Preparation method of p-anisidine

A technology for p-aminoanisole and p-nitroanisole, which is applied in the field of preparation of p-aminoanisole, can solve the problems of large amount of solvent methanol, difficult temperature control, increase of by-products and the like, and achieves an increase in the production capacity of a single kettle , The effect of the substrate reaction is complete and the daily production capacity is improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

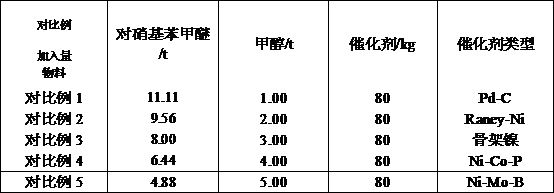

Examples

preparation example Construction

[0025] In a specific embodiment, a method for preparing p-aminoanisole comprises using p-nitroanisole as a raw material and performing hydrogenation in a hydrogenation kettle to prepare p-aminoanisole. Include the following steps:

[0026] S11. Add methanol and catalyst, and under the protection of inert gas, add methanol, catalyst and co-catalyst to the hydrogenation tank.

[0027] Under the protection of inert gas, preferably nitrogen, add methanol, catalyst and cocatalyst to the hydrogenation tank. The dosage of methanol is 1 / 12 to 2 / 5 of the maximum allowable liquid level of the hydrogenation tank. The catalyst is one of Pd-C catalyst, supported nickel catalyst or Raney nickel catalyst. The dosage of catalyst is: start The dosage of the first tank of production is 0.15 to 0.75 times of the theoretical mass of methanol, and the later production is supplemented according to the actual loss of the catalyst.

[0028] It is worth noting that before adding methanol and catalys...

Embodiment 1

[0053] Add methanol, catalyst and co-catalyst to the hydrogenation tank first. The amount of methanol added is 1 ton, the amount of catalyst (Raney-Ni) added is 80 kg, and the amount of co-catalyst added is 0.1 kg. After nitrogen replacement and hydrogen replacement to remove oxygen, the pressure was maintained at 1.0 MPa, the temperature was raised to 50 °C, and the catalyst was activated for 1 h. Add p-nitroanisole to the hydrogenation tank at a flow rate of 1.5 t / h, and carry out hydrogenation reaction at a hydrogen pressure of 1.2 MPa and a reaction temperature of 80 °C until the liquid level of the hydrogenation tank reaches 60% , stop adding p-nitroanisole, and carry out sampling analysis, until the content of p-nitroanisole in the reaction solution≤0.05%, the reaction is terminated. After the hydrogenation reaction is completed, the material is cooled and discharged, and the carried catalyst is removed by filtration, and methanol is distilled off to obtain p-aminoanisol...

Embodiment 2

[0055] Add methanol, catalyst and co-catalyst to the hydrogenation tank first. The amount of methanol added is 2 t, the amount of catalyst (Raney-Ni) added is 80 kg, and the amount of co-catalyst added is 0.1 kg. After nitrogen replacement and hydrogen replacement to remove oxygen, the pressure was maintained at 1.0 MPa, the temperature was raised to 50 °C, and the catalyst was activated for 1 h. Add p-nitroanisole to the hydrogenation tank at a flow rate of 1.8 t / h, and carry out hydrogenation reaction at a hydrogen pressure of 1.2 MPa and a reaction temperature of 80 °C until the liquid level of the hydrogenation tank reaches 60% , stop adding p-nitroanisole, and carry out sampling analysis, until the content of p-nitroanisole in the reaction solution≤0.05%, the reaction is terminated. After the hydrogenation reaction is completed, the material is cooled and discharged, and the carried catalyst is removed by filtration, and methanol is distilled off to obtain p-aminoanisole....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com