Preparation method of direct alcohol fuel cell anode catalytic material

A technology for fuel cells and catalytic materials, applied in battery electrodes, metal material coating processes, circuits, etc., can solve the problems of loss of catalytic effect, high price of precious metal materials, and inability to be widely used in direct alcohol fuel cells, etc. Production efficiency, good contact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] 1) Choose a Si(100) single wafer as the substrate, first cut the large silicon substrate into small square pieces of 20×20mm, clean the substrate with absorbent cotton, wipe off the impurities adsorbed on the surface of the substrate, and then use Ultrasonic cleaning with acetone, alcohol and distilled water for 20 minutes, after drying, put it into a vacuum chamber to prepare for depositing a film;

[0018] 2) The target material is Cu 60 Zr 34 Ti 1 Ni 5 , The bottom of the target is flat and in good contact with the target, which can ensure maximum heat dissipation.

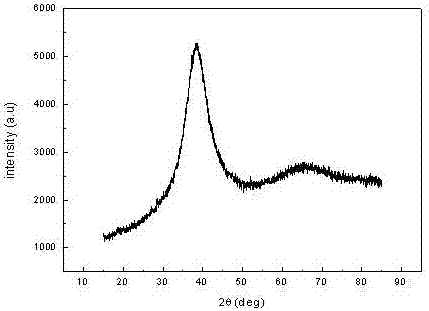

[0019] 3) The deposition film equipment adopts the magnetron sputtering coating system, and the target material is Cu 60 Zr 34 Ti 1 Ni 5 Align the Si substrate at the upper center, and evacuate the vacuum chamber to 3×10 before depositing the film. -4 Pa, and then pass high-purity argon. Precisely control the opening time of the baffle on the target by computer to deposit palladium film and copp...

Embodiment 2

[0022] 1) Choose a Si(100) single wafer as the substrate, first cut the large silicon substrate into small square pieces of 20×20mm, clean the substrate with absorbent cotton, wipe off the impurities adsorbed on the surface of the substrate, and then use Ultrasonic cleaning with acetone, alcohol and distilled water for 20 minutes, after drying, put it into a vacuum chamber to prepare for depositing a film;

[0023] 2) The target material is Cu 60 Zr 34 Ti 3 Ni 3 , The bottom of the target is flat and in good contact with the target, which can ensure maximum heat dissipation.

[0024] 3) The deposition film equipment adopts the magnetron sputtering coating system, and the target material is Cu 60 Zr 34 Ti 3 Ni 3 Align the Si substrate at the upper center, and evacuate the vacuum chamber to 3×10 before depositing the film. -4 Pa, and then pass high-purity argon. Precisely control the opening time of the baffle on the target by computer to deposit palladium film and copp...

Embodiment 3

[0027] 1) Choose a Si(100) single wafer as the substrate, first cut the large silicon substrate into small square pieces of 20×20mm, clean the substrate with absorbent cotton, wipe off the impurities adsorbed on the surface of the substrate, and then use Ultrasonic cleaning with acetone, alcohol and distilled water for 20 minutes, after drying, put it into a vacuum chamber to prepare for depositing a film;

[0028] 2) The target material is Cu 60 Zr 34 Ti 1 Ni 5 , The bottom of the target is flat and in good contact with the target, which can ensure maximum heat dissipation.

[0029] 3) The deposition film equipment adopts the magnetron sputtering coating system, and the target material is Cu 60 Zr 34 Ti 1 Ni 5Align the Si substrate at the upper center, and evacuate the vacuum chamber to 3×10 before depositing the film. -4 Pa, and then pass high-purity argon. Precisely control the opening time of the baffle on the target by computer to deposit palladium film and coppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com