Remodeling method of polystyrene plastic granules

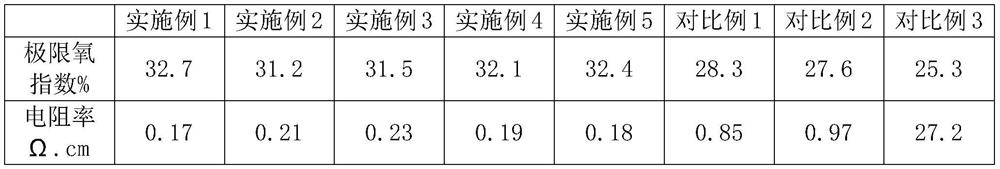

A technology of polystyrene plastic and polystyrene, which is applied in the field of remolding polystyrene plastic particles, can solve the problems of single function, low quality polystyrene, and long time-consuming, etc., and achieve simple processing technology and good flame retardancy Performance, the effect of improving the resistivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A method for remodeling polystyrene plastic particles, comprising the following steps:

[0029] a. Remove the dirt adhering to the surface of the pre-remodeled polystyrene foam to make the volume ≤ 1cm 3 block material;

[0030] b. Place the prepared block in a water-insoluble organic solvent to dissolve it into a polystyrene swelling body; the organic solvent is benzene;

[0031] c. Put the polystyrene swelling body in room temperature water containing sodium dodecylbenzenesulfonate with a concentration of 2.8g / L, heat while stirring, control the stirring speed at 250rpm, heat to 75°C, stop heating and keep the constant temperature for 45min. The heating rate is controlled at 0.8°C / min;

[0032] d. Solid-liquid separation is carried out by filtration, and the separated solid particles are dried into translucent white polystyrene particles with a particle size of about 1mm;

[0033] e, then soak the solid polystyrene particles in the foaming agent, and soak for 12 ho...

Embodiment 2

[0050] A method for remodeling polystyrene plastic particles, comprising the following steps:

[0051] a. Remove the dirt adhering to the surface of the pre-remodeled polystyrene foam to make the volume ≤ 1cm 3 block material;

[0052] b. Place the prepared block in a water-insoluble organic solvent to dissolve it into a polystyrene swelling body; the organic solvent is benzene, toluene, xylene or chloroform;

[0053] c. Put the polystyrene swelling body in room temperature water containing sodium dodecylbenzenesulfonate with a concentration of 3.0g / L, heat while stirring, control the stirring speed at 200rpm, heat to 80°C, stop heating and keep the constant temperature for 30min. The heating rate is controlled at 1°C / min;

[0054] d. Solid-liquid separation is carried out by filtration, and the separated solid particles are dried into translucent white polystyrene particles with a particle size of about 1mm;

[0055] e, then soak the solid polystyrene particles in the foam...

Embodiment 3

[0071] A method for remodeling polystyrene plastic particles, comprising the following steps:

[0072] a. Remove the dirt adhering to the surface of the pre-remodeled polystyrene foam to make the volume ≤ 1cm 3 block material;

[0073] b. Place the prepared block in a water-insoluble organic solvent to dissolve it into a polystyrene swelling body; the organic solvent is chloroform;

[0074] c. Put the polystyrene swelling body in room temperature water containing sodium dodecylbenzenesulfonate with a concentration of 2.4g / L, heat while stirring, control the stirring speed at 300rpm, heat to 70°C, stop heating and keep the constant temperature for 50min, The heating rate is controlled at 0.5°C / min;

[0075] d. Solid-liquid separation is carried out by filtration, and the separated solid particles are dried into translucent white polystyrene particles with a particle size of about 1mm;

[0076] e, then soak the solid polystyrene particles in the foaming agent, and soak for 13...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com