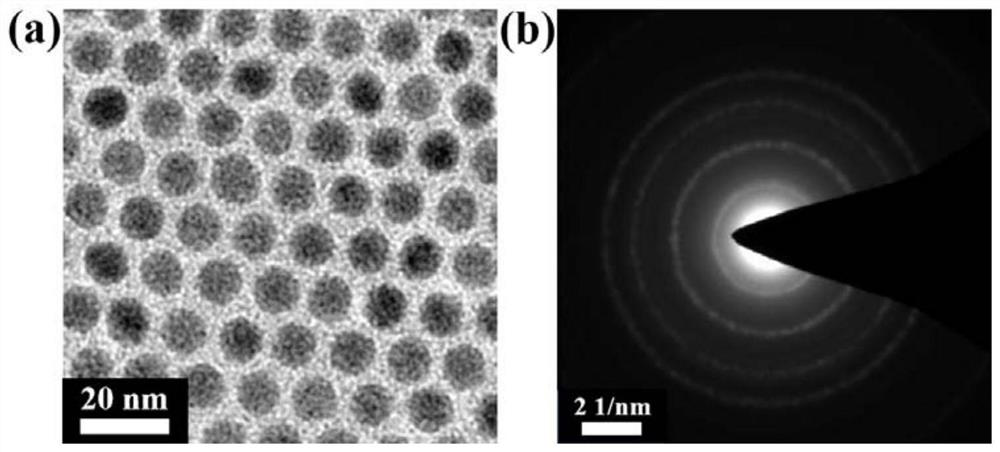

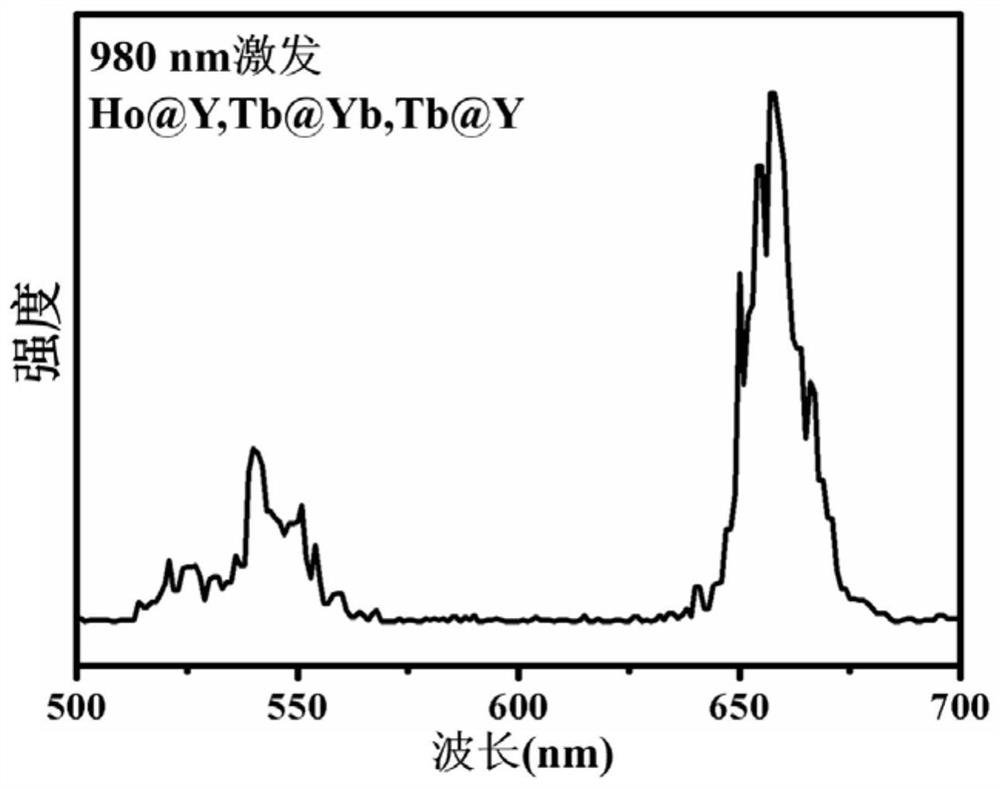

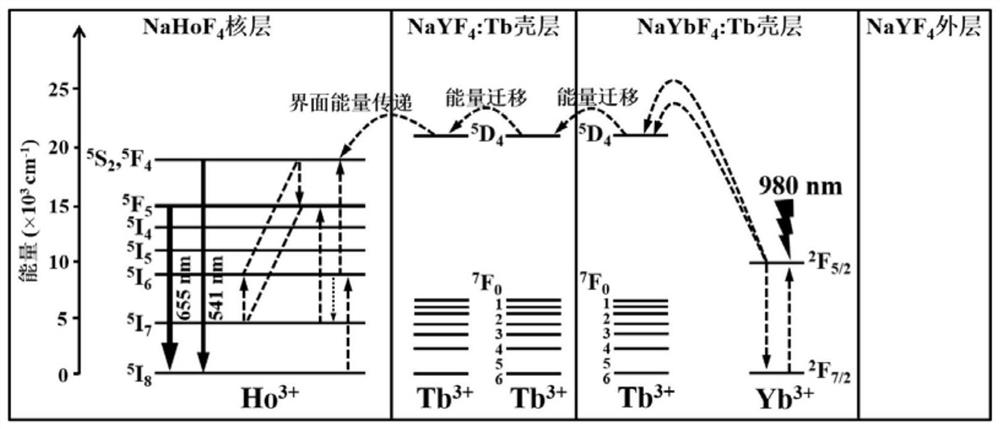

[0075] This embodiment provides a NaHoF 4 @NaYF 4 :75%Tb@NaYbF 4 :30%Tb@NaYF 4 Preparation methods of upconversion nanomaterials.

[0076] (1)NaHoF 4 Nuclear layer preparation: put 15mL oleic acid and 20mL octadecene into a 100mL three-necked flask, mix and stir evenly. Then add 1mL concentration of 1mol L -1 Holmium chloride solution, mix and stir evenly, then raise the temperature to 105°C and keep it for 40min to remove water. Then the temperature was raised to 150°C and kept for 40 minutes to form a rare earth-oleic acid chelate. Then the temperature was naturally cooled to room temperature, 0.1 g of sodium hydroxide (2.5 mmol) and 0.148 g of ammonium fluoride (4 mmol) in methanol (10 mL in total) were added to the above mixture and stirred, then the temperature was raised to 90 °C and kept for 1 h , to remove excess methanol. Then, under the protection of argon, the temperature was raised to 280° C. for 1 h. Finally, the cloudy solution after the reaction was nat...

Embodiment 2

[0081] This embodiment provides a NaHoF 4 @NaYF 4 :73.5%Tb@NaYbF 4 :28.5%Tb@NaYF 4 Preparation methods of upconversion nanomaterials.

[0082] (1)NaHoF 4 Nuclear layer preparation: put 13.6mL oleic acid and 20mL octadecene into a 100mL three-necked flask, mix and stir evenly. Then add 1mL concentration of 1mol L -1 Holmium chloride solution, mix and stir evenly, then raise the temperature to 98°C and keep it for 40min to remove water. Then the temperature