Aluminum ion cross-linked MXene-ascorbic acid membrane and preparation method thereof

A technology of ascorbic acid and aluminum ions, applied in chemical instruments and methods, membranes, membrane technology, etc., can solve the problems of easy oxidation, easy swelling of MXene membranes, etc., and achieve high removal rate, good promotion, high stability and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

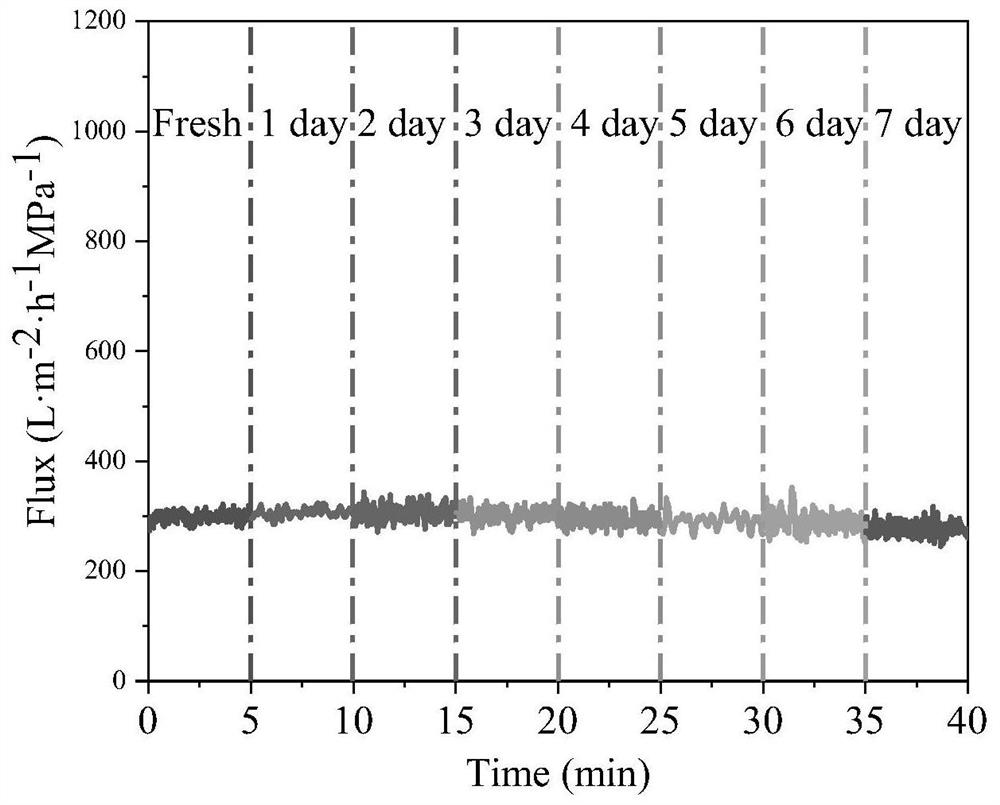

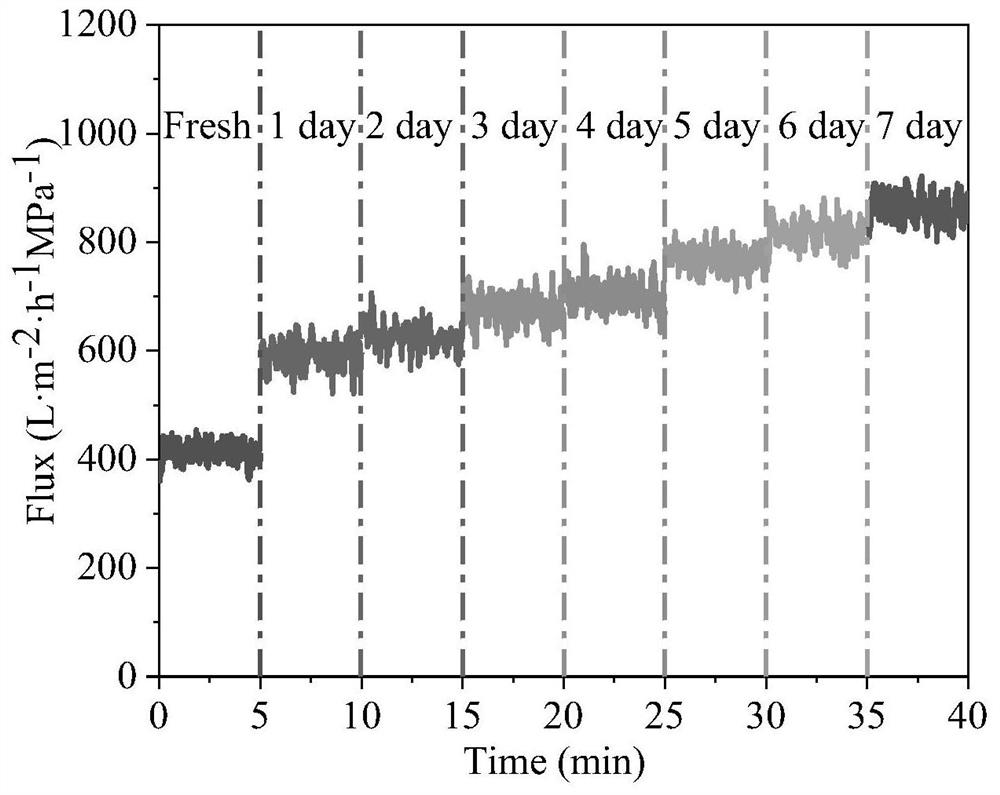

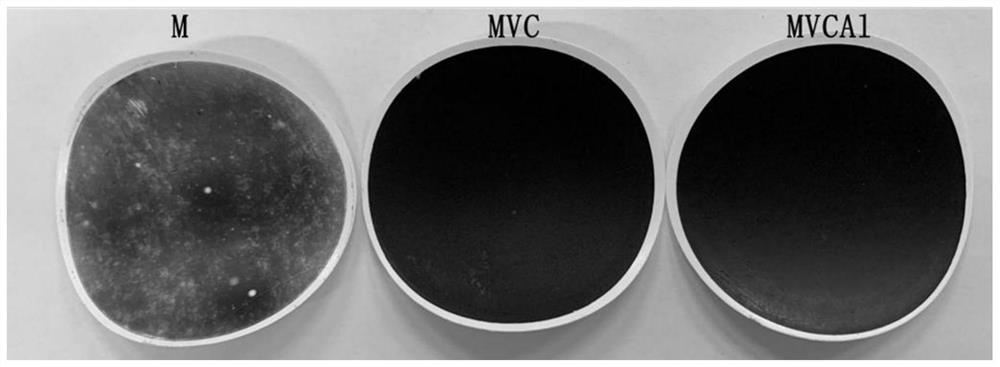

[0041] Step 1: Mix 2g LiF and 40mL of 9mol / L hydrochloric acid in a polytetrafluoroethylene test tube and sonicate for 30min, and mix 2g of 400 mesh Ti 3 AlC 2 Added to the mixed solution of HCl-LiF, reacted at 40°C for 24h, then shaken under argon atmosphere for 1h and centrifuged at 4000rpm for 1h, and obtained single-layer MXene nanosheets in the supernatant;

[0042] Step 2: Prepare a 1 mg / mL MXene solution by adding deionized water to the monolayer MXene nanosheets, then add 1.0 mmol / L ascorbic acid and stir in an argon atmosphere for 24 hours to obtain a mixed solution of MXene-ascorbic acid;

[0043] Step 3: Add 10mL of 1.0mg / mL MXene-ascorbic acid mixed solution into 40mL of deionized water, carry out dead-end filtration in an ultrafiltration cup with a nitrogen pressure of 0.1MPa, and load MXene-ascorbic acid onto 100kd polyethersulfone ( PES) film surface, obtain MXene-ascorbic acid film (MVC);

[0044] Step 4: Soak the MXene-ascorbic acid membrane in a 0.2 mol / L a...

Embodiment 2

[0063] Step 1: Mix 2g of LiF and 31mL of 9mol / L hydrochloric acid in a polytetrafluoroethylene test tube and sonicate for 30min, and 2g of 300 mesh Ti 3 AlC 2 Added to the mixed solution of HCl-LiF, reacted at 30°C for 30h, then shaken under argon atmosphere for 1h and centrifuged at 4000rpm for 1h, and obtained single-layer MXene nanosheets in the supernatant;

