Titanium alloy surface anti-fouling composite coating as well as preparation method and application thereof

A technology of composite coating and titanium alloy, which is applied in the direction of surface reaction electrolytic coating, metal material coating process, and device for coating liquid on the surface, etc. Industrial production and other problems, to achieve the effect of preventing fouling and biological adhesion, preventing biological adhesion, and low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

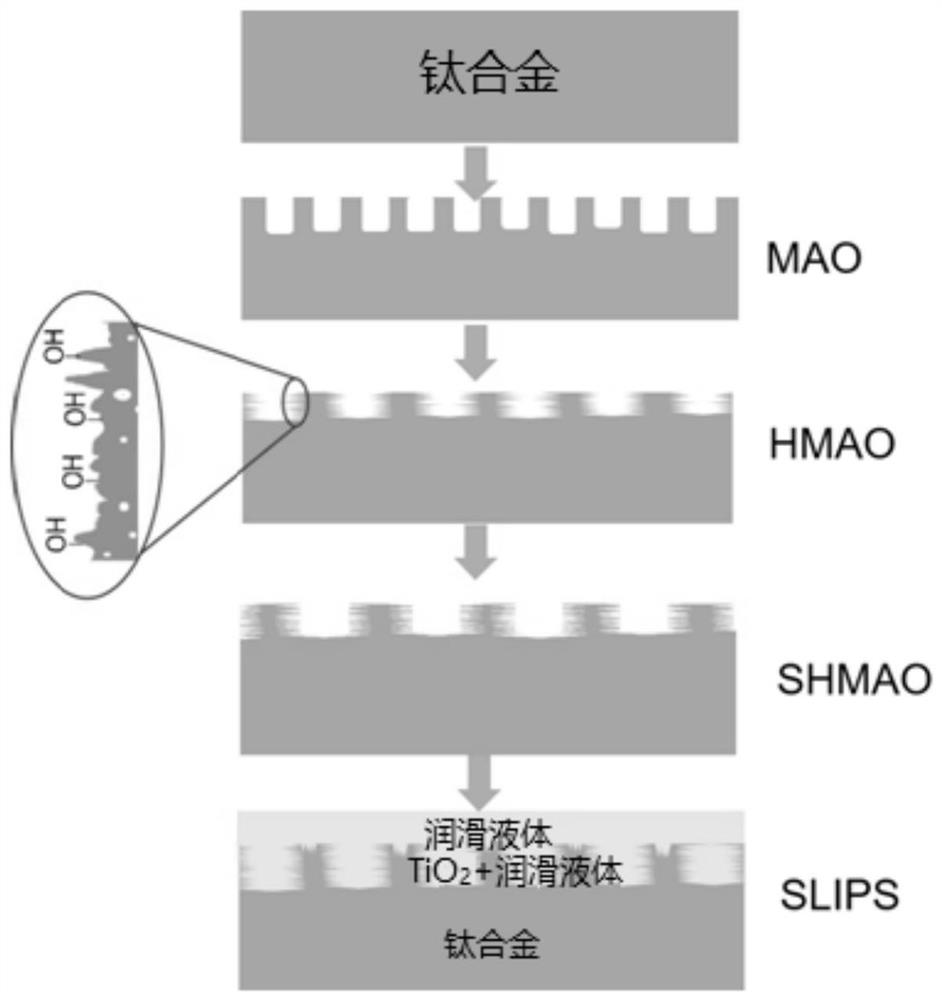

[0059] A method for preparing an antifouling composite coating on the surface of a titanium alloy, the preparation process of which is as follows figure 1 As shown, it specifically includes the following steps:

[0060] (1) Pretreatment

[0061] Using 80-mesh brown corundum sand grains, the surface of the TA2 titanium alloy sample is uniformly sandblasted by a sandblasting machine, so that the surface of the TA1 titanium alloy sample forms a uniform rough surface. Then use acetone and ethanol to perform ultrasonic cleaning for about 30 minutes to degrease and clean the surface, and then vacuum dry.

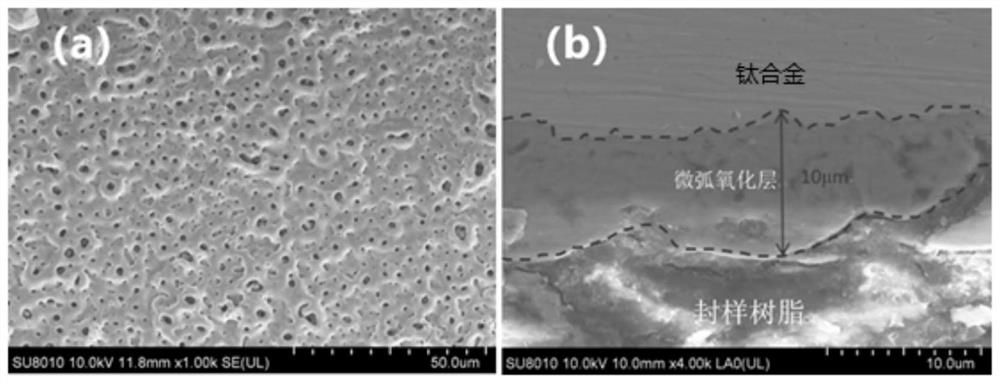

[0062] (2) Micro-arc oxidation surface treatment

[0063] In the electrolyte, the sample after the above pretreatment is used as the anode, 304 stainless steel is used as the cathode, and a 30kW bipolar pulsed micro-arc oxidation power supply is used for micro-arc oxidation treatment to form a ceramic porous structure on the surface of the titanium alloy.

[0064] The compositi...

Embodiment 2

[0082] Micro-arc oxidation technology is used to prepare ceramic porous structure on the surface of titanium alloy, which specifically includes the following steps:

[0083] (1) Pretreatment

[0084]Using 80-mesh brown corundum sand grains, the surface of the TA1 titanium alloy sample is uniformly sandblasted by a sandblasting machine, so that the surface of the TA1 titanium alloy sample forms a uniform rough surface. Then use acetone and ethanol to perform ultrasonic cleaning for about 30 minutes to degrease and clean the surface, and then vacuum dry.

[0085] (2) Micro-arc oxidation surface treatment

[0086] In the electrolyte, the above-mentioned pretreated sample is used as the anode, 304 stainless steel is used as the cathode, and a 30KW bipolar pulse micro-arc oxidation power supply is used for micro-arc oxidation treatment to form a ceramic porous structure on the surface of the titanium alloy.

[0087] Wherein the electrolyte consists of:

[0088] Electrolyte 1: so...

Embodiment 3

[0102] Using micro-arc oxidation technology to prepare a ceramic porous structure on the surface of titanium alloy, and then grow a ceramic composite micro-nano porous structure in-situ in the ceramic porous structure, which specifically includes the following steps:

[0103] (1) Pretreatment

[0104] Using 80-mesh brown corundum sand grains, the surface of the TA1 titanium alloy sample is uniformly sandblasted by a sandblasting machine, so that the surface of the TA1 titanium alloy sample forms a uniform rough surface. Then use acetone and ethanol to perform ultrasonic cleaning for about 30 minutes to degrease and clean the surface, and then vacuum dry.

[0105] (2) Micro-arc oxidation surface treatment

[0106] In the electrolyte, the above-mentioned pretreated sample is used as the anode, 304 stainless steel is used as the cathode, and a 30KW bipolar pulse micro-arc oxidation power supply is used for micro-arc oxidation treatment to form a ceramic porous structure on the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com