Cobalt oxide nanosheet chlorine evolution electrode, preparation method and application thereof

A technology for nanosheets and chlorine evolution electrodes is applied in the field of cobalt oxide nanosheet chlorine evolution electrodes and their preparation, which can solve the problems of high cost of electrode preparation, and achieve the effects of excellent electrocatalytic efficiency, high catalytic activity and simple conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

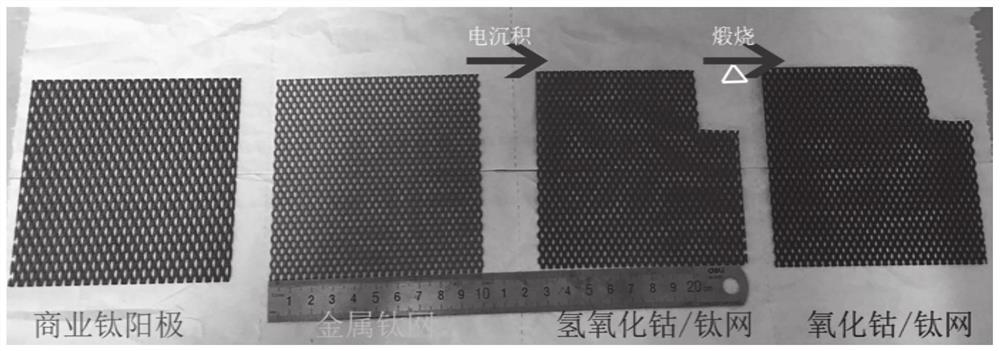

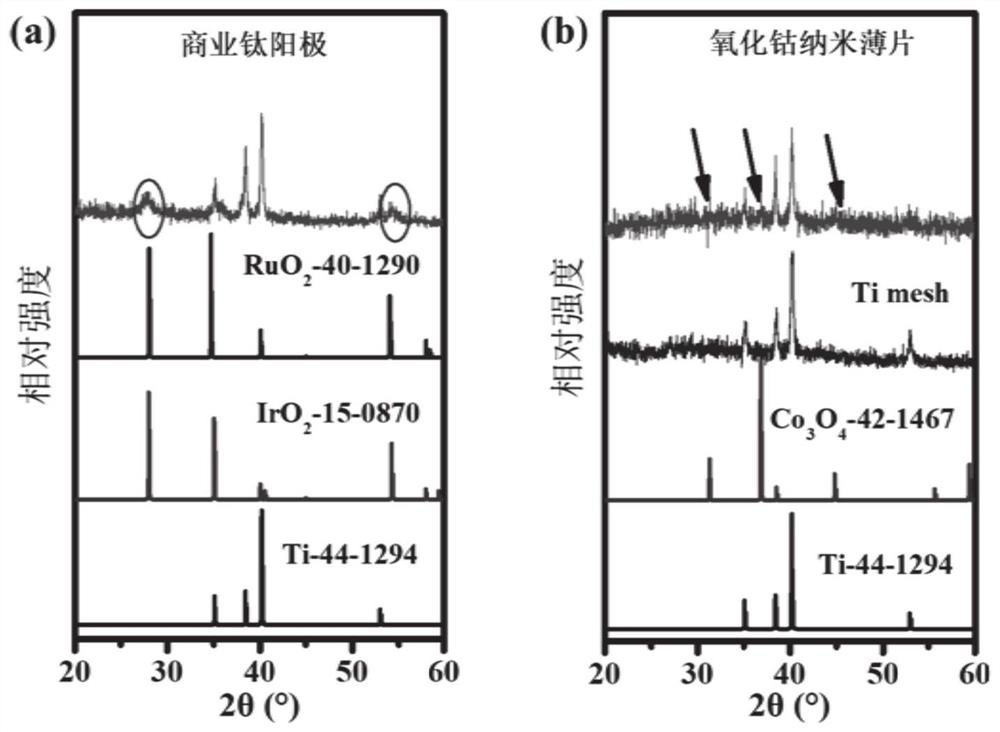

[0035] A method for preparing a cobalt oxide nanosheet chlorine analysis electrode that is easy to industrialized production comprises the following steps:

[0036] (1) Ultrasonic cleaning of metal titanium mesh:

[0037] First cut with scissors to obtain a 1.0cm×2.0cm titanium metal mesh, then ultrasonically clean it with acetone, ethanol, and deionized water for 30 minutes, and finally place it in an ethanol solvent.

