Method for recovering cobalt in cobalt chloride wastewater based on two-stage resin separation

A resin separation and recovery method technology, applied in chemical instruments and methods, water pollutants, water/sewage treatment, etc., can solve the problems of long dark spots on the surface of cobalt-based materials, adverse effects of deep purification of cobalt solution, and high operating costs , to extend the hydraulic retention time, improve the efficiency of wastewater treatment, and reduce operating costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

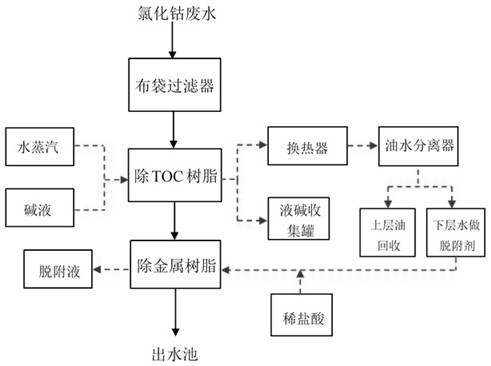

Image

Examples

Embodiment 1

[0031] The cobalt chloride wastewater in this example is cobalt chloride production wastewater from a company in Taizhou. The wastewater TOC is about 202 mg / L, the Cd concentration is 1.9 mg / L, and the Co concentration is 1.6×10 5 mg / L, solution pH 4.5, the treatment steps for this waste water are:

[0032] (1) Filtration: waste water with 4m 3 The flow rate of / h flows through the bag filter to remove suspended solids in the wastewater.

[0033] (2) Primary resin adsorption: Send the filtered wastewater to the lower end of the adsorption device filled with macroporous non-polar special adsorption resin, and perform countercurrent adsorption to remove organic matter in the wastewater. The aspect ratio of macroporous non-polar special adsorption resin is 3:1, and 50BV wastewater is adsorbed at a flow rate of 3.5BV / h, and the resin effluent TOC is reduced to 26.79mg / L.

[0034] (3) Secondary resin adsorption: Send the effluent of the primary resin to the secondary adsorption d...

Embodiment 2

[0040] The cobalt chloride wastewater in this example is cobalt chloride production wastewater from a new energy material company in Tianjin. The wastewater TOC is about 147 mg / L, the Cd concentration is 2.316 mg / L, and the Co concentration is 1.95×10 5 mg / L, solution pH 3.9, the treatment steps for this waste water are:

[0041] (1) Filtration: waste water with 5 m 3 The flow rate of / h flows through the bag filter to remove suspended solids in the wastewater.

[0042] (2) Primary resin adsorption: Send the filtered wastewater to the lower end of the adsorption device filled with macroporous non-polar special adsorption resin, and perform countercurrent adsorption to remove organic matter in the wastewater. The macroporous non-polar special adsorption resin is loaded with a height-to-diameter ratio of 3:1, and absorbs 65 BV of wastewater at a flow rate of 4 BV / h, and the TOC of the resin effluent is reduced to 9.4 mg / L.

[0043] (3) Secondary resin adsorption: Send the efflue...

Embodiment 3

[0046] The waste water in this example is cobalt chloride waste water produced by an ultrafine powder material production company in Hubei. The waste water TOC is about 317 mg / L, the Cd concentration is 1.739 mg / L, and the Co concentration is 2.01×10 5 mg / L, solution pH 4.8, the treatment steps for this waste water are:

[0047] (1) Filtration: waste water with 5 m 3 The flow rate of / h flows through the bag filter to remove suspended solids in the wastewater.

[0048] (2) Primary resin adsorption: Send the filtered wastewater to the lower end of the adsorption device filled with macroporous non-polar special adsorption resin, and perform countercurrent adsorption to remove organic matter in the wastewater. The aspect ratio of macroporous non-polar special adsorption resin is 3.5:1, and 45 BV wastewater is adsorbed at a flow rate of 3 BV / h. The resin effluent TOC is reduced to 43.7 mg / L, and 80% of the primary resin effluent is refluxed to At the water inlet, repeat the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com