Ti5Si3 nanostructure reinforced TiC biological ceramic coating as well as preparation method and application thereof

A technology of bioceramics and nanostructures, which is applied in coatings, metal material coating processes, drug delivery, etc., to achieve the effects of low process cost, good market application prospects, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

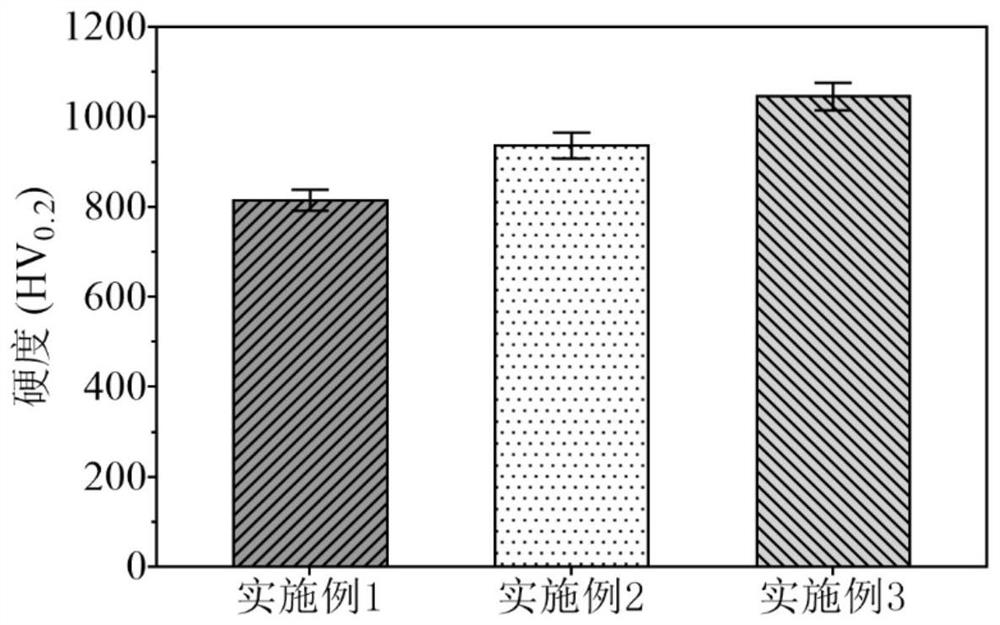

Embodiment 1

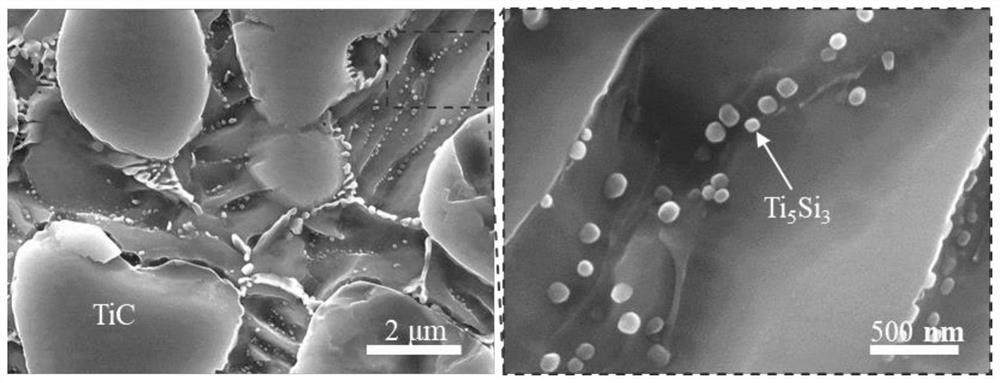

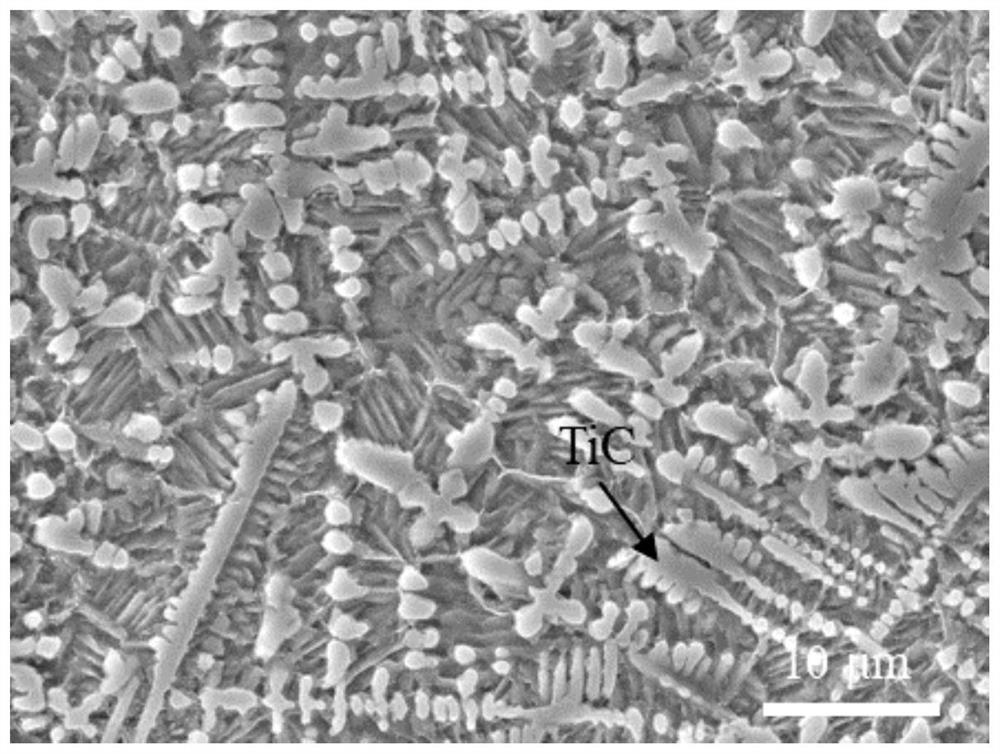

[0038] A kind of Ti of the present invention 5 Si 3 A method for preparing a nanostructure-enhanced TiC bioceramic coating, comprising the following steps:

[0039] (1) TiC powder with a mass fraction of 90% (particle size is 40-60nm, purity ≥ 99.5%) and SiO with a mass fraction of 10% 2 Powder (3-6 μm in particle size, purity ≥ 99.9%) is added to a planetary ball mill and mixed evenly to obtain a mixed powder, the ball milling speed is 200rmp / min, and the ball milling time is 2h; the mixed powder is added to polyvinyl alcohol with a concentration of 1% vol In the aqueous solution, the mass ratio of the mixed powder and the polyvinyl alcohol aqueous solution is 0.45:2.8, and the stirring is continued, and then the ultrasonic vibration treatment is performed until the mixing is uniform, and the slurry is obtained; the Ti 6 al 4 The V titanium alloy plate is used as the base, and the size of the base is 30mm×30mm×6mm. The surface of the base is polished with 100-grit sandpape...

Embodiment 2

[0043] A kind of Ti of the present invention 5 Si 3 A method for preparing a nanostructure-enhanced TiC bioceramic coating, comprising the following steps:

