Preparation method of porous film material for shielding terahertz waves

A porous film, porous foam technology, applied in chemical instruments and methods, inorganic chemistry, coatings, etc., can solve the problems of rough surface of porous film materials, poor toughness, inability to bend, poor electrical conductivity, etc., saving process, The effect of smooth surface and improved yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

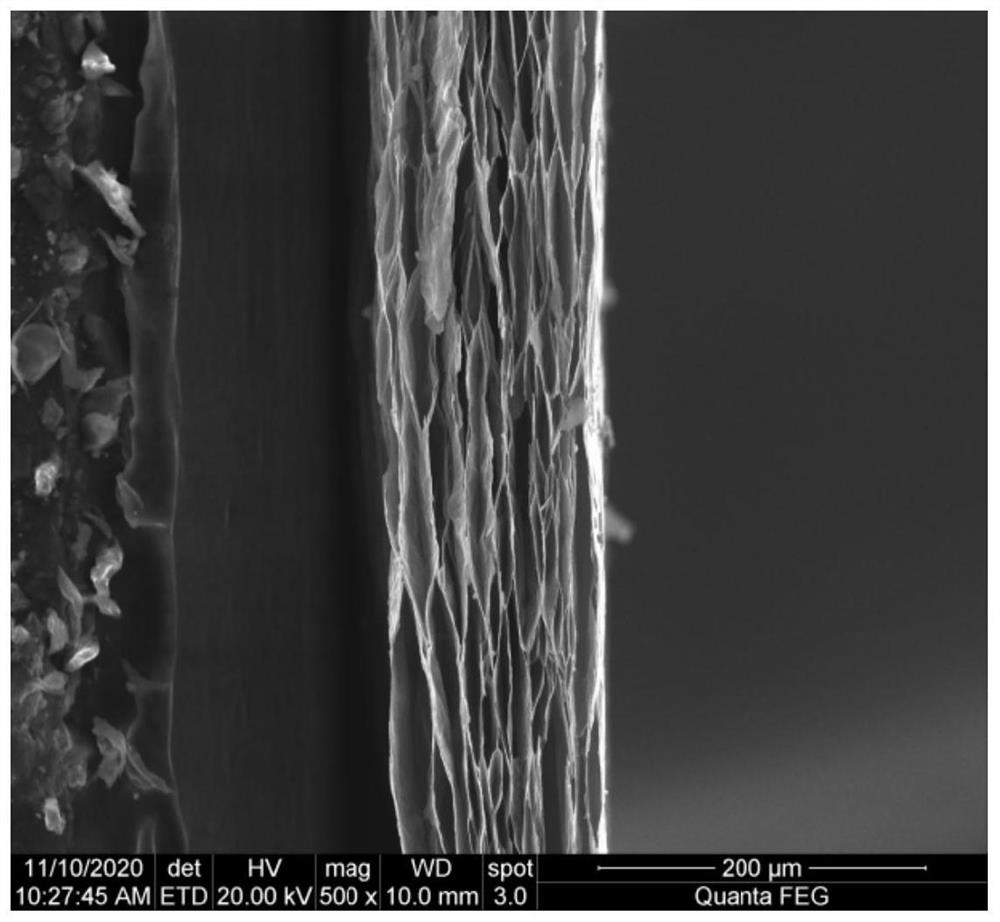

[0027] S1: Transfer 4ml of graphene oxide aqueous solution with a concentration of 10mg / ml to a standard glass slide placed horizontally. After natural drying, the thickness of the film is about 20 μm. Cut the slide into two identical pieces.

[0028] S2: Place the graphene oxide film in S1 in sequence with gaskets, porous nickel mesh, and glass slides and fix them with rubber bands. The thickness of the porous nickel mesh is 0.5-1mm, the pore diameter is 50-110ppi, and the porosity is greater than or equal to 95. %, the through-hole rate is greater than or equal to 95%, indicating smoothness.

[0029] S3, putting the fixed graphene oxide film in S2 into a sealable container with hydrazine hydrate, so that it is above the hydrazine hydrate and not in contact, then put the sealed container into a water bath and heat for 3 hours to obtain Graphene porous film.

