Hollow bowl-shaped nitrogen-doped cobalt/carbon composite material, preparation method and application

A technology of carbon composite materials and hollow bowls, applied in chemical instruments and methods, and other chemical processes, to achieve the effects of expanding the wave-absorbing frequency band, increasing electronic polarization, and improving conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

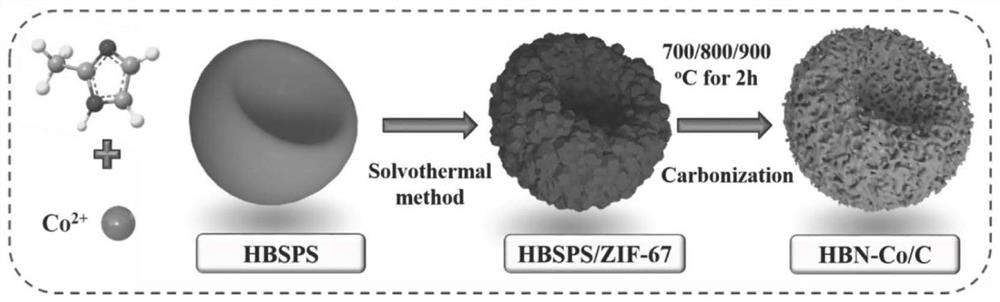

[0038] A kind of preparation method of hollow bowl-shaped nitrogen-doped cobalt / carbon composite material, see figure 1 shown, including the following steps:

[0039] Preparation of hollow bowl-shaped sulfonated polystyrene microspheres (SPS)

[0040] Take an appropriate amount of hollow polystyrene microsphere suspension and place it in an open beaker, and place it in the air. Using the difference between the capillary force generated by the solvent volatilization and the internal and external stress, the surface of the polystyrene microsphere is gradually depressed into a bowl shape. After the solvent is all volatilized, white hollow bowl-shaped polystyrene microspheres are formed; the polystyrene microspheres and concentrated sulfuric acid with a mass ratio of 1:17 are placed in a round-bottomed flask, placed on a magnetic stirrer, and the set temperature is 40°C, the rotation speed is 900 rpm, the purpose is to sulfonate polystyrene microspheres, react for half an hour, c...

Embodiment 2

[0048] Same as Example 1, the difference is:

[0049] Preparation of hollow bowl-shaped nitrogen-doped cobalt / carbon composites

[0050] Take 0.5 g of the above-prepared precursor and place it in a muffle furnace, blow nitrogen into it, set the heating rate at 2°C per minute, keep it at 800°C for two hours, and then drop it to 400°C at a cooling rate of 5°C per minute After cooling down to room temperature naturally, a hollow bowl-shaped nitrogen-doped cobalt / carbon composite material (HBN-Co / C-800) is obtained.

Embodiment 3

[0052] Same as Example 1, the difference is:

[0053] Preparation of hollow bowl-shaped nitrogen-doped cobalt / carbon composites

[0054] Take 0.5 g of the above-prepared precursor and place it in a muffle furnace, blow nitrogen into it, set the heating rate at 2°C per minute, keep it at 900°C for two hours, and then drop it to 400°C at a cooling rate of 5°C per minute After cooling down to room temperature naturally, a hollow bowl-shaped nitrogen-doped cobalt / carbon composite material (HBN-Co / C-900) is obtained.

