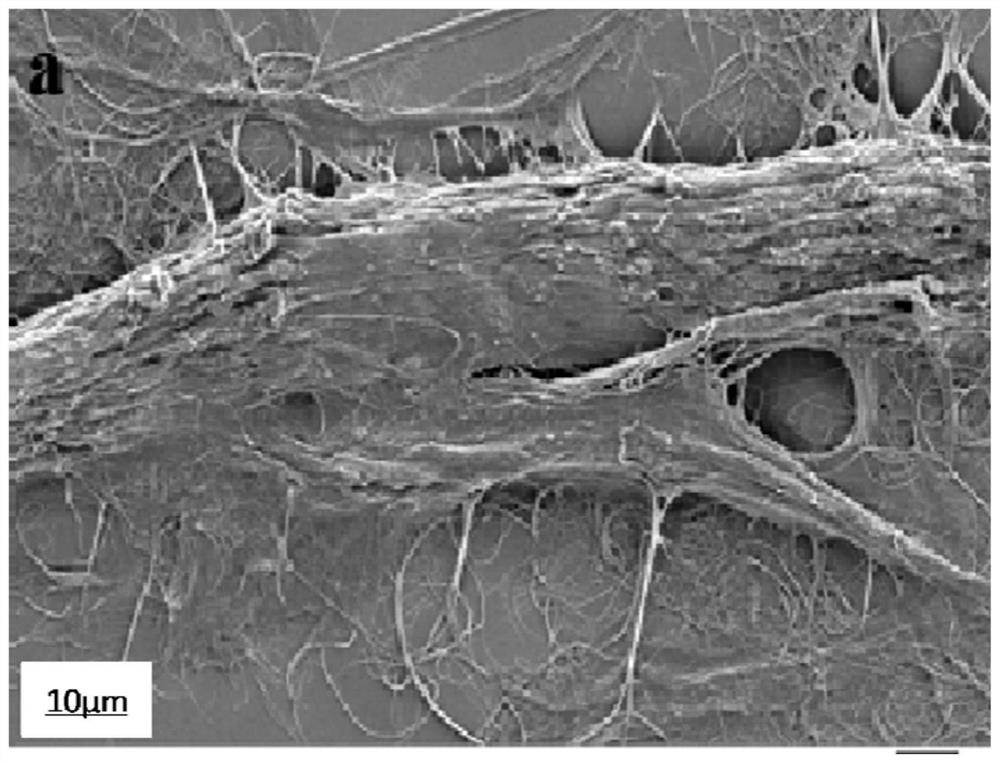

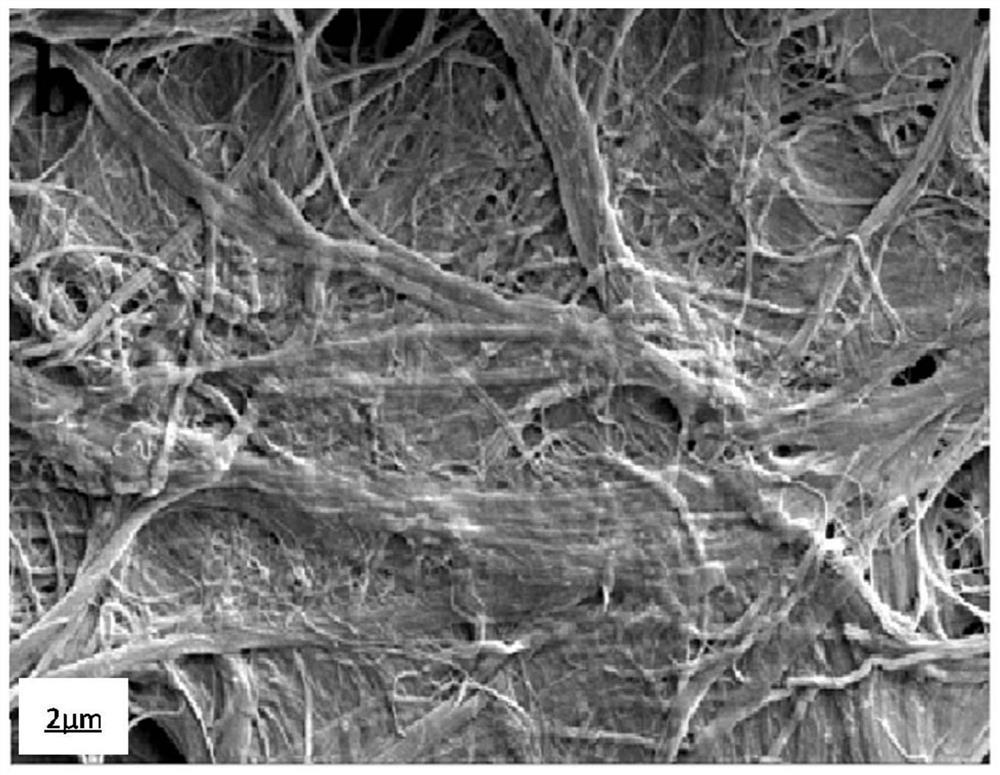

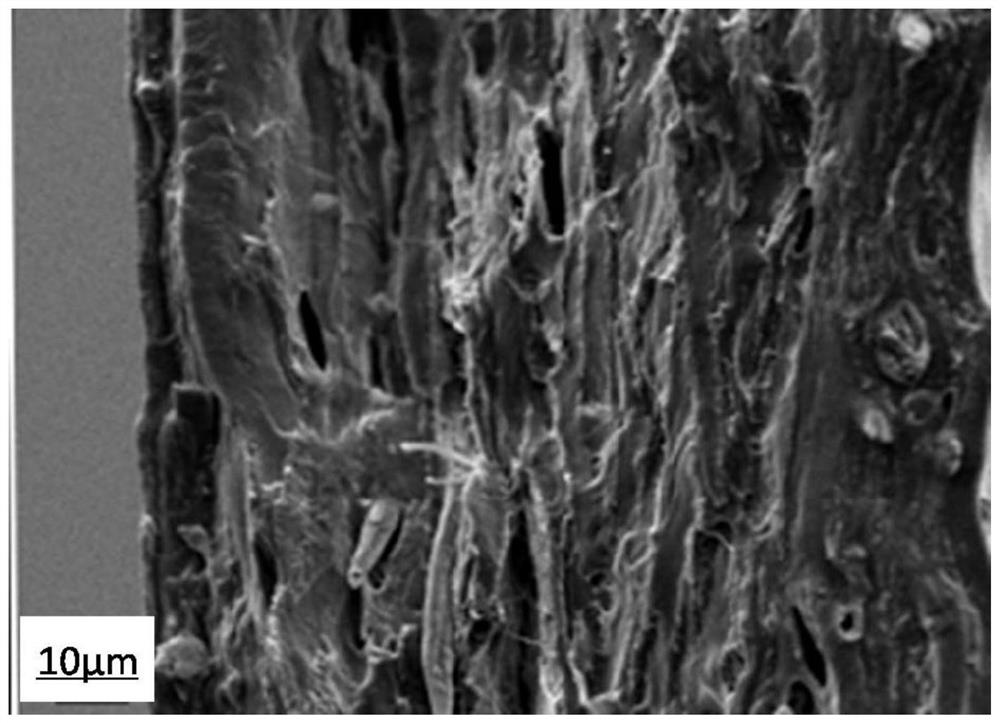

Method for preparing human dura mater repair material with simulated ECM (Extracellular Matrix) component and structure through long fiber network skeleton preforming process

A repair material and long-fiber technology, applied in prosthesis, tissue regeneration, medical science, etc., can solve toxicity and other problems, achieve large tensile strain, ensure biocompatibility, improve toughness and sutureability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] A preparation method of a human dura mater repair material imitating ECM composition and structure, comprising the steps of:

[0069] (1) Soak chitosan long fiber material (length is 2cm) and chitosan short fiber material (length is 3mm) respectively in the moistening liquid (0.5wt% sodium hydroxide solution), carry out pretreatment (water absorption Rinse up for 8 hours), rinse the slurry with deionized water until the pH value of the slurry lotion is neutral, obtain the pretreated chitosan long fiber material and the pretreated chitosan short fiber material; silk long Fiber (length 2cm) and silk short fiber (length 3mm) were soaked in Na 2 CO 3 Solution (mass percentage concentration is 1wt%, silk fiber and Na 2 CO 3 The solid-to-liquid ratio of the solution is 1:5g / mL), and the decollagenization treatment is carried out under stirring (in a water bath, the temperature is 100°C, and the time is 1h), and after the water bath, rinse the fiber with a large amount of d...

Embodiment 2

[0075] A preparation method of a human dura mater repair material imitating ECM composition and structure, comprising the steps of:

