Additive-manufactured porous polyetheretherketone scaffold and biological activity improvement method and application thereof

A technology of polyether ether ketone and additive manufacturing, which is applied in tissue regeneration, prosthesis, medical science, etc., and can solve problems such as inability to integrate osseointegration, hinder clinical application of PEEK composite materials, and high brittleness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

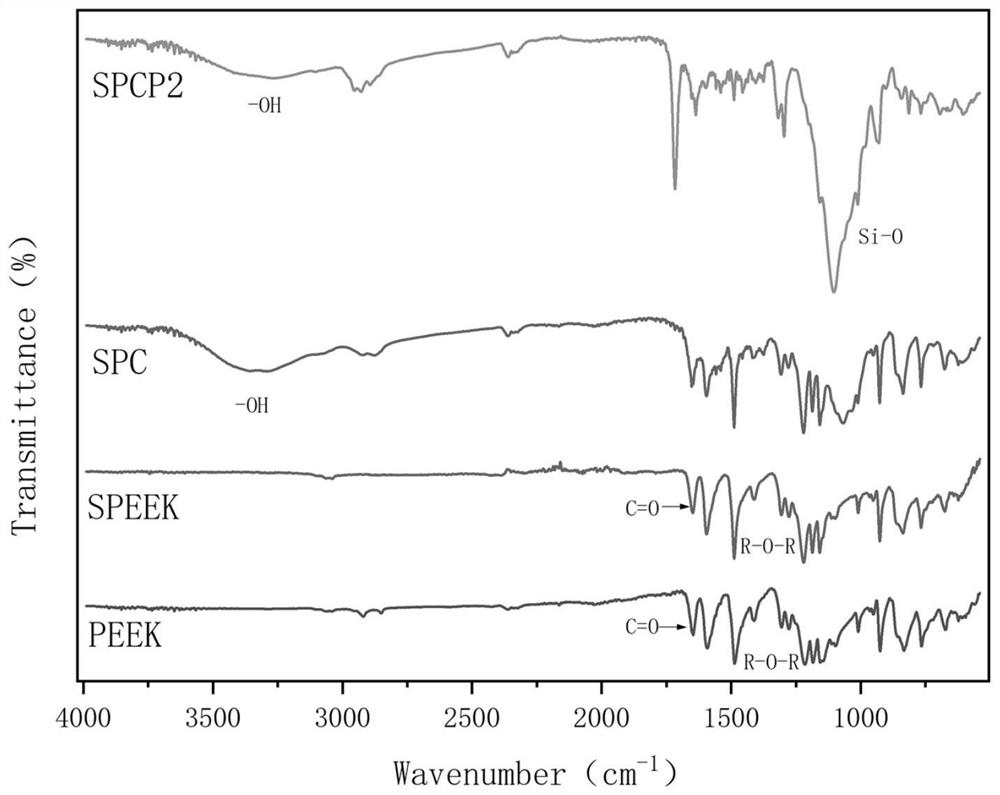

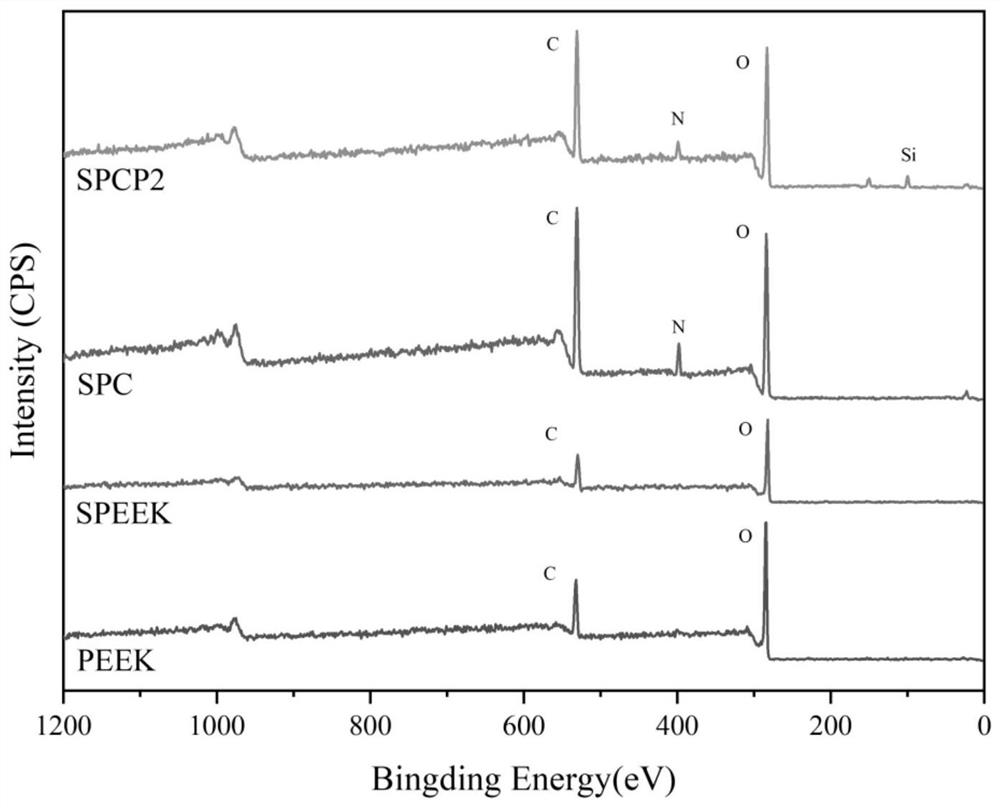

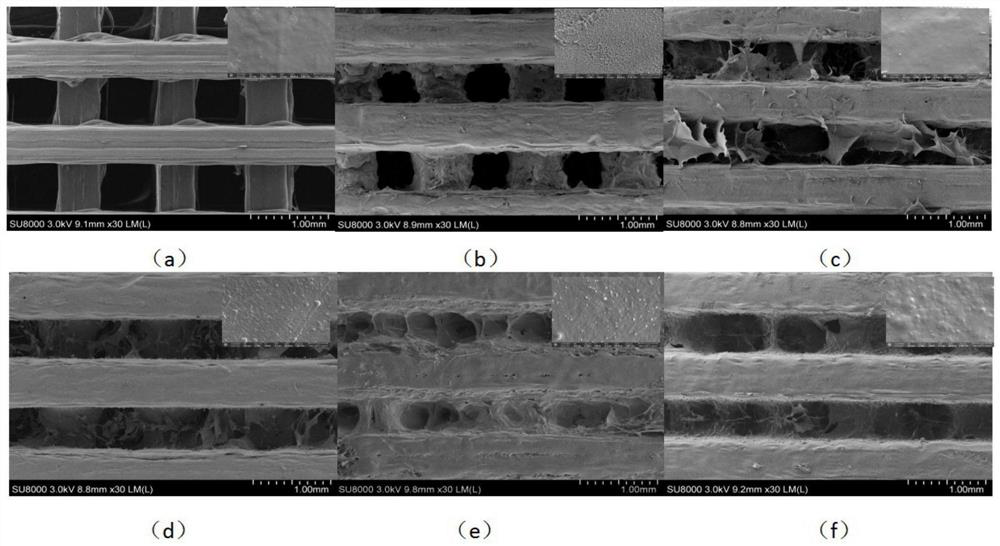

[0049] This embodiment provides a method for improving the bioactivity of a porous polyether ether ketone scaffold manufactured by additive manufacturing, which includes the following steps:

[0050] S1. Design and use CATIA software to model, use FFF system to print a porous polyether ether ketone scaffold with a size of Φ14X3, and perform ultrasonic cleaning for 3 times (each time 30min) with acetone, ethanol, and distilled water, and then place Dry it in a vacuum oven at 60°C and store it for later use to obtain a pretreated additively manufactured porous polyetheretherketone scaffold (named PEEK).

[0051] The specific printing parameters are: the diameter of the print head is 0.4mm, the temperature of the print head is 420°C, the temperature of the bottom plate is room temperature, the temperature of the material box is 65°C, the printing speed is 30mm / min, and the thickness of the printing layer is 0.2mm.

[0052] S2. Submerge the additively manufactured porous polyether...

Embodiment 2

[0066] This embodiment provides a method for improving the bioactivity of a porous polyether ether ketone scaffold manufactured by additive manufacturing, which includes the following steps:

