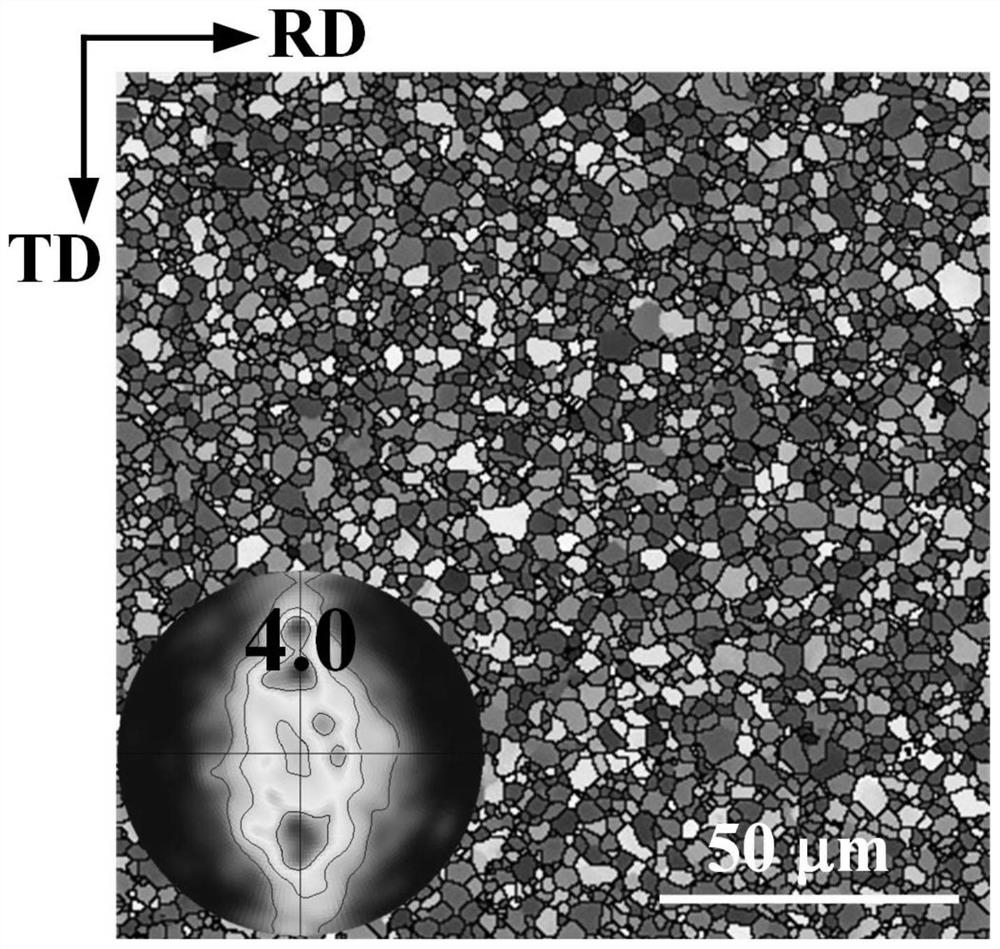

Rapid age hardening multi-element microalloy weak texture magnesium alloy and preparation method thereof

An age-hardening and micro-alloying technology, which is applied in metal rolling, manufacturing tools, heat treatment equipment, etc., can solve problems such as high solid solubility, energy consumption, and failure to meet industrial needs, and achieve low alloy content and suppress grains The effect of growing up

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Alloy in terms of mass percentage: Zn: 0.9%, Ca: 0.5%, Sn: 0.3%; Mn: 0.2%; unavoidable impurity content is less than 0.02%, and the balance is magnesium, hereinafter referred to as Mg-0.9Zn-0.5Ca- 0.3Sn-0.2Mn, Mg-0.9Zn-0.5Ca-0.3Sn-0.2Mn preparation method is as follows:

[0033] (1) in SF 6 and CO 2 Under the protection of the mixed gas, the pure magnesium ingot is preheated to 500°C in the crucible, and then heated to 690°C for melting to obtain a pure magnesium melt;

[0034] (2) pure zinc, magnesium-calcium master alloy, pure tin and magnesium-manganese master alloy are added in the pure magnesium melt that step (1) obtains, after being incubated at 680 ℃ for 15 minutes, through stirring 2-10 minute, then Refining by blowing argon, cleaning slag, removing impurities and oxidation products to obtain magnesium alloy melt;

[0035] (3) The magnesium alloy melt obtained in step (2) is left to stand, kept warm, and then poured into a mold to obtain a magnesium alloy in...

Embodiment 2

[0042] Alloy in terms of mass percentage: Zn: 0.95%, Ca: 0.5%, Sn: 0.3%; Mn: 0.2%; unavoidable impurity content is less than 0.02%, and the balance is magnesium, hereinafter referred to as Mg-0.95Zn-0.45Ca- 0.3Sn-0.2Mn, Mg-0.95Zn-0.45Ca-0.3Sn-0.2Mn preparation method is as follows:

[0043] (1) in SF 6 and CO 2 Under the protection of the mixed gas, the pure magnesium ingot is preheated to 500°C in the crucible, and then heated to 680°C for melting to obtain a pure magnesium melt;

[0044] (2) pure zinc, magnesium-calcium master alloy, pure tin and magnesium-manganese master alloy are added in the pure magnesium melt that step (1) obtains, after being incubated at 680 ℃ for 15 minutes, after stirring for 2-10 minutes, Then refine by blowing argon, remove slag, remove impurities and oxidation products, and obtain magnesium alloy melt;

[0045] (3) The magnesium alloy melt obtained in step (2) is left to stand, kept warm, and then poured into a mold to obtain a magnesium allo...

Embodiment 3

[0052] The alloy is calculated in terms of mass percentage: Zn: 0.8%, Ca: 1.0%, Sn: 0.5%; Mn: 0.5%; the unavoidable impurity content is less than 0.02%, and the balance is magnesium, hereinafter referred to as Mg-0.8Zn-1.0Ca- 0.5Sn-0.5Mn, Mg-0.8Zn-1.0Ca-0.5Sn-0.5Mn preparation method is as follows:

[0053] (1) in SF 6 and CO 2 Under the protection of the mixed gas, the pure magnesium ingot is preheated to 500°C in the crucible, and then heated to 700°C for melting to obtain a pure magnesium melt;

[0054] (2) pure zinc, magnesium-calcium master alloy, pure tin and magnesium-manganese master alloy are added in the pure magnesium melt that step (1) obtains, after being incubated at 680 ℃ for 15 minutes, after stirring for 2-10 minutes, Then refine by blowing argon, remove slag, remove impurities and oxidation products, and obtain magnesium alloy melt;

[0055] (3) The magnesium alloy melt obtained in step (2) is left to stand, kept warm, and then poured into a mold to obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com