Viscosity reducing agent and preparation method thereof and method for reducing viscosity of fermentation mash

A technology for fermentation mash and viscosity reducing agent, applied in the field of fermentation, can solve the problems of low feasibility and low economic benefit of fermented mash, and achieve the effects of reducing advantages, being suitable for large-scale promotion and use, and having a wide range of sources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0041] According to a particularly preferred embodiment of the present invention, the method for preparing the viscosity reducer comprises:

[0042] (1) Dissolve lignin in 0.05-0.5mol / L alkali metal hydroxide solution, then add formaldehyde until the volume concentration of formaldehyde is 0.2-3%, then react at 60-100°C for 30-90min, then adding sulfurous acid with 0.5-5wt% of the total mass of lignin, reacting at 70-90°C for 20-60min, then adjusting the pH of the system to 3-4, then centrifuging, washing, and drying to obtain lignosulfonate;

[0043] (2) Under water-containing conditions, the lignosulfonate and the aluminum source are mixed and dissolved at a mass ratio of 1-4:1 to obtain a mixed solution;

[0044] (3) In the presence of a noble metal catalyst, the mixed solution is subjected to a catalytic reaction at 40-80° C. for 20-50 minutes to obtain a viscosity reducer solution;

[0045] (4) Drying the viscosity reducer solution to obtain the viscosity reducer quality...

preparation example 1

[0050] (1) Dissolve lignin in 0.2mol / L sodium hydroxide solution, then add formaldehyde until the volume concentration of formaldehyde is 1%, and then react at 80°C for 50min to obtain the mixed system A;

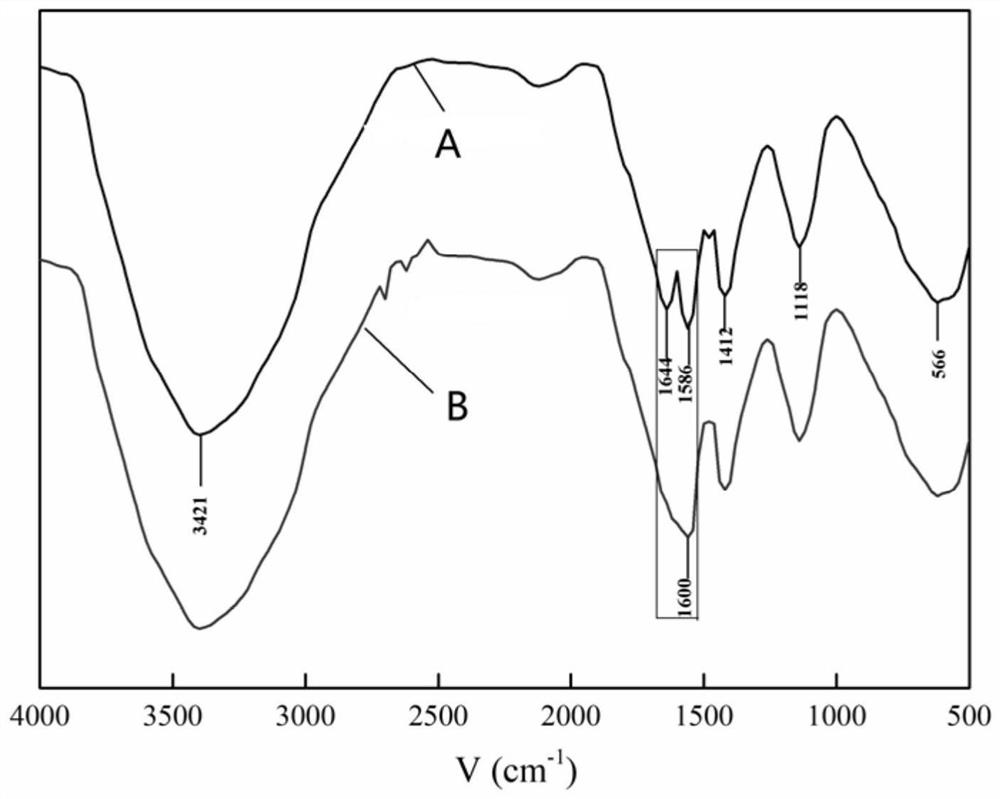

[0051] Add sulfurous acid with a total lignin content of 2wt% to the mixed system A, react at 85°C for 30 minutes, then adjust the pH of the system to 3-4, then centrifuge, wash and dry to obtain sodium lignosulfonate, its infrared spectrum Such as figure 1 shown;

[0052] (2) Sodium lignosulfonate and aluminum chloride are stirred and dissolved in water according to the mass ratio of 1.5:1 to obtain a mixed solution;

[0053] (3) Put the mixed solution of step (2) into a shaker, and add a platinum calcium carbonate catalyst into the mixed solution at a shaking speed of 100rpm / min (the concentration of platinum calcium carbonate in the mixed solution is 1wt%) , catalyzed at 75°C for 40 minutes to obtain a viscosity reducer solution;

[0054] Dry the viscosity reducer sol...

preparation example 2

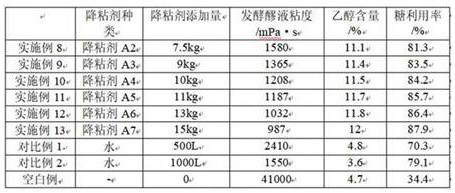

[0057] According to the method of Example 1, the difference is that the molecular weight of lignin is 1000, and the viscosity reducer A2 is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com