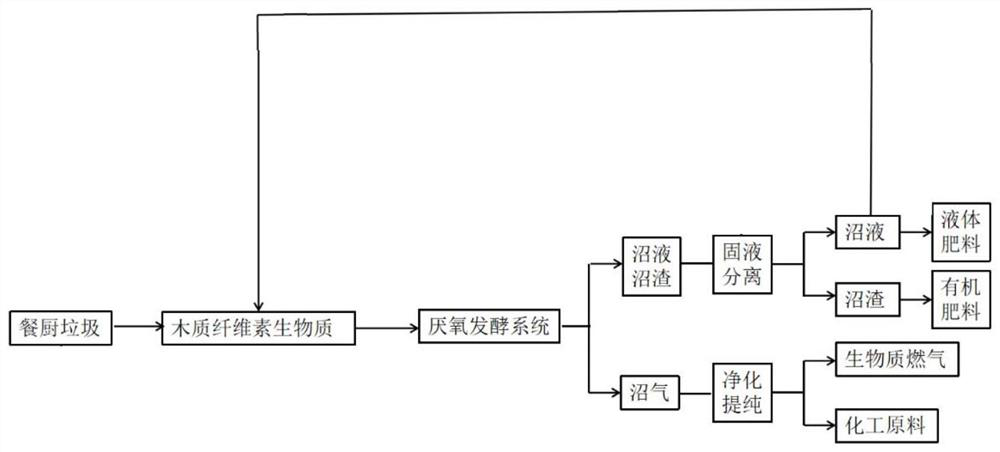

Lignocellulose biomass anaerobic fermentation method adopting biogas slurry and kitchen waste combined pretreatment

A lignocellulose and anaerobic fermentation technology, which is applied in the field of anaerobic fermentation of lignocellulosic biomass combined with biogas slurry and kitchen waste pretreatment, can solve the problems of poor operability and high pretreatment cost, and achieves simple and improved methods. Biodegradability, improving the effect of efficient utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

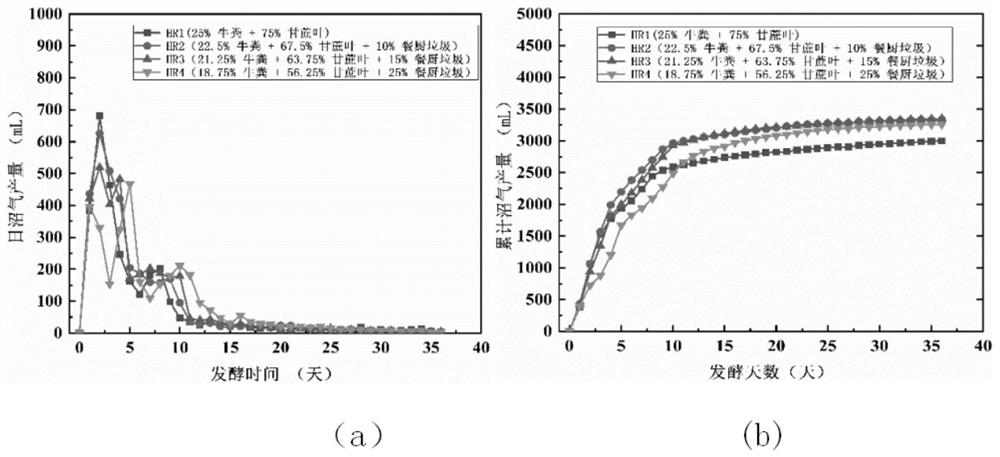

[0035] Example 1 Biogas production in mixed anaerobic fermentation of different proportions of livestock and poultry manure and crop straw

[0036] 1. Experimental method

[0037] S1. Crush the cow dung and sugarcane straw after solid-liquid separation, and pass through a 40-mesh sieve for later use. The ratio of cow dung and crop straw is 15:85, 25:75, 35:65, 50:50, and 65, respectively. : 35, 75: 25, 85: 15 were mixed and pulverized. In addition, separate cow dung and sugarcane straw were used as controls;

[0038] S2. Pass the biogas slurry and biogas residue after the anaerobic fermentation reaction through a 40-mesh sieve for solid-liquid separation, and put the biogas slurry into a closed bottle and let it stand until no more biogas is produced, and set aside;

[0039] S3. Add the biogas slurry in step S2 to the crushed lignocellulosic biomass in step S1 and mix, so that the TS concentration of the mixture is 15%;

[0040] S4. Add kitchen waste to the mixture obtained ...

