Preparation method and application of unilateral sensitive flexible film with micro-nano composite structure

A micro-nano composite structure and flexible film technology, which is applied in the field of flexible gas and humidity sensing, can solve the problems that cannot affect the response characteristics of the sensor, and achieve good response bending stability, avoid enrichment, and avoid direct contact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] ①The first step is to prepare 0.001 mol / L sodium dodecylbenzenesulfonate and 0.3 mol / L aniline sulfate aqueous solution, and 0.5 mol / L potassium persulfate and 1 mol / L camphorsulfonic acid aqueous solution, and the above two aqueous solutions Stir to dissolve and mix well.

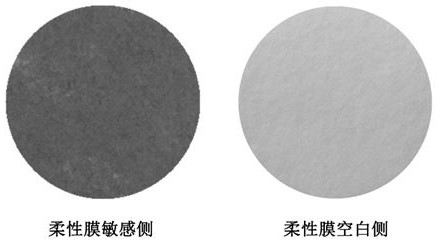

[0042] ② Float the hydrophobic polypropylene (PP) microporous membrane on the mixed solution prepared in step 1), polymerize at -5°C for 4 h, wash, and dry at 70°C to obtain a single membrane with a micro-nano composite structure. Side-sensitive polyaniline (PANI) / PP flexible film. After cutting the flexible film as the sensing element of the sensor, and connecting it to the corresponding external circuit, a wearable flexible film gas or humidity sensor can be produced. This kind of application is relatively straightforward for those skilled in the art, and existing technical solutions can be adopted.

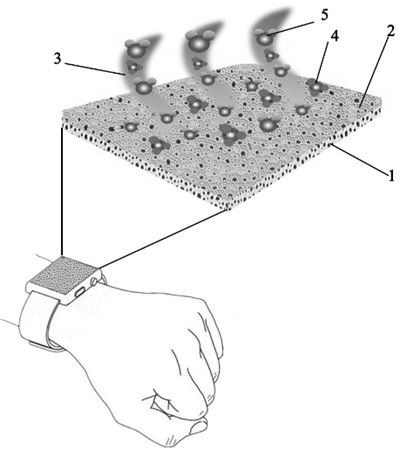

[0043] figure 1 It is the working principle diagram corresponding to the one-sided sensitive f...

Embodiment 2

[0047] ① In the first step, prepare 0.03 mol / L sodium dodecylbenzene sulfonate and 1 mol / L aniline sulfate aqueous solution, and 0.05 mol / L ammonium persulfate and 0.5 mol / L polystyrene sulfonic acid aqueous solution. The aqueous solution was stirred to dissolve and then mixed evenly.

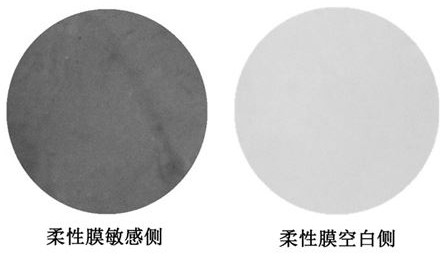

[0048] ② Float the hydrophobic PP microporous membrane on the mixed solution prepared in step 1), polymerize at 3 °C for 24 h, wash, and dry at 150 °C to obtain a single-sided sensitive PANI / PP flexible film; can be fabricated into a wearable flexible film NH 3 gas sensor.

[0049] Figure 10 The wearable flexible film NH prepared for the one-sided sensitive PANI / PP flexible film with micro-nano composite structure obtained in Example 2 of the present invention 3 Gas sensor for different concentrations of NH 3 The dynamic response result graph. Regulation of NH in the test chamber by a dynamic gas distribution process 3 Concentrations of 0, 0.5, 1, 2, 3, 5, 8 and 10 ppm, PANI / PP wearable...

Embodiment 3

[0051] ① In the first step, prepare 0.05 mol / L sodium cetyl sulfate and 0.7 mol / L aniline hydrochloride aqueous solution, and 1 mol / L ammonium persulfate and 1 mol / L polystyrene sulfonic acid aqueous solution, and stir the above two aqueous solutions Mix well after dissolving.

[0052] ② Float the hydrophobic polytetrafluoroethylene (PTFE) microporous membrane on the mixed solution prepared in step 1), polymerize at 0°C for 8 hours, wash, and dry at 110°C to obtain a micro-nano composite structure One-sided sensitive PANI / PTFE flexible membrane; can be prepared into a wearable flexible membraneNO 2 gas sensor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com