Phenolic acid starch ester as well as preparation method and application thereof

A technology of starch ester and phenolic acid, which is applied in the field of food chemistry, can solve the problems that the impact on human health has not been clarified, achieve good biological activity, improve enzyme activity, and promote the effect of starch dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

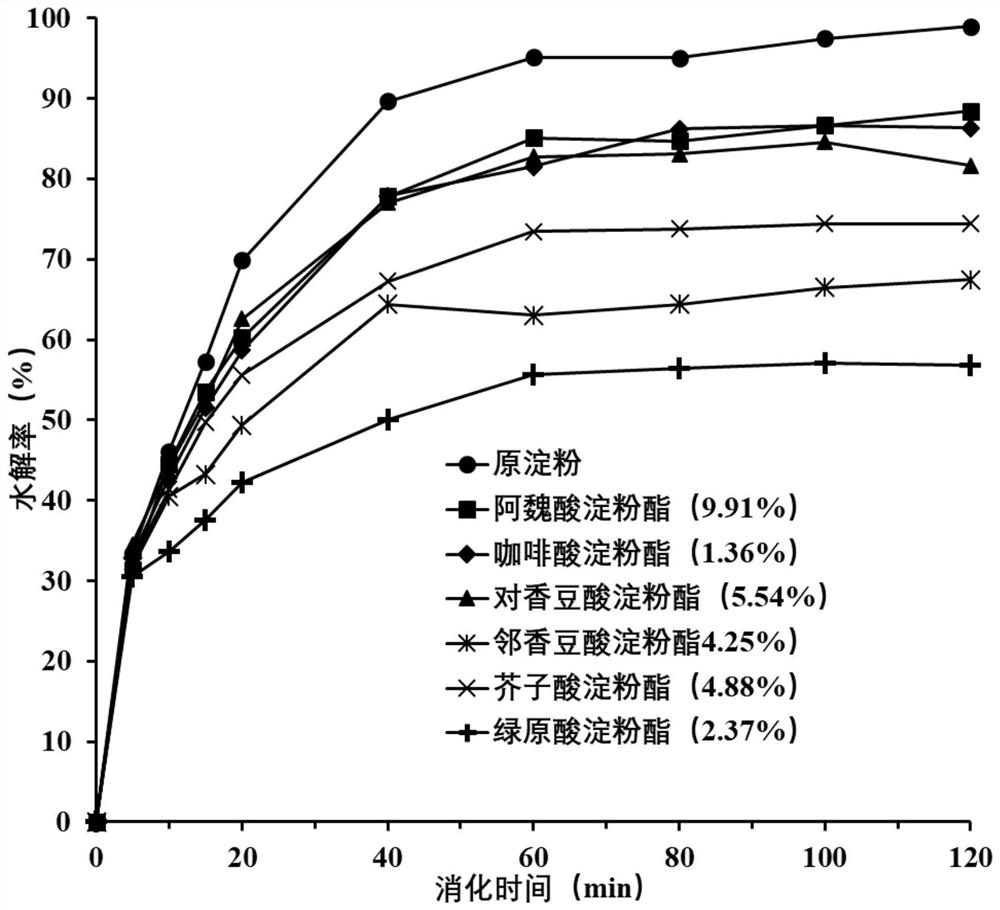

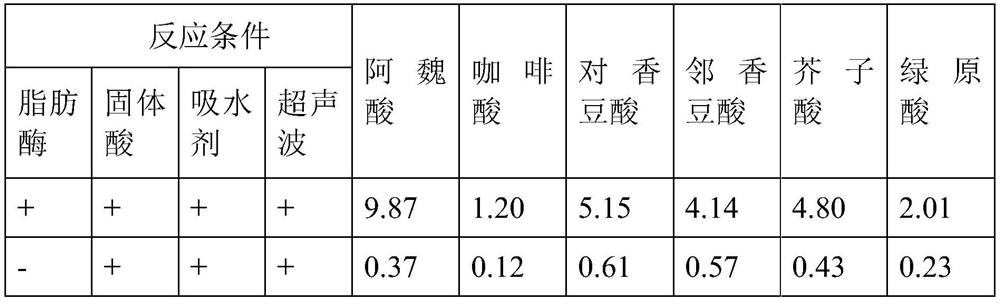

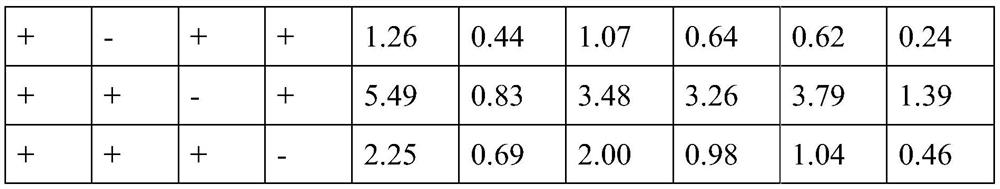

[0045] Add 10 g of starch into 200 mL of water and heat at 70° C. for 30 minutes for pregelatinization treatment, and then freeze-dry to obtain pregelatinized starch. Mix 5mmol ferulic acid, caffeic acid, p-coumaric acid, o-coumaric acid, sinapic acid, chlorogenic acid and 5mmol pregelatinized starch in isooctane, add or not add 10% (to pregelatinize Starch mass) lipase, 1% (pregelatinized starch mass) solid acid catalyst, and 10% (pregelatinized starch mass) water-absorbing agent, use or not use ultrasonic treatment, ultrasonic treatment conditions are: One kilogram of pregelatinized starch corresponds to an ultrasonic power of 50 watts; react at 60°C to observe the degree of substitution of the product. After reacting for 24 hours, filter through a 60-mesh sieve to remove the water-absorbing agent and solid acid catalyst, collect the filtrate, centrifuge at 2000r / min for 10min, wash the precipitate with 95% ethanol solution and then centrifuge again, repeat 2-3 times, and co...

Embodiment 2