[0030] S4. Put the graphene porous film obtained in S3 into a tube furnace for heat treatment, the treatment atmosphe...

Embodiment 2

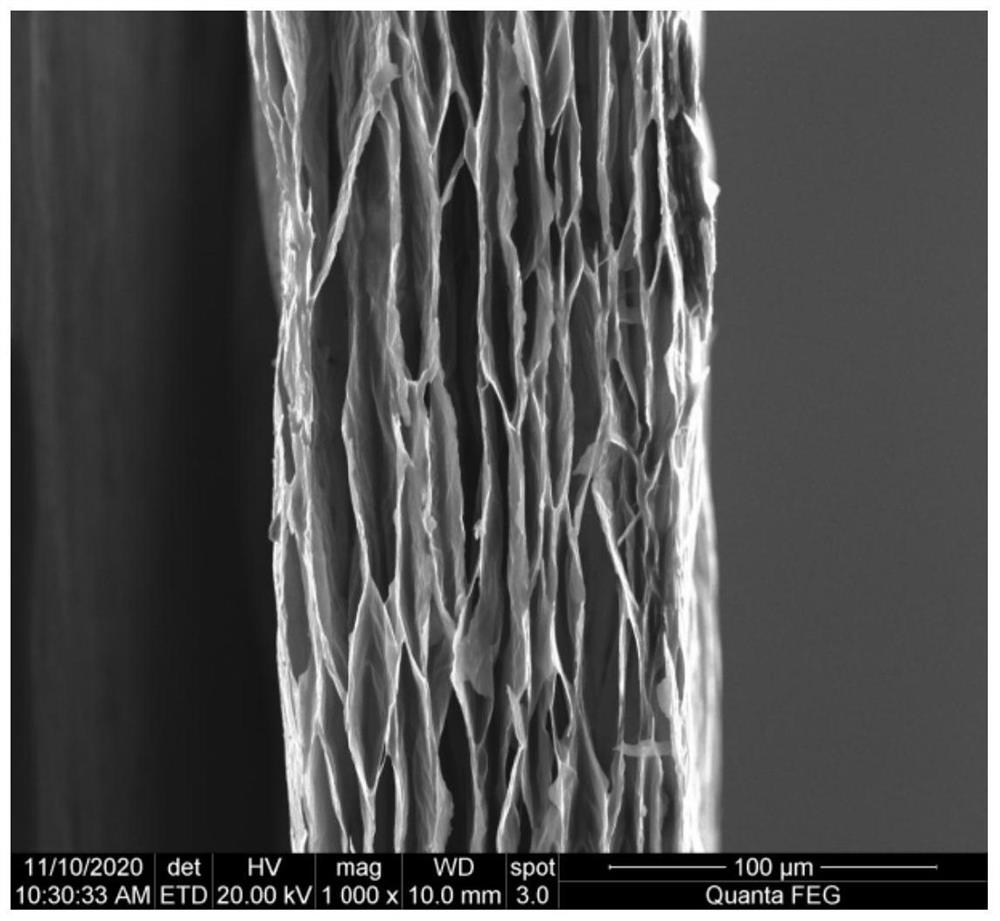

[0033] S1. Transfer 4ml of graphene oxide aqueous solution with a concentration of 10mg / ml to a standard glass slide placed horizontally. After natural drying, the thickness of the film is about 20 μm. Cut the glass slide into two identical pieces.

[0034] S2: Place the graphene oxide film in S1 in sequence with gaskets, porous nickel mesh, and glass slides and fix them with rubber bands. The thickness of the porous nickel mesh is 0.5-1mm, the pore diameter is 50-110ppi, and the porosity is greater than or equal to 95. %, the through-hole rate is greater than or equal to 95%, indicating smoothness.

[0035] S3, putting the fixed graphene oxide film in S2 into a sealable container with hydrazine hydrate, so that it is above the hydrazine hydrate and not in contact, then put the sealed container into a water bath and heat for 3 hours to obtain Graphene porous film.