[0064] Step 2: Prepare a 1 mg / mL MXene solution by adding deionized water to the single-layer MXene nanosheets, then add 0.1 mmol / L ascorbic acid and stir in an argon atmosphere for 12 hours to obtain a mixed solution of MXene-ascorbic acid;

[0065] Step 3: Add 10mL of 1.0mg / mL MXene-ascorbic acid mixed solution into 40mL of deionized water, carry out dead-end filtration in an ultrafiltration cup with a nitrogen pressure of 0.1MPa, and load MXene-ascorbic acid onto 100kd polyethersulfone ( PES) film surface, obtain MXene-ascorbic acid film (MVC);

[0066] Step 4: Soak the MXene-ascorbic acid membrane in a 0.1 mol / L...

Embodiment 3

[0068] Step 1: Mix 2g LiF and 48mL of 9mol / L hydrochloric acid in a polytetrafluoroethylene test tube and sonicate for 30min, and 2g 500 mesh Ti 3 AlC 2 Added to the mixed solution of HCl-LiF, reacted at 35°C for 48h, then shaken under argon atmosphere for 1h and centrifuged at 4000rpm for 1h, and obtained single-layer MXene nanosheets in the supernatant;

[0069] Step 2: Prepare a 1 mg / mL MXene solution by adding deionized water to the single-layer MXene nanosheets, then add 10 mmol / L ascorbic acid and stir in an argon atmosphere for 48 hours to obtain a MXene-ascorbic acid mixed solution;

[0070] Step 3: Add 10mL of 1.0mg / mL MXene-ascorbic acid mixed solution into 40mL of deionized water, carry out dead-end filtration in an ultrafiltration cup with a nitrogen pressure of 0.1MPa, and load MXene-ascorbic acid onto 100kd polyethersulfone ( PES) film surface, obtain MXene-ascorbic acid film (MVC);

[0071] Step 4: Soak the MXene-ascorbic acid membrane in a 1mol / L aluminum chl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com