A kind of preparation method of antioxidant fiber additive for vegetable protein meat

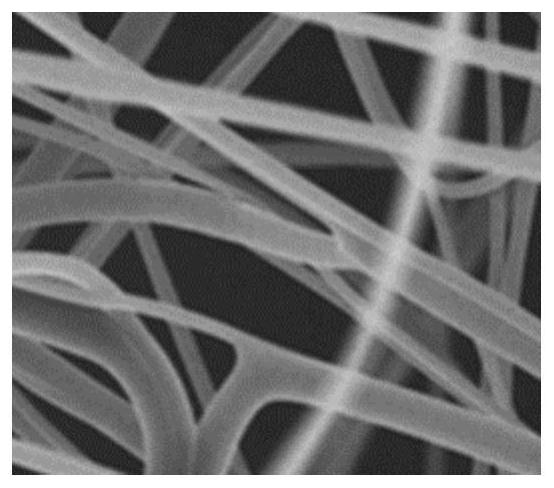

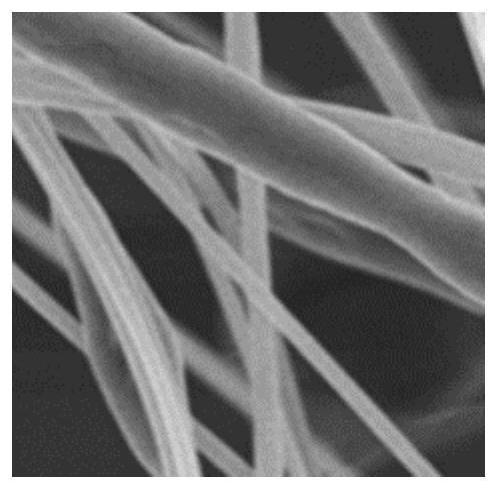

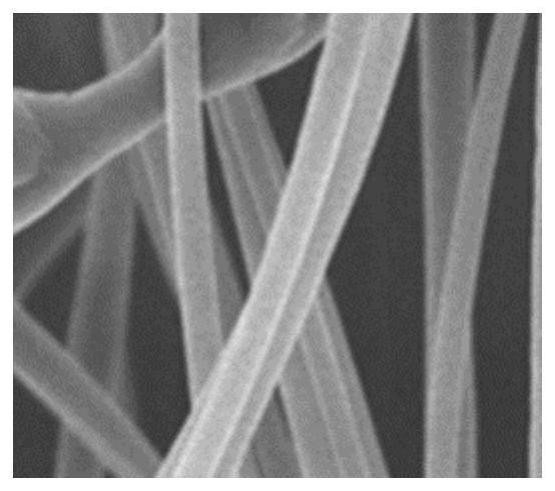

A plant protein and additive technology, which is applied in plant protein processing, protein food processing, and textured treatment, can solve the problems of easy oxidation, cis-trans isomerization, bad flavor, etc., and achieve the improvement of lipid oxidation stability Sexuality, small size, uniform distribution of antioxidants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Dissolve: First, 20% aqueous aqueous acetic acid, then add gelatin powder to aqueous aqueous aqueous solution until the gelatin mass fraction reached 18%, 300 rpm stir for 2 h, so that gelatin is good to dissolve, and gelatin solution;

[0039] Formaging solution: The vitamin E, soy lecithin is added to the above gelatin solution until the mass fraction of vitamin E reaches 2%, and the mass fraction of soy lecithin reaches 2%, at a high speed disperser for 3 min, and the speed is 12000 rpm, then The homogeneous cycle is placed in a high pressure homogeneous machine, and the pressure is 75 MPa, and finally a fibrous solution is obtained.

[0040] Degassing: The above-mentioned fiber solution was placed in a centrifuge for 3 min, the centrifugal force was 2000 g, and the bubble in the solution was removed.

[0041] Solution Spray Spray: In the relative humidity of 50%, the temperature is 20 ° C, the fibrous solution is placed in the feed pump, and the material pumps the mater...

Embodiment 2

[0043] Dissolve: 50% aqueous aqueous aqueous acetic acid, then adding methylcellulose powder to aqueous aqueous acetic acid until the methyl cellulose mass fraction reaches 5%, 300 rpm stir for 2 h, so that methylcellulose is well dissolved, and the methylcellulose solution is obtained.

[0044] Formaging solution: The vitamin E, soy lecithin is added to the above gelatin solution until the mass fraction of vitamin E reaches 2%, and the mass fraction of soy lecithin reaches 2%, at a high speed disperser for 3 min, and the speed is 12000 rpm, then The homogeneous cycle is placed in a high pressure homogeneous machine, and the pressure is 75 MPa, and finally a fibrous solution is obtained.

[0045] Degassing: The above-mentioned fiber solution was placed in a centrifuge for 3 min, the centrifugal force was 2000 g, and the bubble in the solution was removed.

[0046] Solution Spray Spray: In the relative humidity of 50%, the temperature is 20 ° C, the fibrous solution is placed in th...

Embodiment 3

[0048] Dissolve: The aqueous aqueous acetic acid is prepared, and then the corn alcohol is added to aqueous aqueous aqueous solution until the corn alcohol protein mass fraction reaches 40%, and 300 rpm is stirred for 2 h, so that the corn alcohol is good to dissolve, and the corn allowation protein solution is obtained.

[0049] Formaging solution Preparation: Add vitamin E, soy lecithin to the above gelatin solution until the mass fraction of vitamin E reaches 2%, the mass fraction of soy lecithin reaches 2%, the mixture is stirred at a high speed distribution machine for 3 min, and the speed is 12000 rpm. Subsequently, the homogeneous cycle is placed in a high pressure homogeneous machine, and the pressure is 75 MPa, and finally a fibrous solution is obtained.

[0050] Degassing: The above-mentioned fiber solution was placed in a centrifuge for 3 min, the centrifugal force was 2000 g, and the bubble in the solution was removed.

[0051] Solution Spray Spray: In the relative hum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com