was raised to 148° C. and kept for 40 minutes to form a rare earth-oleic acid chelate. Then the temperature was naturally cooled to room temperature, 0.1 g of sodium hydroxide (2.5 mmol) and 0.148 g of ammonium fluoride (4 mmol) in methanol (10 mL in total) were added to the above mixture and stirred, then the temperature was raised to 88 °C and kept for 1 h , to remove excess methanol. Then, under the protection of argon, the temperature was raised to 278° C. for 1 h. Finally, the cloudy solution after the reaction wa...

Embodiment 3

[0087] This embodiment provides a NaHoF 4 @NaYF 4 :76.5%Tb@NaYbF 4 :31.5%Tb@NaYF 4 Preparation methods of upconversion nanomaterials.

[0088] (1)NaHoF 4 Nuclear layer preparation: put 16.4mL oleic acid and 20mL octadecene into a 100mL three-necked flask, mix and stir evenly. Then add 1mL concentration of 1mol L -1 Holmium chloride solution, mix and stir evenly, then raise the temperature to 112°C and keep it for 40min to remove water. Then the temperature was raised to 152° C. and kept for 40 minutes to form a rare earth-oleic acid chelate. Then the temperature was naturally cooled to room temperature, 0.1 g of sodium hydroxide (2.5 mmol) and 0.148 g of ammonium fluoride (4 mmol) in methanol (10 mL in total) were added to the above mixture and stirred, then the temperature was raised to 92 °C and kept for 1 h , to remove excess methanol. Then, under the protection of argon, the temperature was raised to 282° C. for 1 h. Finally, the cloudy solution after the reaction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com