[0052] Add 10 g of starch into 200 mL of water and heat at 70° C. for 30 minutes for pregelatinization treatment, and then freeze-dry to obtain pregelatinized starch. With 5mmol p-coumaric acid, sinapinic acid, or chlorogenic acid and 5mmol pregelatinized starch, 10% (by pregelatinized starch mass) lipase, 1% (by pregelatinized starch mass) solid acid catalyst, And 10% (based on the mass of pregelatinized starch) water-absorbing agent is mixed in isooctane, and placed at 20, 30, 40, 50, 60, 70, 80, 90 ° C for reaction, while ultrasonic treatment, reaction 3, 6 , 9, 12, 18, 24, 36, 48, 60 hours, keep stirring, and get the phenolic acid starch ester suspension through a 60-mesh sieve, remove the water-absorbing agent and solid acid catalyst, collect the filtrate, and centrifuge at 2000r / min After 10 minutes, the precipitate was washed with 95% ethanol solution and centrifuged again, and repeated 2 to 3 times. The combined supernatant could be recovered by removing the solvent, a...

Embodiment 3

[0063] Add 10 g of cassava, sweet potato, potato, corn and wheat starch to 200 mL of water and heat at 70°C for 30 minutes for pre-gelatinization treatment, and then freeze-dry to obtain pre-gelatinized starch. 5mmol of ferulic acid, caffeic acid, p-coumaric acid, o-coumaric acid, sinapic acid or chlorogenic acid and 5mmol of pregelatinized starch, 10% (by pregelatinized starch mass) lipase, 1% (by Pre-gelatinized starch mass) solid acid catalyst, and 20% (pre-gelatinized starch mass) water-absorbing agent mixed in isooctane, and placed at 70 ° C for reaction, while ultrasonic treatment, reaction for 24 hours, stirring constantly, The phenolic acid starch ester suspension was coarsely filtered through a 60-mesh sieve to remove the water-absorbing agent and solid acid catalyst, collect the filtrate, centrifuge at 2000r / min for 10min, add 95% ethanol solution to the precipitate and wash it, and then centrifuge again, repeating 2 to 3 times. The combined supernatant can be recove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com