Extraction method of leek green pigment, sodium copper chlorophyllin and sodium zinc chlorophyllin prepared by using the method, and stability comparison

A technology of sodium copper chlorophyllin and zinc sodium chlorophyll, which is applied in the field of extraction of green pigment from leeks, can solve the problems of less stability, browning, and fading of natural green pigment, and achieve stable coloring effect, good coloring effect, and extraction and preparation process simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

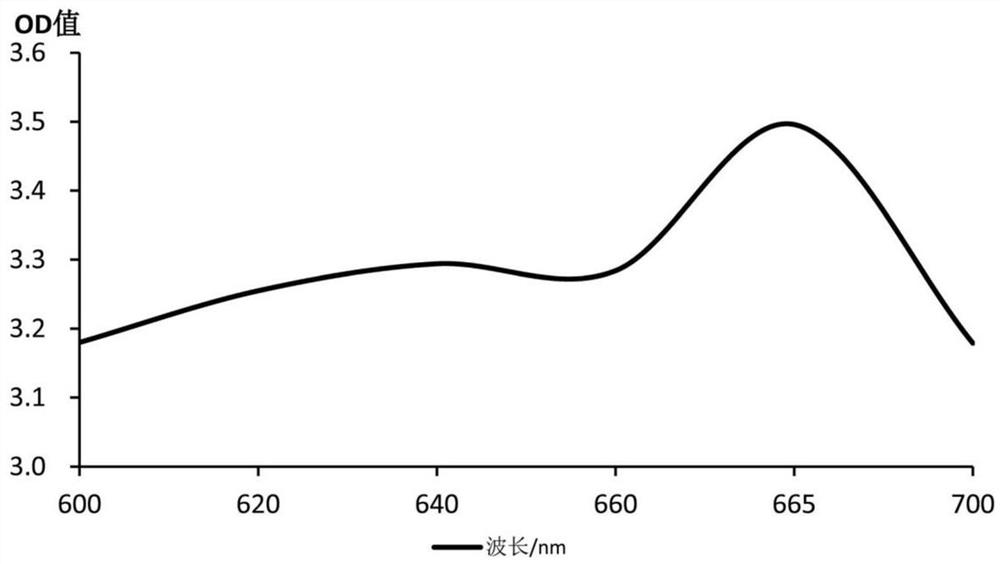

Image

Examples

Embodiment 1

[0053] A method for extracting leek green pigment, characterized in that it comprises the following steps:

[0054] Step 1. Remove the yellow leaves on the leeks, wash them, cut them into sections, then put them into a vacuum freeze dryer to freeze-dry, then crush them with a pulverizer, pass through a 40-60 mesh sieve, and store them at low temperature in a dark place for later use;

[0055] Step 2, weigh 10g of leek powder or directly take the washed fresh leek and homogenize it with a homogenizer in a ratio of 1:1;

[0056] Step 3: Add the aqueous solution containing 0.3% cellulase and 0.1% pectinase compound enzyme at the ratio of solid to liquid ratio of 1:4, use salicylic acid to adjust the pH value of the environment to 4.8, and bathe in water at 45°C for 60 minutes , treated under the condition of microwave power of 600W for 60S, filtered to remove the supernatant, and collected the filter residue A for later use;

[0057] Step 4, adding the edible ethanol whose volum...

Embodiment 2

[0066] A method for preparing sodium copper chlorophyllin, comprising the following steps:

[0067] S1: Saponification; pour the fat-soluble green pigment mainly composed of chlorophyll into a beaker, use 10% NaOH to adjust the pH to 12-13, and saponify 30- 40min;

[0068] S2: Complete saponification; take it out after saponification, then cool to room temperature, filter to remove unsaponifiable viscous impurities, then transfer the saponified liquid into a separatory funnel and add petroleum ether equal to the volume of the saponified liquid, then fully shake and stand still After stratification, the upper layer is yellow and is completely saponified;

[0069] S3: Acidify copper; put the extract from the lower layer of the separating funnel in S2 into a beaker, adjust the pH value to 1.5-2.0 with 10% HCl, add acid to make it fully react, the solution turns yellowish brown and generates magnesia green acid;

[0070] Detect the content of magnesium ions;

[0071] Add 10% c...

Embodiment 3

[0080] A method for preparing chlorophyll zinc sodium salt, is characterized in that, comprises the following steps:

[0081] a: the concentration of 10ml leaching is 1g / ml and the fat-soluble green pigment based on chlorophyll is placed in a round bottom flask;

[0082] b: Saponification; add 10% NaOH to adjust the pH to 12-13, the saponification temperature is 60°C, the saponification time is 30min, and the ultrasonic power is 200W;

[0083] c: extraction; according to the condition of 1:1, add petroleum ether to the cooled saponified liquid, let it stand for several hours to separate, the lower layer is dark green saponified liquid;

[0084] d: acidification; use 10% HCl to adjust the pH to 2-3 after collecting the dark green lower layer;

[0085] e: Substitute zinc; add the acidizing solution to the zinc sulfate solution at a ratio of liquid to material of 1:1, the ultrasonic temperature is 70°C, the ultrasonic time is 1h, the ultrasonic power is 200W, and the chlorophyll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com