[0067] S1. Design and use CATIA software to model, use FFF system to print a porous polyether ether ketone scaffold with a size of Φ14X3, and perform ultrasonic cleaning for 3 times (each time 30min) with acetone, ethanol, and distilled water, and then place Dry it in a vacuum oven at 50°C and store it for later use to obtain a pretreated additively manufactured porous polyetheretherketone scaffold (named PEEK).

[0068] The specific printing parameters are: the diameter of the print head is 0.4mm, the temperature of the print head is 420°C, the temperature of the bottom plate is room temperature, the temperature of the material box is 65°C, the printing speed is 30mm / min, and the thickness of the printing layer is 0.2mm.

[0069] S2. Submerge the pretreated porous polyether ether ketone...

Embodiment 3

[0076] This embodiment provides a method for improving the bioactivity of a porous polyether ether ketone scaffold manufactured by additive manufacturing, which includes the following steps:

[0077] S1. Design and use CATIA software to model, use FFF system to print a porous polyether ether ketone scaffold with a size of Φ14X3, and perform ultrasonic cleaning for 3 times (each time 30min) with acetone, ethanol, and distilled water, and then place Dry it in a vacuum oven at 70°C and store it for later use to obtain a pretreated additively manufactured porous polyetheretherketone scaffold (named PEEK).

[0078] The specific printing parameters are: the diameter of the print head is 0.4mm, the temperature of the print head is 420°C, the temperature of the bottom plate is room temperature, the temperature of the material box is 65°C, the printing speed is 30mm / min, and the thickness of the printing layer is 0.2mm.

[0079] S2. Submerge the additively manufactured porous polyether...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com