Degradable PLA for data line protection sleeve and preparation method of degradable PLA

A technology of protective cover and data cable, applied in the field of degradable PLA material and its preparation, can solve the problems of hidden danger of fire, flammability of PLA protective cover, easy to expand fire, etc., to improve anti-aging, improve fire safety, The effect of not easy to aging and deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

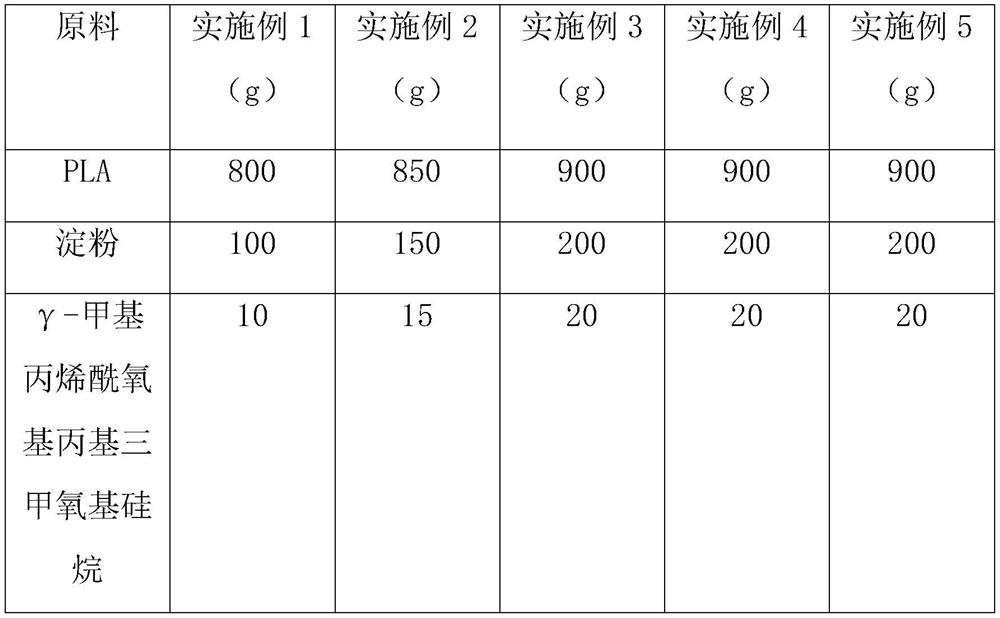

Embodiment 1-5

[0034] The following is illustrated by taking Example 1 as an example. The degradable PLA material used for the data line protective sleeve includes the following steps:

[0035] Raw material drying: bake the PLA masterbatch at 70°C for 10 hours, and bake the starch at 50°C for 10 hours to obtain dry PLA masterbatch and starch;

[0036] Melt blending: weigh each raw material according to Table 1, melt and blend each raw material for 15 minutes, and the melting temperature is 170°C to obtain a blend; extrusion granulation: crush the blend and put it into an extruder to melt and extrude out, and then cutting and granulating to obtain a degradable PLA material for the data cable protective cover, with a particle size of 2-4mm; the extruder has 4 temperature ranges from the feed port to the discharge port, and the temperature in each range The temperature from the feed inlet to the discharge outlet is 150°C, 155°C, 160°C, and 170°C respectively, and the temperature near the feed i...

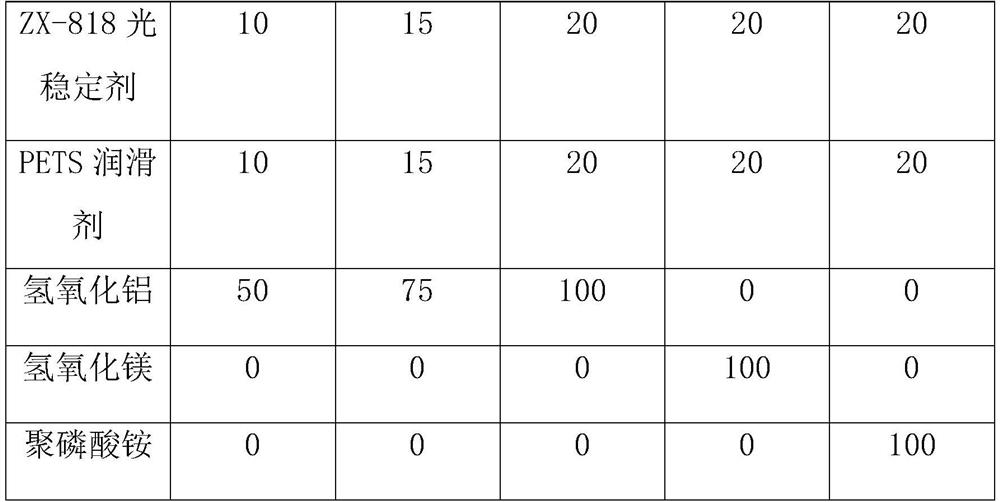

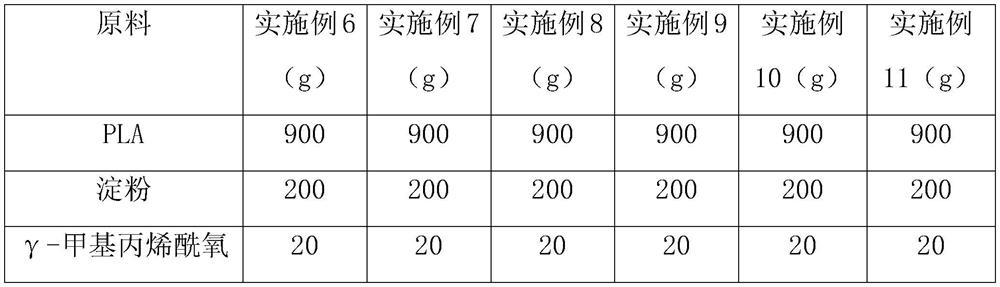

Embodiment 6-11

[0042] As shown in Table 2, compared with Example 5, the main difference of the degradable PLA material used for the data line protective sleeve of Examples 6-11 is that the raw materials have increased resorcinol bis (diphenyl phosphate), At least one of hydroquinone bis(diphenyl phosphate) or hydroquinone bis[bis(1-methyl-2-phenyl phosphate)].

Embodiment 6

[0043] The difference between the preparation method of embodiment 6 and the preparation method of embodiment 5 is that in the melt mixing process, according to the difference between resorcinol bis(diphenyl phosphate) and hydroquinone bis(diphenyl phosphate) And the weight ratio with ammonium polyphosphate is that 1:1 has added resorcinol bis(diphenyl phosphate) and hydroquinone bis(diphenyl phosphate); The preparation method of embodiment 7 is the same as that of embodiment 5 The difference of the preparation method is that during the melt mixing process, the weight ratio of resorcinol bis(diphenyl phosphate) to ammonium polyphosphate is 1:2, adding resorcinol bis(diphenyl phosphate) ); the preparation method of embodiment 8-9 is the same as embodiment 7; the difference between the preparation method of embodiment 10 and the preparation method of embodiment 5 is that in the melt mixing process, press hydroquinone bis[two (1- The weight ratio of methyl-2-phenyl phosphate)] an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com