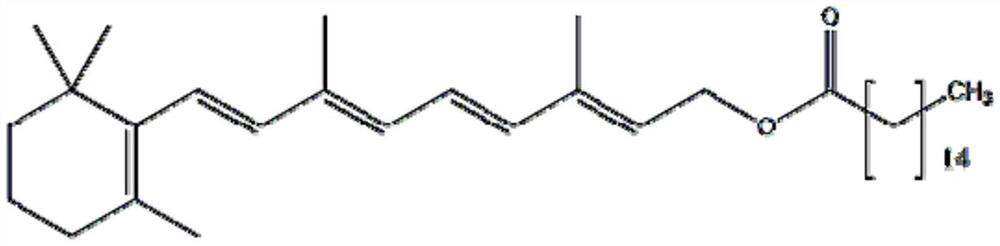

Method for catalytically synthesizing vitamin A palmitate by immobilized enzyme

A technology of palmitate and immobilized enzymes, which is applied in the field of medicine, can solve the problems of short service life of enzyme catalysts, low conversion rate, difficult regeneration, etc., and achieve the effects of many application times, high product conversion rate and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1: VA alcohol preparation

[0027] Accurately weigh 50g (0.147mol) of vitamin A acetate and place it in a 500ml three-necked bottle, add 100ml of methanol to replace the air in the bottle with nitrogen, stir and mix, stir at 100-200rpm, and add sodium hydroxide lye dropwise at 10°C After 0.5 hours, the reaction was completed, extracted with 500ml n-heptane, and washed with water until neutral. The n-heptane extract was detected by HPLC method, and the conversion rate of alcoholysis was 100%.

Embodiment 2

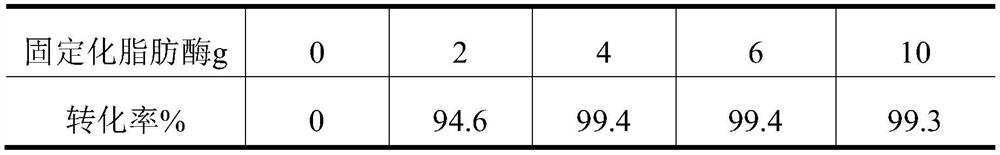

[0028] Embodiment 2: Esterification reaction

[0029] The vitamin A alcohol solution prepared in Example 1 was placed in a 1000ml three-necked bottle, 44g (0.17mol) of palmitic acid was added, and 10g of immobilized lipase (purchased from Novozymes Co. TL IM lipase) The purchased enzyme is silica gel immobilized enzyme, add 600ml n-hexane, replace the air with nitrogen, reflux reaction at 10°C, and remove the water generated in the reaction process, react for 3 hours. The esterification solution was taken and detected by HPLC method, and the conversion rate of esterification was 99.6%.

Embodiment 3

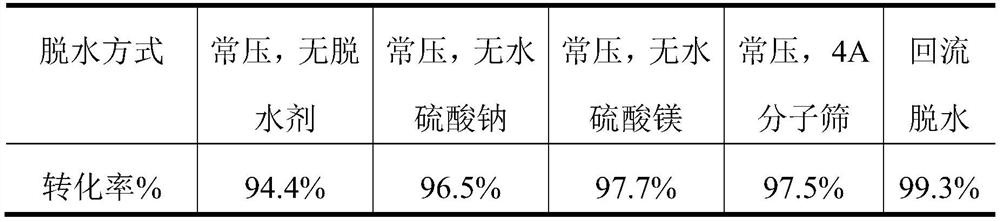

[0031] The operation steps are the same as in Example 2, the difference is that different types of dehydrating agents such as anhydrous sodium sulfate, anhydrous magnesium sulfate, 4A molecular sieve, etc. are added in the normal pressure esterification process, and the effectiveness of different dehydration methods is investigated. The results are shown in Table 1 .

[0032] Table 1

[0033]

PUM

| Property | Measurement | Unit |

|---|---|---|

| esterification rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com