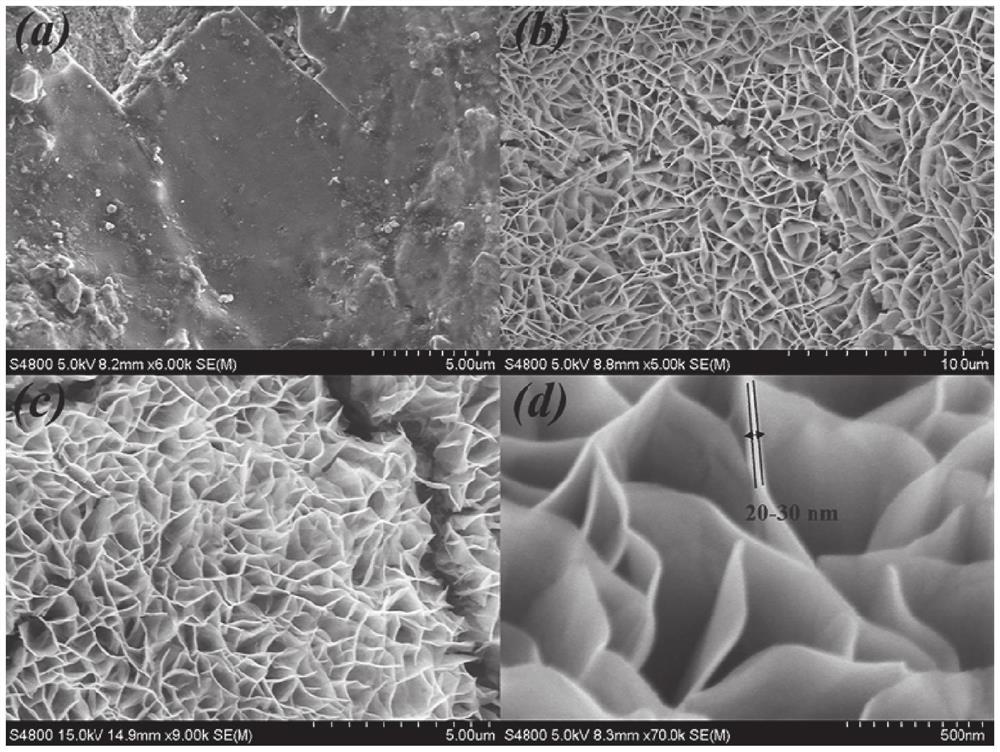

[0038] (2) Electrodeposition of cobalt hydroxide flakes:

[0039] The 0.1mol / L cobalt nitrate solution prepared in advance deposits cobalt hydroxide on the substrate by controlling the deposition voltage and deposition charge. The deposition voltage is controlled at -0.75V (vs.Ag / AgCl), and the deposition charge is controlled at 3.0C / cm 2 . Get Co(OH) 2 / Ti.

[0040] (3) Calcination to obtain Co 3 O 4 / Ti electrode:

[0041] Co(OH) prepared in step (2) 2 / Ti is placed in a muffle furnace, the heating rate is set to 5°C / min, and it is kept at 300°C for...

Embodiment 2

[0043] The preparation method is the same as that in Example 1, except that the change of annealing temperature in step (3) is 250°C.

Embodiment 3

[0045] The preparation method is the same as that in Example 1, except that the change of annealing temperature in step (3) is 350°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com