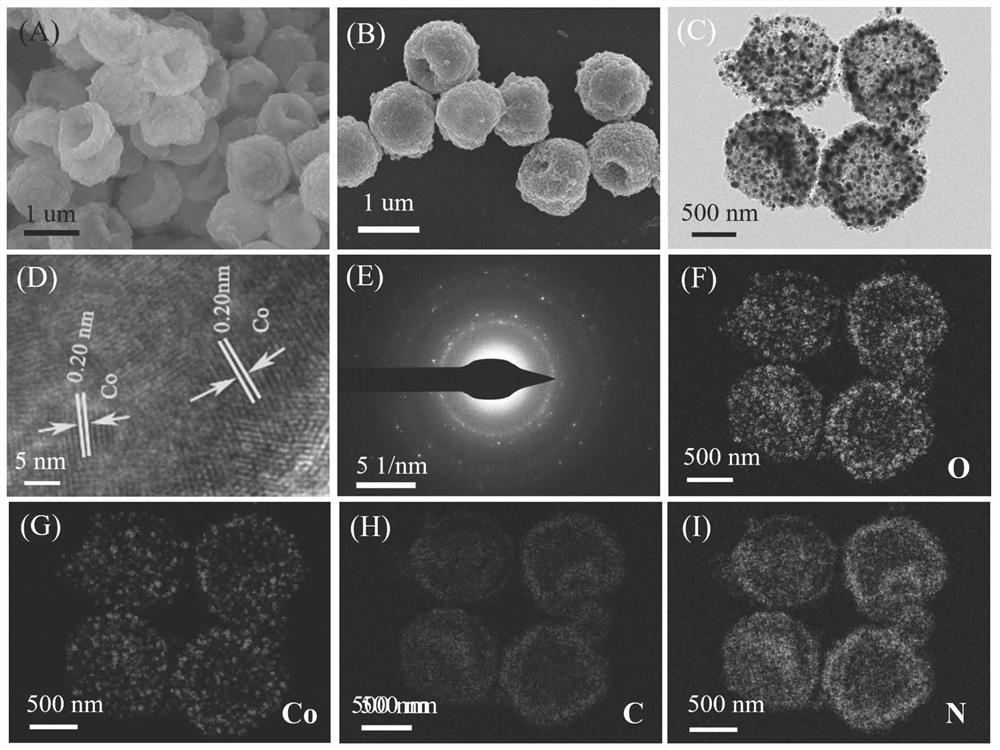

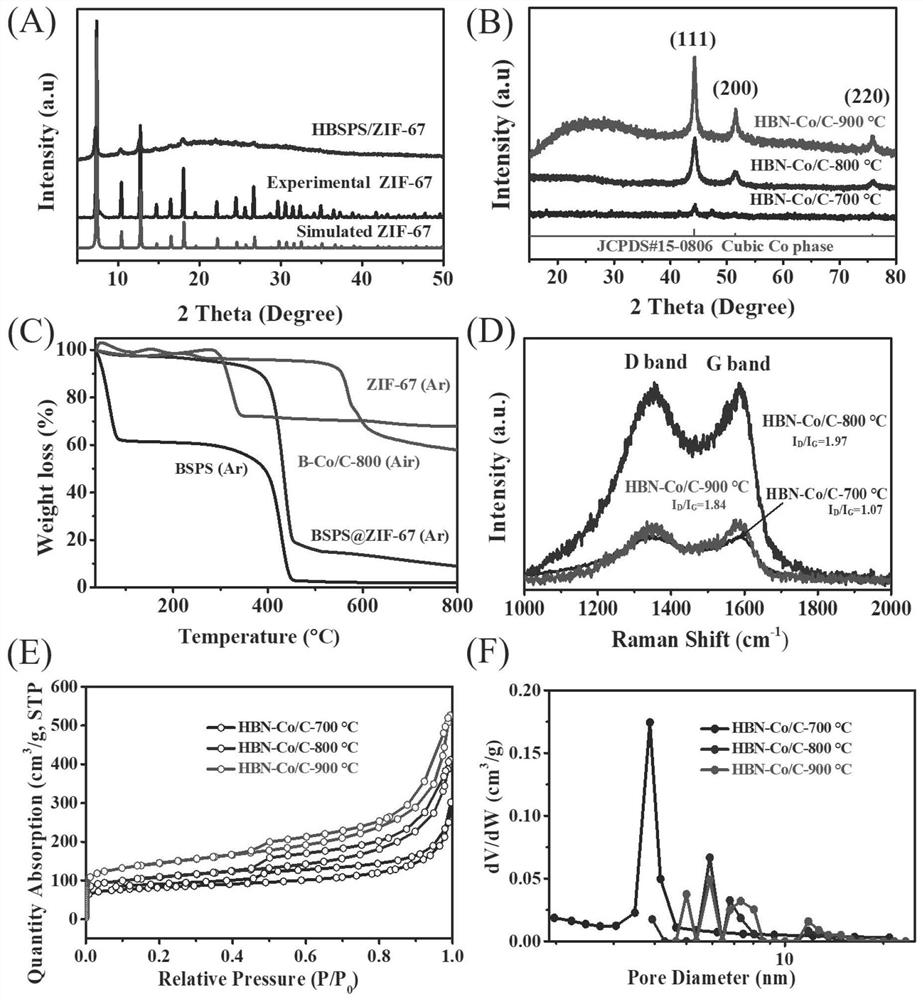

[0055] In order to illustrate the properties of the hollow bowl-shaped nitrogen-doped cobalt / carbon composite material prepared by the preparation method provided by the present invention, X-ray Diffraction (XRD), X-ray photoelectron spectroscopy (XPS), Raman (Raman), specific surface area (BET), electromagnetic wave absorption performance and other instruments for testing and characterization, see Figure 2-6 .

[0056] When testing the electromagnetic parameters...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| absorption bandwidth | aaaaa | aaaaa |

| absorption bandwidth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com