[0076] (1) Chitosan long fiber material (length is 3cm) and chitosan short fiber material (length is 4mm) are soaked respectively in moistening liquid (1wt% sodium hydroxide solution), carry out pretreatment (absorbing moisture up 8 hours), rinse the slurry with deionized water until the pH value of the slurry washing solution is neutral, obtain the pretreated chitosan long fiber material and the pretreated chitosan short fiber material; the silk long fiber (length 3cm) and short silk fibers (length 4mm) were soaked in Na 2 CO 3 Solution (mass percentage concentration is 1wt%, silk fiber and Na 2 CO 3The solid-to-liquid ratio of the solution is 1:5), and the decollagenization treatment is carried out in a stirring state (in a water bath state, the temperature is 100 ° C, and the time is 1 h). After the water bath, the fibers are washed with a...

Embodiment 3

[0082] A preparation method of a human dura mater repair material imitating ECM composition and structure, comprising the steps of:

[0083] (1) Soak chitosan long fiber material (length is 4cm) and chitosan short fiber material (length is 3mm) respectively in the moistening liquid (1.5wt% sodium hydroxide solution), carry out pretreatment (water absorption Rinse up for 8 hours), rinse the slurry with deionized water until the pH value of the slurry lotion is neutral, obtain the pretreated chitosan long fiber material and the pretreated chitosan short fiber material; silk long Fiber (length 4cm) and silk short fiber (length 3mm) were soaked in Na 2 CO 3 Solution (mass percentage concentration is 1wt%, silk fiber and Na 2 CO 3 The solid-to-liquid ratio of the solution is 1:5), and the decollagenization treatment is carried out in a stirring state (in a water bath state, the temperature is 100 ° C, and the time is 1 h). After the water bath, the fibers are washed with a large...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com