[0044] (1) TiC powder with a mass fraction of 80% (particle size is 40-60nm, purity ≥ 99.5%) and SiO with a mass fraction of 20% 2 Powder (3-6 μm in particle size, purity ≥ 99.9%) is added to a planetary ball mill and mixed evenly to obtain a mixed powder, the ball milling speed is 200rmp / min, and the ball milling time is 2h; the mixed powder is added to polyvinyl alcohol with a concentration of 1% vol In the aqueous solution, the mass ratio of the mixed powder and the polyvinyl alcohol aqueous solution is 0.45:2.8, and the stirring is continued, and then the ultrasonic vibration treatment is performed until the mixing is uniform, and the slurry is obtained; the Ti 6 al 4 The V titanium alloy plate is used as the base, and the size of the base is 30mm×30mm×6mm. The surface of the base is polished with 100-grit sandpape...

Embodiment 3

[0049] A kind of Ti of the present invention 5 Si 3 A method for preparing a nanostructure-enhanced TiC bioceramic coating, comprising the following steps:

[0050] (1) TiC powder with a mass fraction of 70% (particle size is 40-60nm, purity ≥ 99.5%) and SiO with a mass fraction of 30% 2 Powder (3-6 μm in particle size, purity ≥ 99.9%) is added into a planetary ball mill and mixed evenly to obtain a mixed powder, the ball milling speed is 200rmp / min, and the ball milling time is 2h; the mixed powder is added to polyvinyl alcohol with a concentration of 1% vol In the aqueous solution, the mass ratio of the mixed powder and the polyvinyl alcohol aqueous solution is 0.45:2.8, and the stirring is continued, and then the ultrasonic vibration treatment is performed until the mixing is uniform, and the slurry is obtained; the Ti 6 al 4 The V titanium alloy plate is used as the base, and the size of the base is 30mm×30mm×6mm. The surface of the base is polished with 100-grit sandpa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fracture toughness | aaaaa | aaaaa |

| Volume wear | aaaaa | aaaaa |

| L | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com