[0036] S4. Put the graphene porous film obtained in S3 into a tube furnace for heat treatment, the treatment at...

Embodiment 3

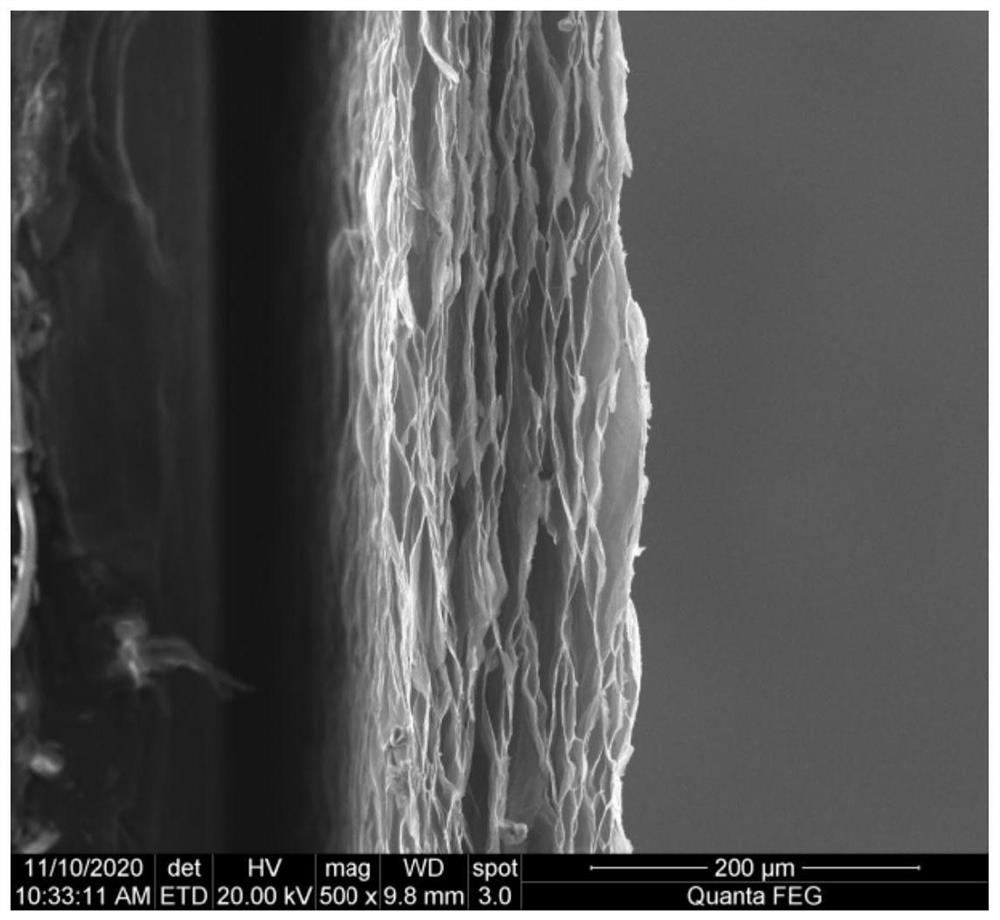

[0039] S1. Transfer 4ml of graphene oxide aqueous solution with a concentration of 10mg / ml to a standard glass slide placed horizontally. After natural drying, the thickness of the film is about 20 μm. Cut the glass slide into two identical pieces.

[0040] S2: Place the graphene oxide film in S1 in sequence with gaskets, porous nickel mesh, and glass slides and fix them with rubber bands. The thickness of the porous nickel mesh is 0.5-1mm, the pore diameter is 50-110ppi, and the porosity is greater than or equal to 95. %, the through-hole rate is greater than or equal to 95%, indicating smoothness.

[0041] S3, putting the fixed graphene oxide film in S2 into a sealable container with hydrazine hydrate, so that it is above the hydrazine hydrate and not in contact, then put the sealed container into a water bath and heat for 3 hours to obtain Graphene porous film.

[0042] S4. Put the graphene porous film obtained in S3 into a tube furnace for heat treatment, the treatment at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com