Co-doped modified pyrochlore thermal-barrier coating material with ultralow thermal conductivity and preparation method of co-doped modified pyrochlore thermal-barrier coating material

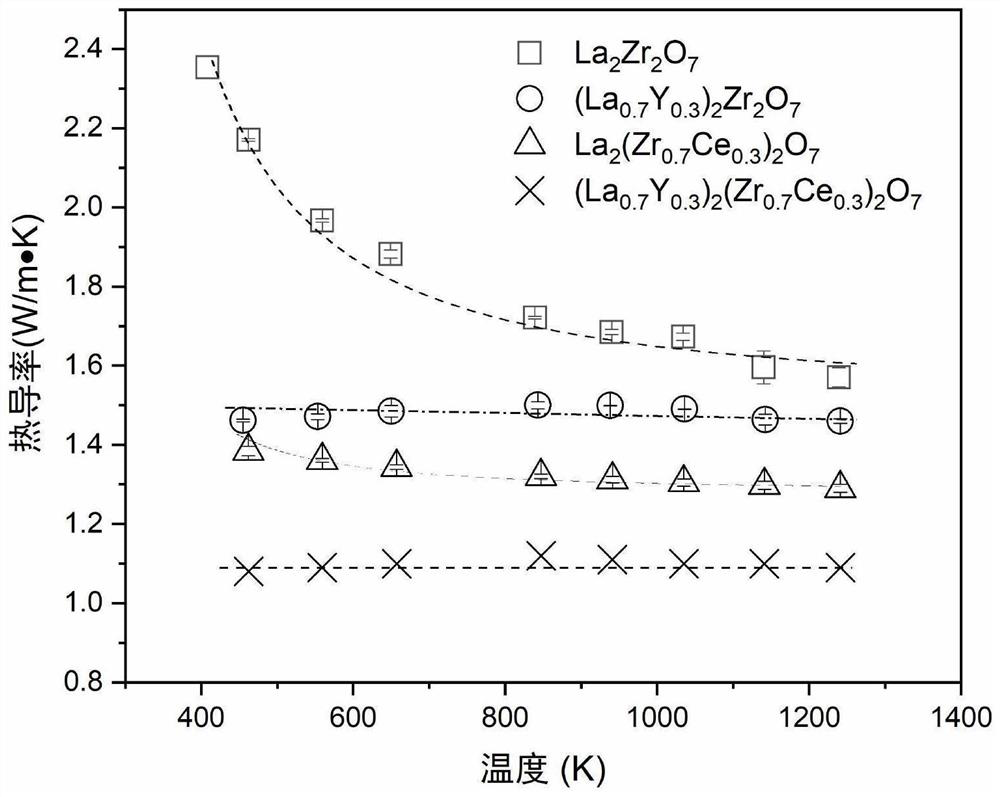

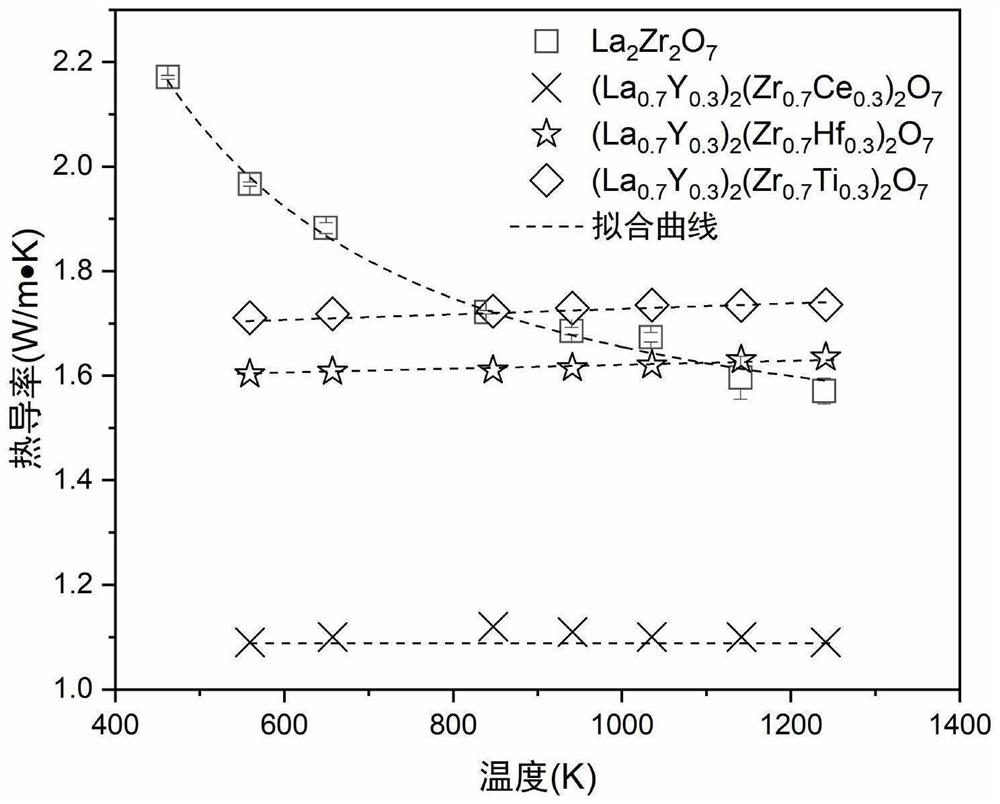

A technology of thermal barrier coating and thermal conductivity, which is applied in the field of ultra-low thermal conductivity co-doped modified pyrochlore thermal barrier coating material and its preparation, which can solve the problem that it is difficult to meet the application requirements and should not exceed 1200 °C, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A low thermal conductivity Y- and Ce-co-doped modified La 2 Zr 2 o 7 Pyrochlore ((La 1-x Y x ) 2 (Zr 1-y Ce y ) 2 o 7 , x=y=0.1) the preparation method of solid solution, comprises the following steps:

[0038] (1) Use Y with a particle size of not more than 10 μm 2 o 3 ,La 2 o 3 ,ZrO 2 ,CeO 2 The powder is weighed according to the preset ratio, and then it is ball milled in a high-energy ball mill tank with distilled water as a medium at a speed of 400r / min for 24 hours. The obtained powder slurry is freeze-dried and calcined at 1500°C for 24 hours, so that the The oxides react fully to form the desired components (La 0.9 Y 0.1 ) 2 (Zr 0.9 Ce 0.1 ) 2 o 7 ;

[0039] (2) The obtained components are fully crushed in a mortar, and then ball milled with distilled water as a medium at a speed of 400r / min for 24 hours, and the obtained slurry is freeze-dried to obtain a well-dispersed powder;

[0040] (3) The finally obtained powder is formed by cold pr...

Embodiment 2

[0042] A low thermal conductivity Y- and Ce-co-doped modified La 2 Zr 2 o 7 Pyrochlore (La 1-x Y x ) 2 (Zr 1-y Ce y ) 2 o 7 The preparation method of solid solution, get x=0.2, y=0.3, other are the same as implementation 1.

Embodiment 3

[0044] A low thermal conductivity Y- and Ce-co-doped modified La 2 Zr 2 o 7 Pyrochlore (La 1-x Y x ) 2 (Zr 1-y Ce y ) 2 o 7 For the preparation method of solid solution, get x=y=0.3, and others are the same as implementation 1.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap