Photocatalytic self-cleaning functional cotton fabric and preparation method thereof

A cotton fabric, self-cleaning technology, used in plant fibers, textiles and papermaking, fiber processing and other directions, can solve problems such as being easily soluble in water and difficult to recycle, and achieve strong electron transmission capacity, no secondary pollution, and inhibition of recombination. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Step 1. Weigh 0.0742g of ammonium molybdate tetrahydrate and 0.0564g of copper nitrate in a beaker, add 10ml of water, and stir at 20°C until it dissolves to obtain a mixed solution;

[0024] Step 2. Weigh 0.0138g of 1,2,4-triazole, add it into the mixed solution, and dissolve it by ultrasonic treatment at 20°C for 20 minutes. Use hydrochloric acid and sodium hydroxide with a concentration of 1mol / L to adjust the pH of the solution to 2.5, stir at room temperature for 30 minutes to obtain the treatment solution;

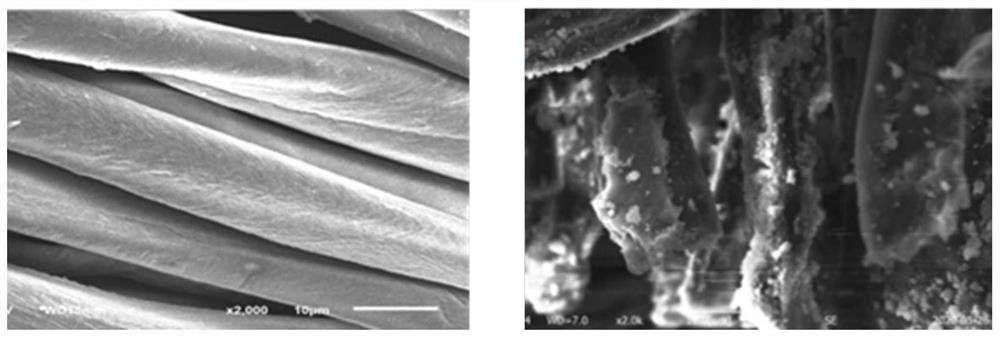

[0025] Step 3. Immerse 5g of cotton fabric in a NaOH solution with a mass fraction of 2% at a bath ratio of 1:50, wash at 80°C, dry after washing, and then immerse the mass fraction at a bath ratio of 1:30 In a 10% sodium chloroacetate solution, react at room temperature for 5 minutes, take it out, wash it, and dry it to obtain a cotton fabric treated with etherification modification;

[0026] Step 4. Put the etherified cotton fabric in step 3 into the treatm...

Embodiment 2

[0028] Step 1. Weigh 0.1236g of ammonium molybdate tetrahydrate and 0.0752g of copper nitrate in a beaker, add 30ml of n-propanol, and stir at 30°C until it dissolves to obtain a mixed solution;

[0029] Step 2. Weigh 0.02g of 1,2,4-triazole, add it into the mixed solution, and dissolve it by ultrasonic treatment at 30°C for 20 minutes. Use hydrochloric acid and sodium hydroxide with a concentration of 1mol / L to adjust the pH of the solution to 5.5, Stir at room temperature for 30 minutes to obtain the treatment solution;

[0030] Step 3. Immerse 5g of cotton fabric in a NaOH solution with a mass fraction of 2% at a bath ratio of 1:50, wash at 80°C, dry after washing, and then immerse the mass fraction at a bath ratio of 1:50 In a 20% sodium chloroacetate solution, react at room temperature for 10 minutes, take it out, wash it, and dry it to obtain a cotton fabric treated with etherification modification;

[0031] Step 4. Put the etherified and modified cotton fabric in step ...

Embodiment 3

[0033] Step 1. Weigh 0.2472g of ammonium molybdate tetrahydrate and 0.1128g of copper nitrate in a beaker, add 50ml of ethanol, and stir at 50°C until it dissolves to obtain a mixed solution;

[0034] Step 2. Weigh 0.0276g of 1,2,4-triazole, add it into the mixed solution, and dissolve it by ultrasonic treatment at 50°C for 20 minutes. Use hydrochloric acid and sodium hydroxide with a concentration of 1mol / L to adjust the pH of the solution to 8.5, stir at room temperature for 30 minutes to obtain the treatment solution;

[0035] Step 3. Immerse 5g of cotton fabric in a NaOH solution with a mass fraction of 2% at a bath ratio of 1:50, wash at 80°C, dry after washing, and then immerse the mass fraction at a bath ratio of 1:100 In a 30% sodium chloroacetate solution, react at room temperature for 20 minutes, take it out, wash it, and dry it to obtain a cotton fabric treated with etherification modification;

[0036] Step 4. Put the etherified cotton fabric in step 3 into the tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com