Portable outer formwork, wall body structure and production method of outer formwork

A technology for external formwork and walls, which is applied in the direction of walls, building components, building structures, etc., and can solve the problem of low density of organic particles wrapped in inorganic materials, increase the overall thickness and weight per unit area of the external formwork, and increase the unit area of the external formwork Weight and other issues, to achieve the effect of improving thermal insulation and waterproof effects, light and fast installation, and reducing the difficulty of construction for workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

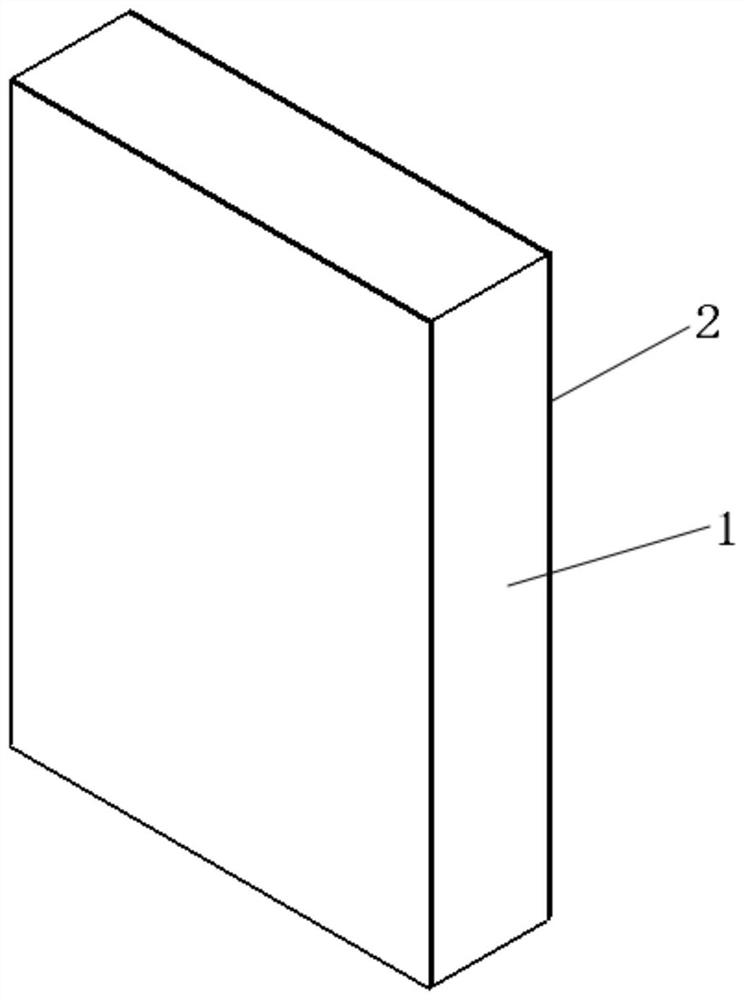

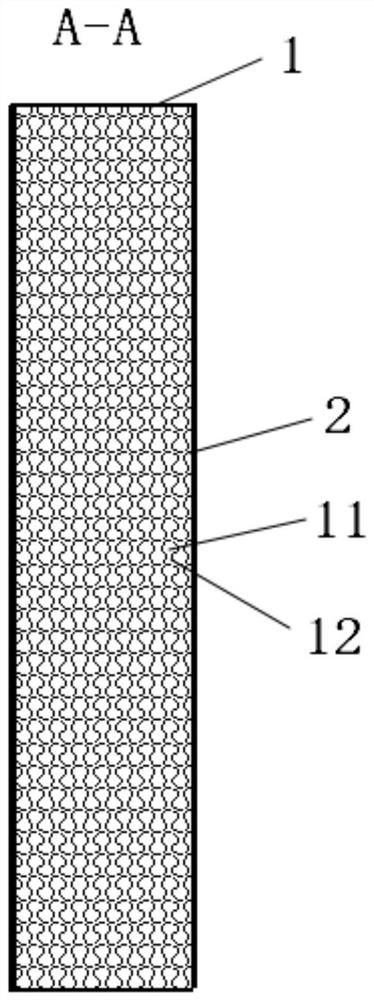

[0034] Such as Figure 1-Figure 3 As shown, this specific embodiment provides a portable external formwork, including a thermal insulation board main body 1, and mesh cloth 2 is arranged on both sides of the thermal insulation board main body 1. In this solution, alkali-resistant glass fiber mesh cloth is preferably used. The mesh cloth 2 described above is directly compounded on the main body 1 of the insulation board to form an integral body. During the manufacturing process, the main body 1 of the insulation board and the mesh cloth 2 are extruded, and the mesh cloth 2 is pressed into the main body 1 of the insulation board. On both sides, the main body 1 of the insulation board is an inorganic material wrapped organic particle board; wherein, the inorganic material 12 in the main body 1 of the insulation board is preferably cement, porous silicon, fly ash or slag powder, and the organic particles in the main body 1 of the insulation board 11 is preferably polystyrene foame...

specific Embodiment approach 2

[0038] Such as Figure 4 As shown, this specific embodiment provides a wall structure, including the outer formwork in the specific embodiment 2, and also includes the base wall 3, the outer formwork is laid on the outside of the base wall 3, and further, the outer The formwork is connected to the base wall 3 through the connector 4 to enhance the firmness of the installation, and the outer formwork is applied to the wall. While meeting the building standards, because it is lighter, it reduces the construction difficulty of the workers and improves the construction efficiency. Efficiency, coupled with its low cost, saves construction and construction costs to a great extent compared to other exterior wall formwork. At the same time, because the outer formwork is thinner, the indoor area can be increased, and the room rate is higher. The overall performance of the wall is better.

specific Embodiment approach 3

[0040] This specific embodiment provides a kind of production method of portable outer formwork described in specific embodiment 1, mainly comprises the following steps:

[0041] A1: Mix and stir the inorganic material 12 and the organic particles 11; mix them evenly, the inorganic material 12 wraps the outer surface of the organic particles 11, and the organic particles 11 are separated.

[0042] A2: Lay grid cloth on both sides of the vertical forming mold, pour the mixed slurry in step A1 between the grid cloths on both sides of the vertical forming mold, Apply pressure from the side and press the mesh cloth into the mixed slurry to form the main body of the insulation board; or, spread the mesh cloth on the bottom of the horizontal forming mold, then pour the mixed slurry in step A1 into the horizontal forming mold, and pour Then spread another mesh cloth on the upper part of the mixed slurry or put it on the pressure-applying mechanism, and use the pressure-applying mecha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com