Graphene-doped flame-retardant material and preparation method thereof

A flame retardant material, graphene technology, applied in the field of flame retardant materials, can solve the problems that affect the mechanical properties and performance of polyurethane materials, it is difficult to inhibit the combustion process of materials, and the flame retardant performance of polyurethane is poor, so as to achieve good mechanical properties and development Effect of small cell size and good flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

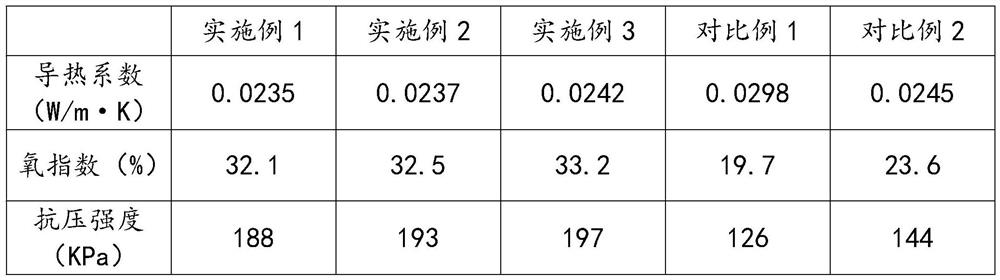

Examples

Embodiment 1

[0035] A flame-retardant material doped with graphene, comprising the following raw materials in parts by weight: 40 parts of polyether polyols, 100 parts of isocyanates, 30 parts of flame retardants, 0.2 parts of catalysts, 5 parts of chain extenders, 2 parts of graphene fillers, 1 part of stabilizer and 2 parts of deionized water;

[0036] This flame retardant material doped with graphene is made by the following steps:

[0037] Step S1: Place the polyether polyol in the weight part of the formula in a vacuum drying oven, and dry it for 2 hours at a temperature of 80° C. to obtain a dried polyether polyol. Put the isocyanate in a vacuum drying oven, drying at 60°C for 3 hours to obtain dry isocyanate;

[0038] Step S2: Place the dry polyether polyol obtained in step S1, flame retardants, catalysts, chain extenders, graphene fillers, stabilizers and deionized water in the mixing tank and mix them in the power Under the conditions of 50W and 20kHz frequency, ultrasonic dispe...

Embodiment 2

[0053] A flame-retardant material doped with graphene, comprising the following raw materials in parts by weight: 50 parts of polyether polyols, 120 parts of isocyanates, 40 parts of flame retardants, 0.6 parts of catalysts, 7 parts of chain extenders, 6 parts of graphene fillers, 3 parts of stabilizer and 3 parts of deionized water;

[0054] This flame retardant material doped with graphene is made by the following steps:

[0055] Step S1: Put the polyether polyol in the weight part of the formula in a vacuum drying oven, and dry it for 4 hours at a temperature of 90°C to obtain a dried polyether polyol, place the isocyanate in a vacuum drying oven, drying at a temperature of 70°C for 4 hours to obtain dry isocyanate;

[0056] Step S2: Place the dry polyether polyol obtained in step S1, flame retardants, catalysts, chain extenders, graphene fillers, stabilizers and deionized water in the mixing tank and mix them in the power Under the conditions of 55W and 20kHz frequency, ...

Embodiment 3

[0071] A flame retardant material doped with graphene, comprising the following raw materials in parts by weight: 60 parts of polyether polyol, 130 parts of isocyanate, 50 parts of flame retardant, 1 part of catalyst, 10 parts of chain extender, 8 parts of graphene filler, 5 parts of stabilizer and 5 parts of deionized water;

[0072] This flame retardant material doped with graphene is made by the following steps:

[0073] Step S1: Put the polyether polyol in the weight part of the formula in a vacuum drying oven, and dry it for 5 hours at a temperature of 100° C. to obtain a dried polyether polyol. Put the isocyanate in a vacuum drying oven, drying at 80°C for 6 hours to obtain dry isocyanate;

[0074]Step S2: Place the dry polyether polyol obtained in step S1, flame retardants, catalysts, chain extenders, graphene fillers, stabilizers and deionized water in the mixing tank and mix them in the power Under the conditions of 60W and 21kHz frequency, ultrasonic dispersion tre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com