Rare earth doped carbon nanotube/polyvinyl chloride composite wave-absorbing film material

A polyvinyl chloride and carbon nanotube technology, applied in other chemical processes, chemical instruments and methods, etc., can solve the problems of single peak value and narrow absorption bandwidth, and achieve the effect of strong absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

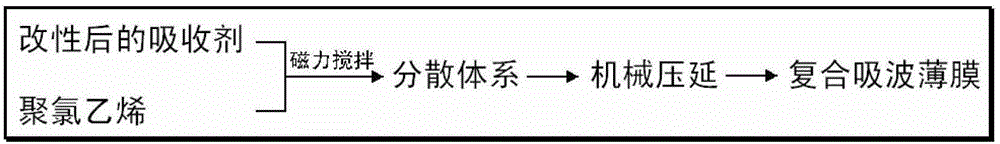

[0032] The process flow is attached figure 1 .

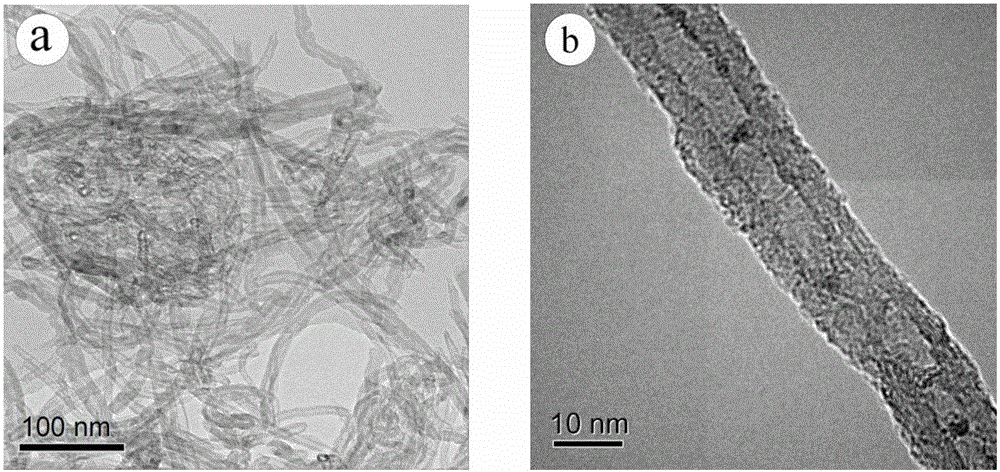

[0033] The process flow is attached figure 1 , using the temperature-controlled arc method to prepare multi-walled carbon nanotubes with a diameter ranging from 7 to 50 nm. After pretreatment such as rare earth (lanthanum nitrate) doping, it is used as an absorber for composite wave-absorbing films; DOP is used as a plasticizer and styrene is used as a crosslinking agent to establish a uniform and stable nanocomposite dispersion system; it is prepared by mechanical calendering technology Resin composite films based on multi-walled carbon nanotubes.

[0034] The specific steps for preparing the composite wave-absorbing film are as follows:

[0035]Step 1: mixing lanthanum nitrate with acidified carbon nanotubes, then ultrasonic and ball milling; the addition of the lanthanum nitrate is less than 1wt.% of the acidified carbon nanotubes;

[0036] Step 2: Weighing a certain amount of polyvinyl chloride and dissolving it in an or...

Embodiment 2

[0041] : Step 1: lanthanum nitrate is mixed with acidified carbon nanotubes, then ultrasonic and ball milled; the addition of said lanthanum nitrate is less than 5wt.% of acidified carbon nanotubes;

[0042] Step 2: Weighing a certain amount of polyvinyl chloride and dissolving it in tetrahydrofuran organic solvent to form a 16% W / V polyvinyl chloride-tetrahydrofuran solution; the amount of polyvinyl chloride added is 10wt% of tetrahydrofuran;

[0043] Step 3: Under magnetic stirring, add the lanthanum nitrate-carbon nanotube powder obtained in step 1 into the polyvinyl chloride-tetrahydrofuran solution to form a lanthanum nitrate-carbon nanotube / polyvinyl chloride black colloid solution; the lanthanum nitrate-carbon nanotube The addition of pipe powder is 8wt.% of polyvinyl chloride;

[0044] Step 4: Add the plasticizer DOP and the crosslinking agent styrene into the lanthanum nitrate-carbon nanotube / polyvinyl chloride black colloid solution, stir evenly and pour it into a se...

Embodiment 3

[0047] Step 1: mixing lanthanum nitrate with acidified carbon nanotubes, then ultrasonic and ball milling; the amount of lanthanum nitrate added is less than 9wt.% of the acidified carbon nanotubes;

[0048] Step 2: Weighing a certain amount of polyvinyl chloride and dissolving it in a tetrahydrofuran organic solvent to form a 16% W / V polyvinyl chloride-tetrahydrofuran solution; the amount of polyvinyl chloride added is 20wt% of tetrahydrofuran;

[0049] Step 3: Under magnetic stirring, add the lanthanum nitrate-carbon nanotube powder obtained in step 1 into the polyvinyl chloride-tetrahydrofuran solution to form a lanthanum nitrate-carbon nanotube / polyvinyl chloride black colloid solution; the lanthanum nitrate-carbon nanotube The addition of pipe powder is 15wt.% of polyvinyl chloride;

[0050] Step 4: Add the plasticizer DOP and the crosslinking agent styrene into the lanthanum nitrate-carbon nanotube / polyvinyl chloride black colloid solution, stir evenly and pour it into a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com