Embodiment 2

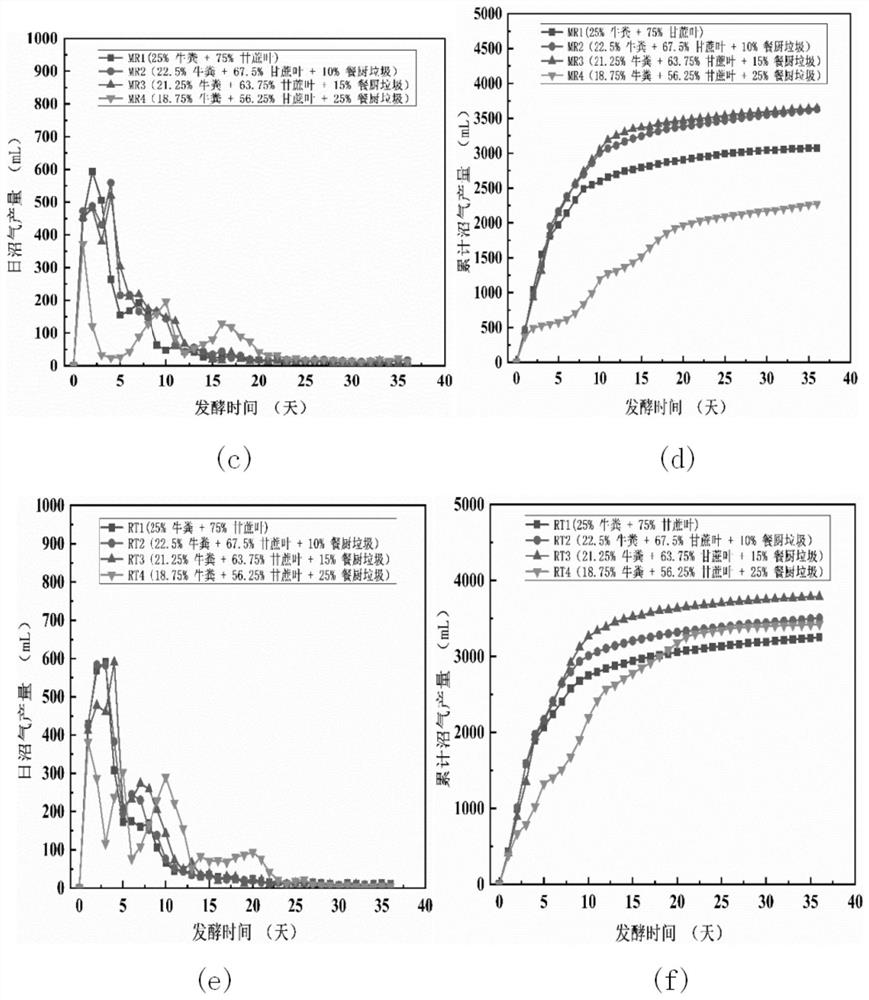

[0046] Example 2 Biogas production in anaerobic fermentation at different temperatures and different kitchen waste addition ratios

[0047] 1. Experimental method

[0048] S1. Mix and pulverize the cow dung and sugarcane stalks after solid-liquid separation according to the VS ratio of 1:3, pass through a 40-mesh sieve, and set aside;

[0049] S2. Pass the biogas slurry and biogas residue after the anaerobic fermentation reaction through a 40-mesh sieve for solid-liquid separation, and put the biogas slurry into a closed bottle and let it stand until no more biogas is produced, and set aside;

[0050] S3. Add the biogas slurry in step S2 to the crushed lignocellulosic biomass in step S1 and mix, so that the TS concentration of the mixture is 15%;

[0051]S4. Add kitchen waste to the mixture obtained in step S3, pretreat at 55°C, 37°C, and 25°C for 4, 5, and 6 days, and mechanically stir once every 0.5 hours to make the flora and bio-acids Fully contact with lignocellulosic b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com